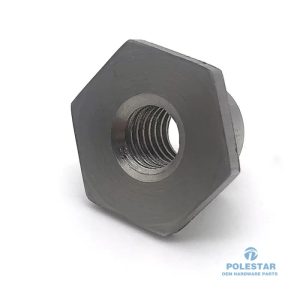

Heavy Duty Hex Slotted Castle Nuts Stainless Steel Crown Nuts DIN 935

Heavy Duty Hex Slotted Castle Nuts Stainless Steel Crown Nuts DIN 935

- Descrição

- Avaliações (0)

Descrição

What Are Castle Nuts?

Castle nuts, also known as castellated nuts or slotted nuts, are a specialized type of fastener designed to provide secure, vibration-resistant locking when used with cotter pins or wire. These nuts feature a unique crown-like top with notched “castellations” that align with holes in mating bolts or studs, allowing a cotter pin to be inserted for positive mechanical locking.

Unlike standard nuts that rely solely on friction, castle nuts provide a fail-safe locking mechanism that prevents loosening even under extreme vibration or dynamic loads. This makes them ideal for critical applications where fastener failure could have serious consequences, such as in automotive steering systems, aircraft assemblies, and heavy machinery.

Materials for Castle Nuts

Castle nuts are manufactured in various materials to meet different strength and environmental requirements:

Carbon Steel (Grade 5/8) – The most common choice, offering high strength and durability for general industrial use

Stainless Steel (304/316) – Provides excellent corrosion resistance for marine, chemical, and food processing applications

Alloy Steel – Used in high-stress applications requiring superior tensile strength

Brass – Selected for electrical applications and corrosive environments where non-sparking properties are needed

Aluminum – Lightweight option for aerospace and automotive applications where weight reduction is critical

Surface Finishes for Castle Nuts

Various surface treatments enhance performance and longevity:

Zinc Plating – Basic corrosion protection with a shiny silver appearance

Hot-Dip Galvanizing – Heavy-duty coating for outdoor and industrial environments

Black Oxide – Provides mild corrosion resistance and reduces light reflection

Cadmium Plating – High-performance coating for aerospace applications (being phased out due to environmental concerns)

Nickel Plating – Offers both corrosion resistance and decorative appeal

Phosphate Coating – Improves lubricity and corrosion resistance in automotive applications

Specifications of Castle Nuts

Thread Sizes: Range from #10-32 to 1-1/2″ in imperial sizes, and M5 to M36 in metric

Height: Typically taller than standard nuts to accommodate the castellated design

Standards: Complies with DIN 935, ISO 7035, MS17825, and AN/MS standards

Slot Width: Designed to accommodate standard cotter pin sizes (1/16″ to 1/4″)

Temperature Range: Varies by material, generally -50°C to +300°C for most steel variants

Applications of Castle Nuts

Castle nuts are essential in industries where safety-critical fastening is required:

Automotive: Steering linkages, wheel bearings, suspension components

Aerospace: Flight control systems, landing gear assemblies, engine mounts

Heavy Equipment: Excavator joints, crane assemblies, agricultural machinery

Military/Defense: Weapon mounts, vehicle armor, tactical equipment

Marine: Rudder assemblies, propeller shafts, deck hardware

Industrial Machinery: Presses, conveyor systems, power transmission components

Excellent Case: Aircraft Landing Gear Assembly

Challenge

A major aircraft manufacturer needed to ensure absolute reliability of landing gear fasteners, where any loosening could lead to catastrophic failure. Traditional locking methods had proven inadequate under the extreme vibration and shock loads experienced during takeoff and landing.

Solution

The engineering team specified high-strength alloy steel castle nuts with cadmium plating for all critical landing gear pivot points. Each nut was precisely torqued and secured with stainless steel cotter pins, with redundant safety wiring where needed.

Results

Zero Failures: No reported instances of loosening after 10,000+ flight cycles

Enhanced Safety: Positive mechanical locking provided fail-safe security

Maintenance Efficiency: Visual inspection of cotter pins allowed quick verification of fastener integrity

Regulatory Compliance: Met all FAA and EASA requirements for flight-critical fasteners

This application demonstrates how castle nuts provide unmatched reliability in situations where human lives depend on fastener integrity.

Conclusion

Castle nuts represent the gold standard for secure fastening in high-vibration, safety-critical applications. Their unique castellated design combined with positive cotter pin locking creates a mechanical connection that simply cannot be duplicated by friction-based alternatives. From keeping wheels on vehicles to ensuring aircraft remain safely airborne, castle nuts play a vital role in modern engineering.

The versatility of materials and finishes allows castle nuts to perform in virtually any environment, while standardized dimensions ensure compatibility with existing fastener systems. When absolute fastening security is required, engineers continue to trust this time-proven solution that has safeguarded mechanical assemblies for over a century.

Avaliações

Ainda não existem avaliações.