Special Steel Threaded Inserts Black Oxide Nickel Plating Geomet Coating

Special Steel Threaded Inserts Black Oxide Nickel Plating Geomet Coating

- Mô tả

- Đánh giá (0)

Mô tả

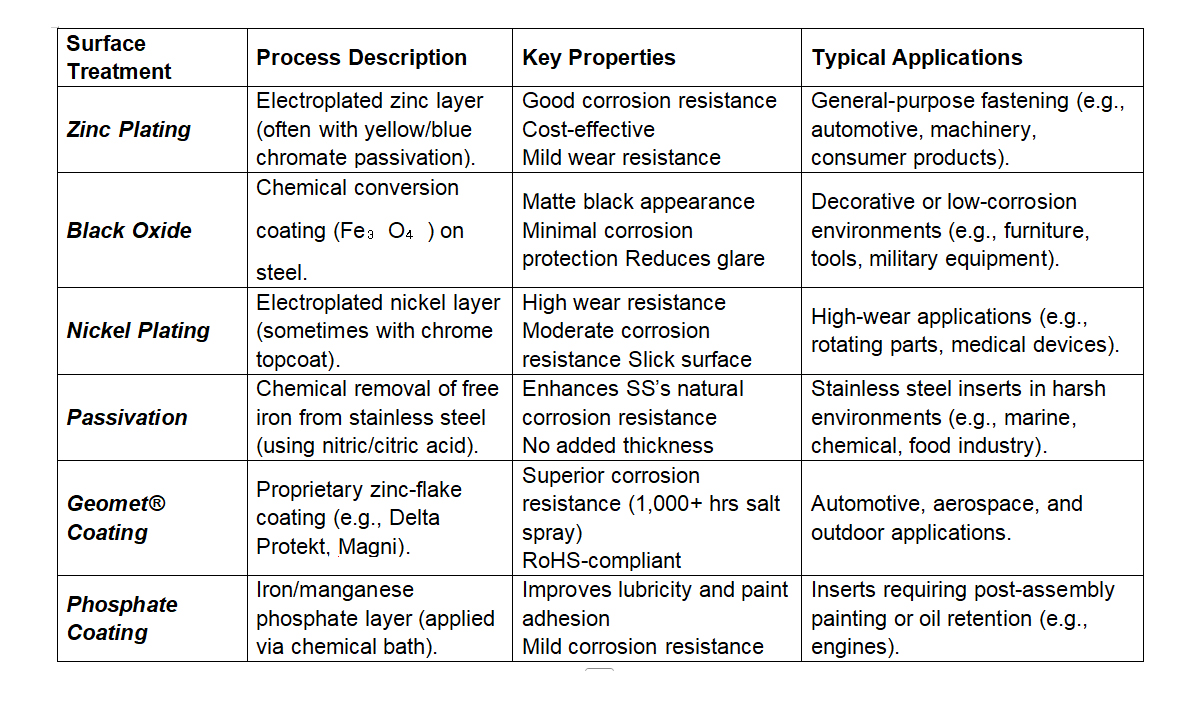

Steel Threaded Inserts – Surface Treatments & Specifications

Key Parameters for Specification of Steel Threaded Inserts

Corrosion Resistance :

Salt spray test hours (e.g., Zinc: 96–500 hrs; Geomet®: 1,000+ hrs).

Thickness :

Zinc plating: 5–25 µm; Nickel: 10–50 µm.

Hardness :

Nickel plating: ~500 HV; Black oxide: No significant change to base metal.

Compliance :

RoHS, REACH, ASTM B633 (zinc/nickel plating), AMS 2700 (passivation).

Material Pairing Guide

Carbon Steel Inserts : Use zinc/nickel plating or black oxide.

Stainless Steel Inserts : Opt for passivation or Geomet® coating.

Example :

M6 Stainless Steel Insert with passivation → Food processing equipment.

#10-24 Carbon Steel Insert with zinc plating → Automotive interior panels.

3 excellent cases of Steel Threaded Inserts

- Automotive: Engine Component Fastening

Insert Type : Carbon Steel, M8 x 1.25 (Metric Fine Thread)

Surface Treatment : Geomet® Coating (Zinc-Flake)

Why It Works :

Withstands 1,000+ hours salt spray resistance (critical for underhood parts).

Coating reduces friction during installation, preventing thread galling.

Application : Threaded inserts in aluminum engine blocks for spark plug mounts.

2. Electronics: Ruggedized Device Enclosures

Insert Type : Stainless Steel 304 , M3 x 0.5

Surface Treatment : Nickel Plating (5–10µm)

Why It Works :

EMI shielding due to conductive nickel layer.

Resists humidity and repeated disassembly (e.g., military radios).

Application : Threaded inserts in aluminum laptop casings for screw retention.

3. Medical: Sterilizable Equipment

Insert Type : Stainless Steel 316L , #6-32 UNC

Surface Treatment : Electropolished + Passivation

Why It Works :

Smooth surface minimizes bacterial adhesion (meets FDA/ISO 13485 ).

Survives autoclave sterilization (steam, chemicals).

Application : Inserts in surgical instrument handles.

Key Takeaways :

Corrosion Resistance : Geomet® for automotive, passivation for aerospace/medical.

Strength : Stainless steel (A286/316L) for extreme environments.

Aesthetics/Function : Black oxide for furniture, nickel for electronics.

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Đánh giá

Chưa có đánh giá nào.