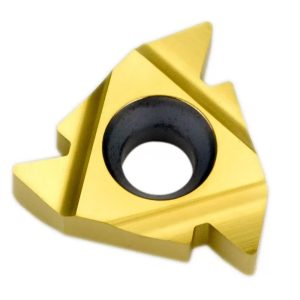

Rivet Threaded Inserts Flat Head Knurled Threaded Insert Rivet Nut M3 M4 M8 M10 M12

0 out of 5

Rivet Threaded Inserts Flat Head Knurled Threaded Insert Rivet Nut M3 M4 M8 M10 M12

Kategoriler: Threaded Inserts

Etiketler: brass rivet threaded inserts, brass threaded rivet nut inserts, m6 threaded inserts, pop rivet threaded inserts, Rivet Threaded Insert, Rivet Threaded Inserts, stainless steel rivet threaded inserts, stainless steel threaded rivet nut inserts, threaded insert, Threaded Insert Rivet Nut, threaded inserts, threaded rivet inserts for metal

- Açıklama

- Değerlendirmeler (0)

Açıklama

What Are Rivet Threaded Inserts?

Rivet threaded inserts are permanent fastening solutions that combine the functions of a rivet and a threaded insert. They are installed into pre-drilled holes in thin or soft materials (like sheet metal or plastic) to create durable, load-bearing threads. Unlike traditional inserts, they deform during installation to lock securely in place without requiring access to the backside of the material.

Rivet Threaded Inserts: Specifications

1. Material

Stainless Steel (304/316): Corrosion-resistant for marine/outdoor use

Aluminum (6061-T6): Lightweight for aerospace applications

Brass (CZ121): Non-sparking for explosive environments

Carbon Steel (Grade 5): Cost-effective for industrial equipment

2. Surface Treatment

Passivation (Stainless): Removes free iron, enhances corrosion resistance

Anodizing (Aluminum): Hard coating (Type III) for wear resistance

Zinc Plating (Carbon Steel): Basic corrosion protection

PTFE Coating: Dry lubricant for easy thread engagement

3. Common Specifications

Thread Sizes: #4-3/8″ UNC/M3-M12 metric

Grip Range: 0.5mm-6mm material thickness

Installation: Manual or pneumatic tool setting

Standards: NASM 33540, DIN 7337

4. Applications

Electronics: Thread reinforcement in aluminum device enclosures

Automotive: Plastic bumper mounting points

Aviation: Composite panel fastening in aircraft interiors

Medical: Lightweight equipment assemblies

Excellent Case: Electric Vehicle Battery Enclosure

Challenge:

An EV manufacturer needed to create reliable M6 threads in 2mm aluminum battery trays without welding (to avoid heat distortion). Traditional rivnuts failed under 50+ assembly cycles.

Solution:

Installed 316 stainless rivet inserts with knurled exterior:

Pull-Out Strength: 3,200N (vs 1,800N for standard rivnuts)

Conductivity: Maintained EMI shielding continuity

Installation Speed: 8 seconds per insert with pneumatic tool

Results:

Withstood 200+ battery pack service cycles

Reduced assembly defects by 95%

Achieved IP67 sealing with integrated O-ring option

Key Advantages

✔ Blind-Side Installation – No backside access required

✔ Material Versatility – Works in metals, plastics, composites

✔ Vibration Resistant – Knurling/locking features prevent rotation

Değerlendirmeler

Henüz değerlendirme yapılmadı.