Custom Key Locking Inserts Carbon Steel Stainless Steel for Repair Thread

0 out of 5

Custom Key Locking Inserts Carbon Steel Stainless Steel for Repair Thread

Categoria: Threaded Inserts

Etiquetas: 3/8 threaded inserts, key locked inserts, key locked threaded inserts, key locking inserts, key locking threaded inserts, keysert key locking inserts, M12 threaded inserts, m2 threaded inserts, m5 threaded inserts, stainless steel threaded inserts, threaded insert, threaded inserts, threaded inserts metal, threaded inserts steel

- Descrição

- Avaliações (0)

Descrição

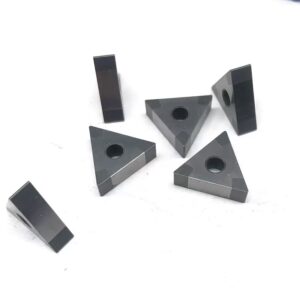

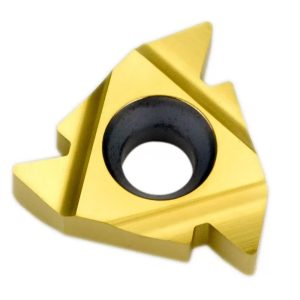

What Are Key Locking Inserts?

Key Locking Inserts (also called key-locking threaded inserts or key-lock bushings) are high-strength threaded fasteners designed to provide permanent, vibration-resistant threads in soft or brittle materials (e.g., aluminum, plastic, or composites). They feature external locking keys that dig into the host material when installed, preventing rotation or loosening under dynamic loads.

Specifications of Key Locking Inserts

1. Material

Stainless Steel (304, 316 – corrosion-resistant for harsh environments).

Carbon Steel (Grade 8 – high strength, often zinc-plated).

Aluminum (lightweight applications).

Brass (electrical/thermal conductivity, corrosion resistance).

2. Surface Treatment

Zinc Plating (anti-corrosion, general-purpose use).

Black Oxide (wear resistance, mild corrosion protection).

Passivation (for stainless steel, enhances corrosion resistance).

Nickel Plating (high corrosion & chemical resistance).

3. Common Specifications

Thread Sizes: M3–M24 (metric), #4–1″ (UNC/UNF).

Installation Types:

Press-in (for plastics/soft metals).

Threaded (pre-threaded for easier installation).

Key-Lock Design (external barbs/keys for anti-rotation).

Load Capacity: Up to 5x higher pull-out strength vs. standard inserts.

4. Applications

Automotive & Aerospace (engine mounts, vibration-prone assemblies).

Industrial Machinery (motor housings, gearbox connections).

Electronics (PCB mounts in high-shock environments).

Marine & Defense (saltwater-resistant fastening).

Plastic/Composite Parts (reinforcing threads in weak materials).

Excellent Case: Servo Motor Mounting in Robotic Arm

Challenge

A robotics manufacturer needed a vibration-proof, high-strength threaded solution to secure servo motors in an industrial robotic arm. Traditional screws kept loosening due to constant movement/shock, causing misalignment and downtime.

Solution

Key Locking Inserts (Stainless Steel, M6 size) were installed into the aluminum motor housing.

Installation Process:

A precise hole was drilled/tapped in the motor mount.

The insert was threaded in and pressed, causing its external locking keys to bite into the aluminum.

A high-tensile bolt secured the motor, with Loctite® for extra retention.

Results

✔ Zero Loosening – Withstood 50,000+ movement cycles without failure.

✔ Higher Torque Capacity – Insert threads held 3x more torque vs. direct aluminum threading.

✔ Easy Maintenance – Bolts could be removed/replaced without damaging the threads.

Industry

Industrial Automation (6-Axis Robotic Arm)

Why Use Key Locking Inserts for Motors?

✅ Vibration Resistance – Keys prevent rotation under shock/dynamic loads.

✅ Thread Reinforcement – Protects soft metals/plastics from stripping.

✅ Corrosion Resistance – Stainless steel options for harsh environments.

✅ Long-Term Reliability – Outlasts standard threaded solutions.

Avaliações

Ainda não existem avaliações.