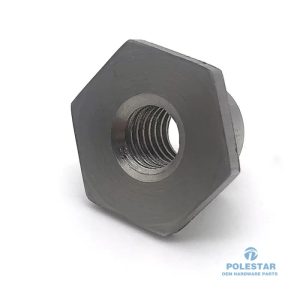

Precision Machined Lock Nuts Anti Loosening Design for Special Vibration Environments

0 out of 5

Precision Machined Lock Nuts Anti Loosening Design for Vibration Environments

หมวดหมู่: Machined Nuts

ป้ายกำกับ: 1 2 lock nuts, 1/4 lock nuts, 3 4 lock nuts, 5 8 lock nuts, all metal lock nuts, bearing lock nuts, brass lock nuts, car lock nuts, electrical lock nuts, flange lock nuts, lock nuts, lock nuts and washers, lock nuts vs lock washers, m10 lock nuts, m3 lock nuts, m5 lock nuts, m6 lock nuts, machined nut, Machined Nuts, nyloc lock nuts, nylon insert lock nuts, nylon lock nuts, ock nuts electrical, plastic lock nuts, security lock nuts, stainless lock nuts, steel lock nuts, wheel lock nuts, wheel lock nuts key, wheels lock nuts, wire lock nuts

- คำอธิบาย

- บทวิจารณ์ (0)

คำอธิบาย

What is a Lock Nut?

A lock nut (or locking nut) is a specialized fastener designed to resist loosening under vibration, torque, or dynamic loads. Unlike standard nuts, lock nuts incorporate features such as nylon inserts, deformed threads, or secondary locking mechanisms to maintain a secure hold on bolts. They are widely used in machinery, automotive, aerospace, and construction to prevent accidental disassembly.

Materials of Lock Nuts

Carbon Steel – Economical and strong, commonly zinc-plated for corrosion resistance.

Stainless Steel (304/316) – Excellent corrosion resistance, ideal for harsh environments.

Brass – Used in electrical/plumbing applications for its anti-sparking and anti-corrosive properties.

Alloy Steel (Grade 8/10) – High-strength for heavy-duty applications (e.g., automotive, industrial).

Nylon-Insert (Polyamide) – A plastic insert provides friction-based locking (e.g., “nyloc” nuts).

Surface Treatments

Zinc Plating – Standard corrosion protection for steel nuts.

Hot-Dip Galvanizing – Thick zinc coating for outdoor/industrial use.

Black Oxide – Improves wear resistance and reduces glare.

Dacromet Coating – High corrosion resistance without hydrogen embrittlement.

Passivation (Stainless Steel) – Removes free iron particles to enhance rust resistance.

Specifications

Thread Standards: Metric (M4–M30), UNC/UNF (e.g., 1/4″-20, 3/8″-16).

Locking Mechanisms:

Nylon insert (e.g., Nyloc nut).

Metal crimp (e.g., Keps nut with integrated washer).

Double nut (jam nut technique).

Serrated flange (prevents rotation through teeth).

Strength Grades:

Metric: Class 8, 10, 12.

SAE: Grade 2, 5, 8.

Applications

Automotive – Wheel hubs, engine mounts, suspension systems.

Aerospace – Critical assemblies requiring vibration resistance.

Industrial Machinery – Conveyors, presses, and rotating equipment.

Construction – Scaffolding, steel structures, and bridges.

Electronics – Securing PCBs or sensitive components.

Excellent Case: High-Speed Train Wheel Assembly

Scenario: A high-speed train’s wheel axles experience extreme vibrations and dynamic loads, risking bolt loosening over time.

Solution:

Engineers use all-metal lock nuts (e.g., prevailing torque nuts) with serrated flanges.

Material: Grade 10 alloy steel with Dacromet coating for corrosion resistance.

Mechanism: The nut’s deformed threads create constant friction, resisting rotation.

Benefits:

Eliminates the need for secondary adhesives (e.g., Loctite).

Withstands vibrations at speeds exceeding 300 km/h.

Long-term reliability with minimal maintenance.

Result: The lock nuts ensure the wheel assemblies remain securely fastened throughout the train’s operational life, preventing catastrophic failures and enhancing passenger safety.

รีวิว

ยังไม่มีบทวิจารณ์