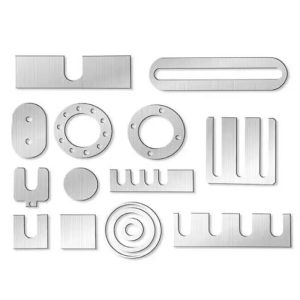

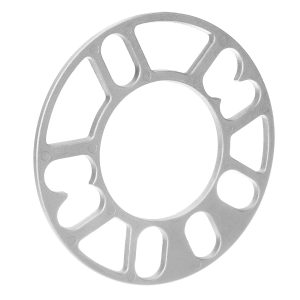

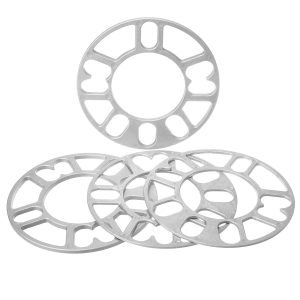

Aluminum Brake Rotor Spacer 6 Bolt Bicycle Disc Brake Rotor Spacer

0 out of 5

Aluminum Brake Rotor Spacer 6 Bolt Bicycle Disc Brake Rotor Spacer

Kategoriler: Metal Spacers

Etiketler: 1 aluminum spacer, 15mm metal spacer, 5mm metal spacer, aluminum spacer, aluminum spacer m3, aluminum spacer m8, bicycle disc brake rotor spacer, bike brake rotor spacer, bike disc brake rotor spacer, brake rotor spacer, CNC machined metal spacer, CNC Machined Metal Spacers, CNC machining metal spacer, CNC Machining Metal Spacers, CNC spacer, CNC spacers, Metal Spacer, Metal Spacers, motorcycle brake rotor spacer, rotor spacer

- Açıklama

- Değerlendirmeler (0)

Açıklama

What is a Brake Rotor Spacer?

A brake rotor spacer (also known as a disc rotor spacer) is a precision-engineered component designed to adjust the position of the brake rotor relative to the wheel hub or axle. It ensures proper alignment between the rotor and the brake caliper, preventing issues like uneven pad wear, brake drag, or vibration. These spacers are commonly used in automotive, motorsport, motorcycle, and industrial applications where precise rotor positioning is essential for optimal braking performance.

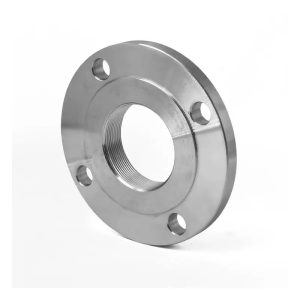

Materials Used for Brake Rotor Spacers

Brake rotor spacers must withstand high heat, pressure, and mechanical stress. The most commonly used materials include:

Aluminum Alloy – Lightweight and corrosion-resistant, ideal for performance vehicles and motorcycles. Offers good heat dissipation.

Stainless Steel – High strength and excellent rust resistance, making it suitable for harsh environments and heavy-duty applications.

Titanium – Extremely strong yet lightweight, often used in motorsports and aerospace for its durability and heat resistance.

Carbon Steel – Cost-effective and durable, commonly used in industrial machinery and commercial vehicles.

High-Temperature Plastics (PEEK, Polyamide) – Used in applications where weight savings are critical, such as bicycles or lightweight racing components.

Surface Treatments for Brake Rotor Spacers

To enhance durability and performance, brake rotor spacers often undergo specialized surface treatments:

Hard Anodizing (for Aluminum) – Increases wear resistance and thermal stability while preventing corrosion.

Zinc Plating (for Steel) – Protects against rust and extends lifespan in wet or corrosive environments.

Black Oxide Coating – Provides a corrosion-resistant finish while reducing light reflection (common in motorsports).

Ceramic Coating – Improves heat dissipation and reduces thermal stress on the rotor.

Passivation (for Stainless Steel) – Enhances corrosion resistance by removing free iron particles from the surface.

Specifications of Brake Rotor Spacers

Brake rotor spacers come in various dimensions and configurations depending on the application. Key specifications include:

Thickness – Typically ranges from 1mm to 15mm, with custom sizes available for specific setups.

Inner Diameter (ID) – Must match the hub or axle diameter precisely (e.g., 68mm for many Japanese cars, 72.6mm for BMWs).

Outer Diameter (OD) – Designed to fit within the rotor’s mounting surface without interfering with wheel installation.

Bolt Pattern Compatibility – Must align with the rotor’s stud or bolt holes (e.g., 5×114.3, 5×120, or 6×139.7).

Tolerances – High-performance spacers often have tight machining tolerances (±0.02mm to ±0.1mm) to ensure perfect fitment.

Applications of Brake Rotor Spacers

Brake rotor spacers are used in various industries, including:

Performance & Racing Cars – Correcting rotor alignment when installing big brake kits or aftermarket wheels.

Motorcycles & Superbikes – Adjusting rotor position for upgraded calipers or different wheel setups.

Off-Road & 4×4 Vehicles – Accommodating larger rotors or different hub configurations.

Industrial Machinery – Ensuring proper brake alignment in heavy equipment like cranes and forklifts.

Aerospace & Aviation – Precision spacing in aircraft braking systems.

Excellent Case: Track-Ready Porsche 911 GT3 Brake Upgrade

A professional racing team was preparing a Porsche 911 GT3 for a 24-hour endurance race. The car was fitted with a larger aftermarket brake kit, but the new rotors sat too close to the calipers, causing slight rubbing under hard braking.

Solution:

The team installed 3mm-thick, hard-anodized aluminum rotor spacers with a 72.6mm inner diameter to perfectly match the Porsche’s hub. The spacers shifted the rotor outward, ensuring proper clearance without affecting wheel balance.

Results:

✔ Eliminated Brake Drag – No more unwanted contact between pads and rotors.

✔ Improved Heat Dissipation – Proper spacing allowed better airflow, reducing brake fade during long stints.

✔ Enhanced Durability – The anodized coating resisted heat-induced corrosion, even after multiple race sessions.

✔ Consistent Performance – The spacers ensured even pad wear, maintaining peak braking efficiency throughout the race.

This case demonstrates how a small but critical component like a brake rotor spacer can make a huge difference in high-performance braking systems.

Conclusion

Brake rotor spacers may seem like minor components, but they play a vital role in ensuring proper brake alignment, performance, and safety. Whether in motorsports, street performance, or industrial applications, selecting the right material, thickness, and surface treatment is crucial for reliability and efficiency. Investing in high-quality spacers can prevent costly brake issues and maximize the lifespan of your braking system.

For optimal results, always choose precision-machined spacers from reputable manufacturers to ensure perfect fitment and long-term durability.

Değerlendirmeler

Henüz değerlendirme yapılmadı.