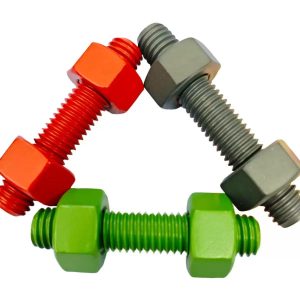

Internally Threaded Studs for Welding Assembly Heavy Duty Fastener Components

Internally Threaded Studs for Welding Assembly Heavy Duty Fastener Components

- Descrição

- Avaliações (0)

Descrição

What are Internally Threaded Studs?

Internally threaded studs are cylindrical fasteners with internal threading (female threads) on one or both ends, allowing bolts or other threaded components to be securely attached. They are commonly used in assemblies where a bolt needs to be fastened into a blind hole or where disassembly and reassembly are frequent.

Materials

Internally threaded studs are manufactured from various materials to meet different mechanical and environmental requirements:

Carbon Steel (Grade 4.8, 8.8, 10.9) – High strength, cost-effective

Stainless Steel (AISI 304, 316) – Corrosion-resistant for harsh environments

Alloy Steel (AISI 4140, 4340) – Heat-treated for extreme durability

Brass – Non-corrosive, electrically conductive

Titanium – Lightweight, high strength-to-weight ratio, aerospace-grade

Surface Treatments

To enhance performance and longevity, internally threaded studs may undergo:

Zinc Plating (Yellow/White) – Prevents rust and improves wear resistance

Hot-Dip Galvanizing – Heavy-duty corrosion protection

Black Oxide Coating – Reduces glare and provides mild rust resistance

Nickel Plating – Improves corrosion resistance and aesthetic finish

Passivation (for stainless steel) – Enhances oxide layer for better corrosion protection

Specifications

Internally threaded studs come in a variety of sizes and configurations:

Thread Size (Metric/Imperial): M3 to M30, or #4 to 1″

Thread Pitch: Fine or coarse threads depending on application

Length: 10mm to 300mm (or custom lengths)

Thread Depth: Full-length or partial threading

Tolerance Class: 6H (standard) or tighter for precision applications

Applications

Internally threaded studs are widely used in industries requiring secure fastening with easy disassembly:

✔ Automotive – Engine mounts, exhaust systems

✔ Aerospace – Structural assemblies, avionics mounting

✔ Machinery & Heavy Equipment – Hydraulic systems, gearbox assemblies

✔ Electronics – PCB mounting, enclosure fastening

✔ Construction & Infrastructure – Steel frame connections, anchoring systems

Excellent Case: High-Precision CNC Machine Tool Assembly

Industry: Industrial Machinery

Challenge: A CNC machine manufacturer needed a secure yet adjustable fastening system for precision tooling components that required frequent calibration and replacement. Traditional bolts in tapped holes caused thread wear over time, leading to misalignment.

Solution: The engineers used hardened alloy steel internally threaded studs (Grade 10.9) with a black oxide finish. These studs were press-fitted into critical mounting points, allowing tooling components to be bolted in and adjusted without damaging the base material.

Result:

Extended service life – Reduced thread wear by eliminating direct bolt-to-base material contact

Faster maintenance – Tools could be swapped without re-tapping threads

Improved precision – Consistent alignment due to secure stud anchoring

Avaliações

Ainda não existem avaliações.