Custom SUS 304 316 Square Bevel Washer Top Quality Square Taper Washer for Slot Section

Custom SUS 304 316 Square Bevel Washer Top Quality Square Taper Washer for Slot Section

- Açıklama

- Değerlendirmeler (0)

Açıklama

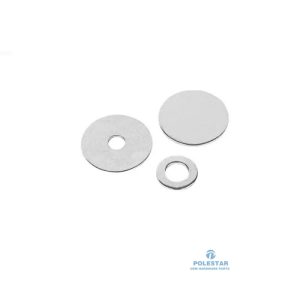

What is a Square Bevel Washer?

A Square Bevel Washer, also known as a square taper washer or inclined washer, is a specialized type of washer designed to sit between a nut or bolt head and an angled surface. Its key feature is that one face is beveled (sloped) to match the angle of the connected member, while the opposite face remains flat to provide a square, perpendicular bearing surface for the nut or bolt head. This ensures proper alignment, distributes the load evenly, and prevents loosening or bending due to an uneven connection.

Materials

Square bevel washers are made from durable materials to withstand structural loads and environmental factors.

Carbon Steel: The most common material, offering high strength for general structural applications.

Stainless Steel: Used for its excellent corrosion resistance, ideal for outdoor, marine, or chemically aggressive environments. Common grades are 304 and 316.

Hot-Dipped Galvanized Steel: Carbon steel washers with a thick zinc coating for superior rust protection, commonly used with galvanized structural steel.

Surface Finishes

The surface finish is applied to enhance durability and corrosion resistance.

Plain (Bare Steel): No coating, used for indoor applications or where painting will occur later.

Hot-Dip Galvanizing (HDG): A thick, durable zinc coating that provides excellent long-term protection against corrosion.

Zinc Plating: A thinner, electroplated zinc coating that provides a good level of rust resistance for standard applications.

Mechanical Galvanizing: A process that provides a zinc coating similar to hot-dip but without the risk of distortion for smaller parts.

Specifications

Key specifications define the size and angle of a square bevel washer to ensure a proper fit.

Hole Size: The inner diameter, which must match the bolt diameter (e.g., 1/2″, 5/8″, 3/4″).

Overall Square Size: The outer dimensions of the washer (e.g., 1-1/2″, 2″).

Thickness: The gauge or thickness of the steel.

Bevel Angle: The critical angle of the sloped face, which must match the angle of the structural member. Common angles are 30°, 45°, and 60°.

Application Fields

Square bevel washers are essential components in any structure involving sloped or angled connections.

Structural Steel Framing: Connecting beams and braces to columns, especially in seismic and wind bracing systems.

Pre-Engineered Metal Buildings (PEMB): Used extensively to connect angled roof and wall bracing to the main frame.

Bridge Construction: For bracing and cross-frame connections.

Transmission Towers and Communication Towers: Assembling the lattice structures where numerous angled members meet.

Heavy Equipment: Used in the frames and booms of machinery like cranes and excavators.

Excellent Case: Securing a Structural Steel Brace

During the construction of a new warehouse, steel crews needed to install diagonal braces between the vertical columns to provide stability against wind loads. The end of the brace was cut at a 45-degree angle to fit against the face of the column.

Without a bevel washer, bolting through this angled connection would have forced the bolt to bend and the nut to bear on a tiny, uneven point, creating a massive stress concentration and a weak, unsafe joint.

By using a hot-dip galvanized square bevel washer with a 45-degree angle, the installers created a perfect, full-contact fit. The washer’s beveled side sat flush against the sloped brace, while its flat side provided a stable, perpendicular base for the high-strength nut. This ensured the load was transferred evenly from the brace, through the washer, and into the bolt, resulting in a rigid, reliable, and code-compliant connection that guaranteed the long-term structural integrity of the building.

Değerlendirmeler

Henüz değerlendirme yapılmadı.