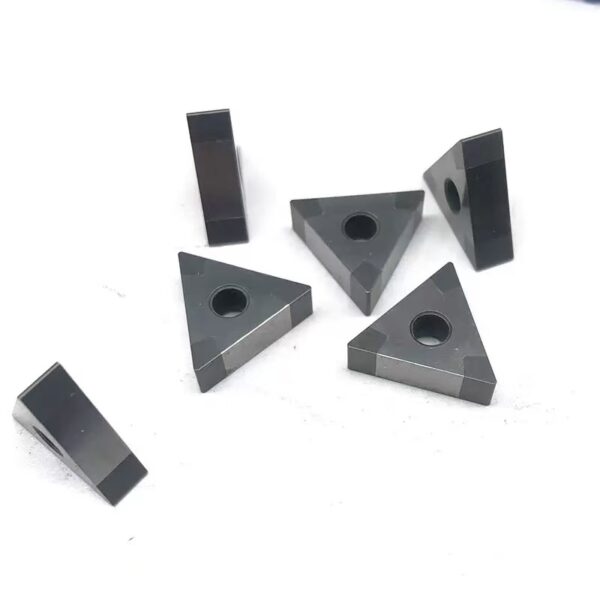

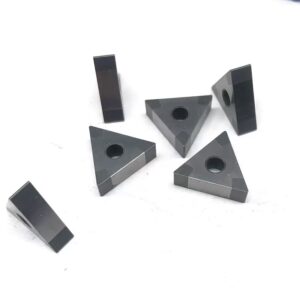

Ultra Hard Special CBN Inserts Ideal for Hardened Steel Cast Iron Machining

0 out of 5

Ultra Hard Special CBN Inserts Ideal for Hardened Steel Cast Iron Machining

Danh mục: Threaded Inserts

Thẻ: cbn cutting inserts, cbn grooving inserts, cbn inserts, cbn inserts for hard turning, cbn lathe inserts, cbn milling inserts, cbn threading inserts, cbn turning inserts, sheet metal threaded inserts, solid cbn inserts, stainless steel threaded inserts, threaded inserts, threaded inserts for concrete, threaded inserts for metal, threaded inserts metal

- Mô tả

- Đánh giá (0)

Mô tả

What are CBN Inserts?

CBN (Cubic Boron Nitride) inserts are ultra-hard cutting tools used for precision machining of hardened steels, cast irons, and superalloys. As the second-hardest material after diamond, CBN provides exceptional heat resistance and wear durability, making it ideal for high-speed, high-precision turning, milling, and boring operations where traditional carbide tools fail.

Materials of CBN Inserts

CBN Particles – Synthetic cubic boron nitride crystals (40%–90% concentration).

Ceramic Binder (TiN, Al₂O₃, TiC) – Enhances thermal stability and toughness.

Carbide Substrate – Tungsten carbide base for structural support (e.g., WC-Co).

Surface Treatments

TiN/TiAlN Coating – Reduces friction and extends tool life.

Mirror Polishing – Improves surface finish on machined parts.

Micro-Grain CBN – Refines edge sharpness for finishing cuts.

Specifications

Shape: Round (R), square (S), triangular (T), diamond (D).

Grain Size: Fine (0.5–2µm) for finishing / Coarse (5–10µm) for roughing.

CBN Content:

Low (40–50%) – For interrupted cuts (e.g., hardened steel milling).

High (80–90%) – For continuous turning (e.g., cast iron).

Nose Radius: 0.2mm–1.2mm (affects surface finish and tool strength).

Applications of CBN Inserts

Automotive – Machining hardened crankshafts, brake discs.

Aerospace – Turbine blades, landing gear components.

Oil & Gas – Drilling tool inserts for hard alloys.

Die/Mold Making – Precision finishing of tool steels (HRC 45+).

Medical Implants – Machining cobalt-chromium alloys.

Excellent Case: High-Speed Machining of Jet Engine Turbine Shafts

Scenario: A jet engine manufacturer needs to machine Inconel 718 turbine shafts (HRC 45) with tight tolerances (±0.01mm) and mirror finishes (Ra < 0.4µm). Traditional carbide tools wear out after 10 minutes.

Solution:

High-CBN (80%) inserts with TiAlN coating:

Shape: Round (R) with 0.4mm nose radius for fine finishing.

Cutting Parameters:

Speed: 250 m/min (vs. 80 m/min for carbide).

Feed: 0.05mm/rev.

Coolant: High-pressure through-tool cooling.

Results:

Tool Life: 120+ minutes (12× longer than carbide).

Surface Finish: Ra 0.3µm, eliminating manual polishing.

Cost Savings: $18,000/year per machine in reduced tool changes.

Đánh giá

Chưa có đánh giá nào.