Stainless Steel DIN 6796 Wave Spring Washer for Industrial Machinery

Stainless steel DIN 6796 wave spring washer for industrial machinery

- 描述

- 用户评价 (0)

描述

Stainless Steel DIN 6796 Wave Spring Washer for Industrial Machinery

Wave Tooth Washer

The Wave Tooth Washer (also known as a wave spring washer or tooth lock washer ) is a type of fastener designed to prevent loosening due to vibration, thermal expansion, or dynamic loads. Its unique wave-like or serrated structure provides tension and maintains clamping force in bolted joints.

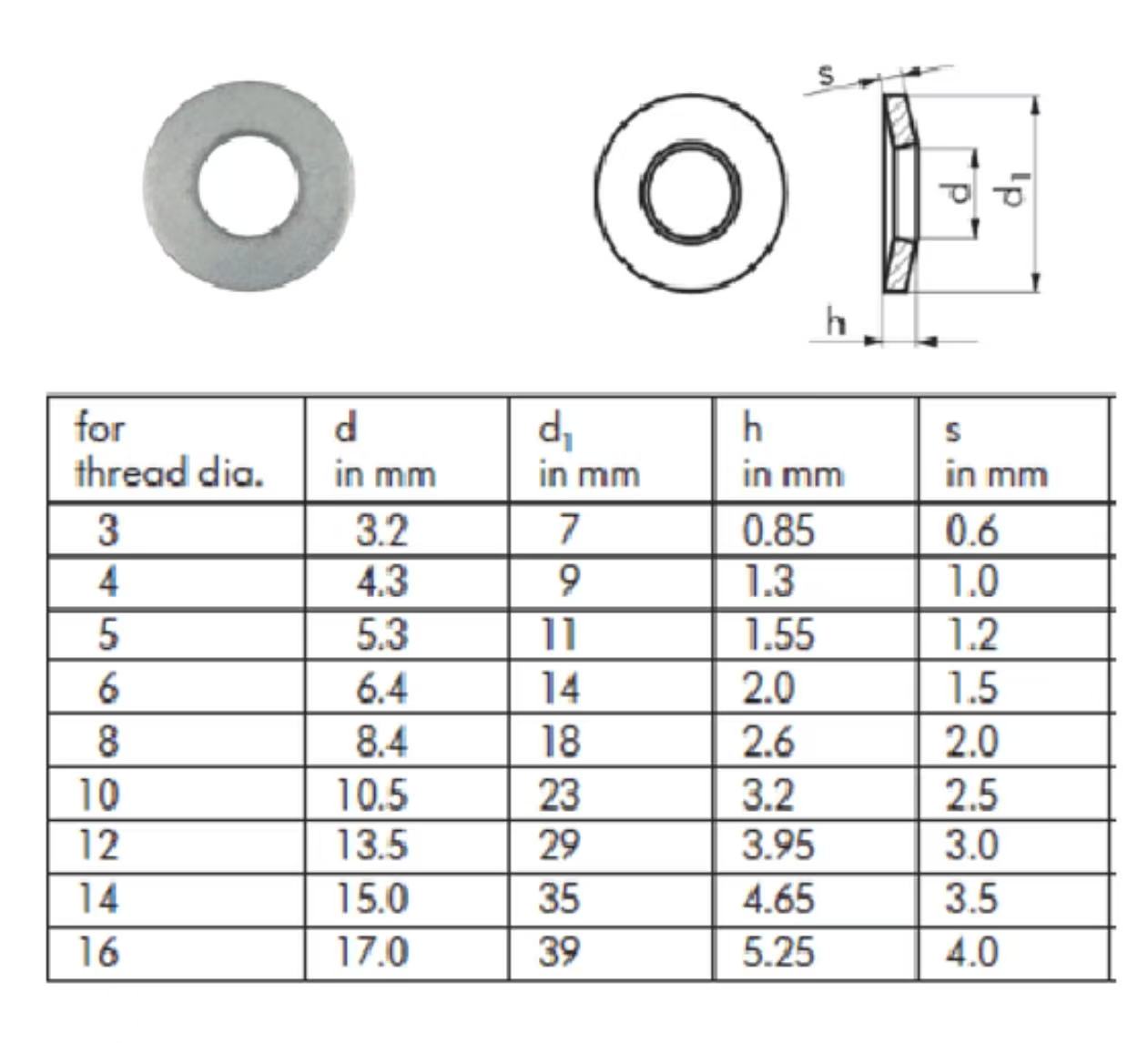

Specifications & Dimensions

Material: Typically made from carbon steel (Grade 8, 10, or 12.9), stainless steel (A2/AISI 304 or A4/AISI 316), or alloy steel .

Surface Treatment: Zinc-plated, black oxide, or phosphated for corrosion resistance.

Standards: DIN 6796, ISO 8752, ANSI B18.21.1.

Common Sizes (Diameter x Thickness):

M3 to M24 (metric)

#4 to 1″ (imperial)

Wave Height: Varies between 0.2mm to 2mm depending on size.

Load Capacity: Can handle medium to high preload forces , depending on material grade.

Primary Applications

✔ Prevents Loosening – Used in automotive, aerospace, machinery, and electronics to secure bolts/nuts.

✔ Compensation for Thermal Expansion – Ideal for engines, turbines, and high-temperature equipment.

✔ Vibration Damping – Effective in industrial motors, pumps, and heavy machinery .

✔ Space-Saving Design – Thinner than traditional spring washers, useful in compact assemblies.

Notable Use Cases (Excellent Examples)

Automotive Industry – Used in engine mounts, transmission systems, and suspension components to prevent bolt loosening under vibration.

Aerospace & Defense – Applied in aircraft engines, landing gear, and satellite assemblies for reliable fastening under extreme conditions.

Industrial Machinery – Secures pump shafts, conveyor systems, and hydraulic fittings in factories.

Electronics & Robotics – Found in servo motors, robotic arms, and PCB mounts due to their low-profile design.

Renewable Energy – Used in wind turbine blade fasteners and solar panel mounting systems for long-term stability.

Advantages Over Standard Washers

Better grip due to teeth/wave design.

Maintains tension even under dynamic loads.

Reduces wear on mating surfaces compared to flat washers.

Why Choose Polestar Metal?

Suzhou Polestar Metal Products is a specialized manufacturer in custom hardware solutions, excelling in precision CNC machining and non-standard fastener production. With extensive experience collaborating on design projects for diverse clients, our in-depth material expertise and advanced process control enable us to deliver high-quality, cost-effective products. Recognized and trusted by numerous customers, we remain committed to continuous innovation and the development of cutting-edge solutions.

评价

目前还没有评价