Hex Tapped Brass Insert M5 M6 Brass Inserts for Plastic Mouldings

Hex Tapped Brass Insert M5 M6 Brass Inserts for Plastic Mouldings

- Descrição

- Avaliações (0)

Descrição

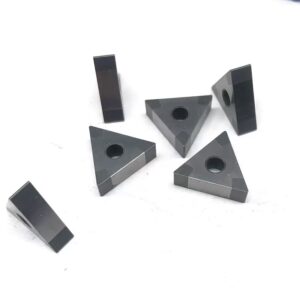

What is a Hex Tapped Brass Insert?

A Hex Tapped Brass Insert is a threaded brass fastener designed to be embedded into a softer material (such as plastic, wood, or composite) to provide a durable, wear-resistant threaded hole. It features an external hexagon for easy installation using a standard wrench or socket, and an internal thread to accept screws or bolts. These inserts are widely used in applications requiring repeated assembly and disassembly while maintaining thread integrity.

Specifications of Hex Tapped Brass Insert

Material:

Brass (C36000 or equivalent) – Offers excellent machinability, corrosion resistance, and electrical conductivity.

Alternative: Lead-free brass for environmentally sensitive applications.

Surface Treatment:

Natural Brass (Untreated) – Standard finish for general use.

Nickel Plating – Enhances corrosion resistance and provides a shiny appearance.

Zinc Plating – Improves rust resistance in harsh environments.

Common Sizes & Thread Types:

Internal Threads: Metric (M2, M3, M4, etc.) or Imperial (#4-40, #6-32, #8-32, etc.).

External Hex Size: Typically matches standard wrench sizes (e.g., 5mm, 6mm, 8mm).

Length: Varies from 6mm to 20mm depending on application.

Key Features:

High thread strength for repeated use.

Hex drive prevents rotation during installation.

Self-tapping or press-fit designs available.

Applications of Hex Tapped Brass Inserts

Electronics: Securing PCBs, housings, or heat sinks.

Furniture: Reinforcing joints in wooden or composite materials.

Automotive: Fastening interior panels or plastic components.

Industrial Equipment: Providing durable threads in soft metal or polymer parts.

Consumer Goods: Toys, appliances, and DIY products requiring reliable threads.

Plastic Mouldings: Embedding into injection-molded or thermoformed plastic parts to create strong, reusable threaded anchors for assembly.

Excellent Case: Reinforcing Plastic Mouldings in Automotive Components

Scenario: An automotive manufacturer produces a plastic intake manifold that requires metal brackets to be securely attached. The original plastic threads degrade over time due to thermal cycling and vibration, leading to loosening and part failure.

Solution:

Insert Integration in Moulding Process:

During Injection Molding: Hex tapped brass inserts (e.g., M6 internal thread, 10mm hex) are placed into the mold cavity before plastic is injected. The molten plastic flows around the insert, locking it in place upon cooling.

Post-Molding Press-Fit: For thermoformed plastics, inserts are pressed into pre-machined holes using a thermal or ultrasonic insertion tool.

Result:

The brass insert provides a high-strength, heat-resistant threaded anchor that withstands engine heat and vibration.

The hex external shape prevents rotation during bracket installation or maintenance.

Eliminates thread stripping, reducing warranty claims and improving product lifespan.

Why It’s Ideal for Plastic Mouldings:

Brass’s thermal expansion is compatible with many plastics, reducing stress cracks.

Hex drive ensures insert stability during molding and screw tightening.

Cost-effective compared to overmolded metal threads or welded solutions.

Avaliações

Ainda não existem avaliações.