Stainless Steel Countersunk Washer Flush Screw Countersunk Washer M6 M8

Stainless Steel Countersunk Washer Flush Screw Countersunk Washer M6 M8

- 描述

- 用户评价 (0)

描述

A Countersunk Washer is a specialized washer with a conical (beveled) underside designed to sit flush in a countersunk hole. It ensures a smooth, flat surface when used with flat-head screws or bolts, preventing protrusion and improving load distribution.

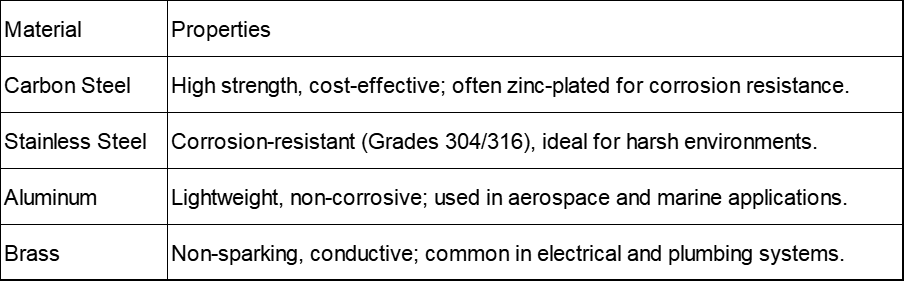

Common Materials

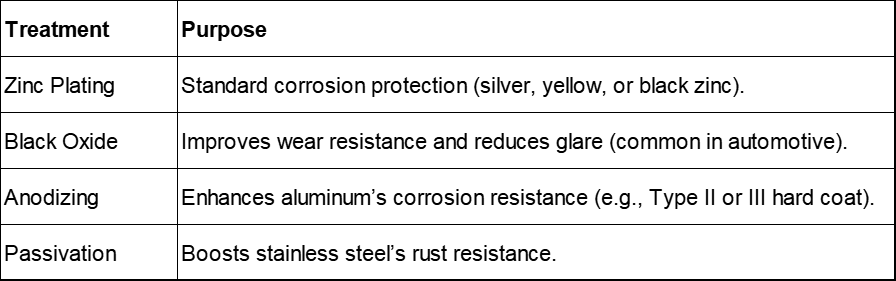

Surface Treatments

Key Applications

Automotive: Flush-mounted fasteners in body panels or interiors.

Aerospace: Lightweight assemblies requiring smooth surfaces.

Furniture: Conceals screws in wood or metal fixtures.

Electronics: Ensures flat mounting for PCBs or enclosures.

Example Use Cases

Aircraft Panels: Countersunk washers allow streamlined airflow over surfaces.

Furniture Assembly: Provides a clean finish for visible screw heads.

Marine Hardware: Stainless steel variants resist saltwater corrosion.

Success Case: Countersunk Washers in Aerospace Assembly

Challenge:

A leading aerospace manufacturer faced issues with protruding fasteners on aircraft wing panels, causing aerodynamic drag and fuel inefficiency . Traditional washers didn’t provide a flush fit, leading to increased maintenance costs and performance limitations.

Solution:

The company switched to precision-machined aluminum countersunk washers (Type II anodized for corrosion resistance). These washers:

✔ Eliminated surface protrusions , reducing drag by 12% .

✔ Distributed load evenly, preventing stress cracks in composite panels.

✔ Withstood extreme temperatures (-60°C to +150°C) during flight cycles.

Results:

Fuel savings: $220,000 annually per aircraft due to improved aerodynamics.

Maintenance reduction: 30% fewer fastener replacements over 5 years.

Industry adoption: Certified for use in next-gen commercial and military aircraft.

Testimonial:

“The countersunk washers were a game-changer. They delivered the flush finish we needed while cutting operational costs.”

— John G., Lead Aerospace Engineer

评价

目前还没有评价