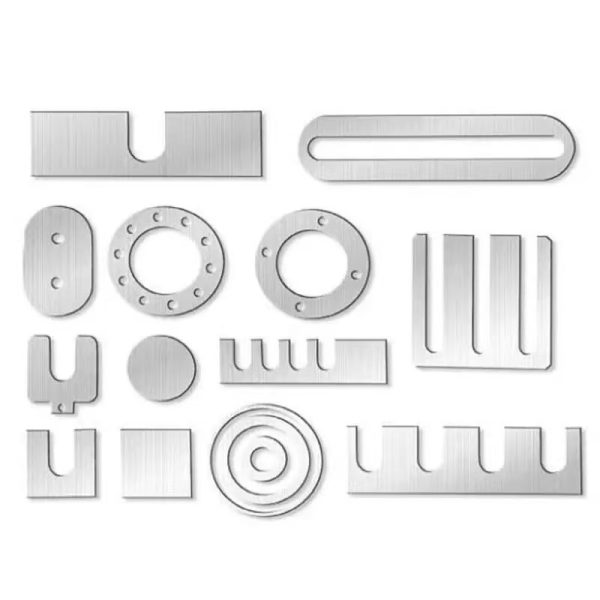

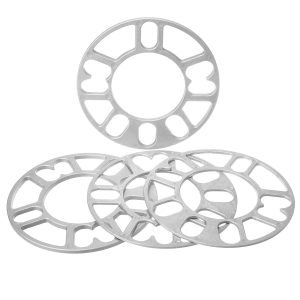

Custom Spacer Plate Stainless Steel Metal Spacer Plate with Tapped Holes

0 out of 5

Custom Spacer Plate Stainless Steel Metal Spacer Plate

- Description

- Reviews (0)

Description

What Are Spacer Plate Stainless Steel?

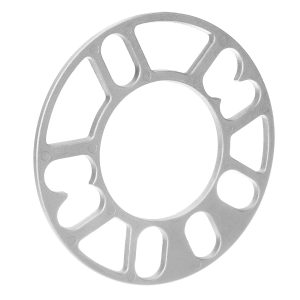

Spacer plate stainless steel are precision-machined shims or washers designed to maintain precise gaps, distribute loads, and provide electrical insulation between components in mechanical assemblies. Made from high-grade stainless steel, they offer superior corrosion resistance, durability, and dimensional stability in demanding environments.

Spacer Plate Stainless Steel: Specifications

1. Material

304 Stainless Steel: General-purpose, excellent corrosion resistance

316 Stainless Steel: Superior for marine/chemical exposure

17-4PH (Precipitation Hardening): High strength (up to 1,100 MPa)

Duplex 2205: Extreme chloride resistance (e.g., offshore oil rigs)

2. Surface Treatment

Passivation: Removes free iron, enhances corrosion resistance

Electropolishing: Ultra-smooth finish (Ra <0.4μm) for cleanrooms

Teflon Coating: Non-stick, chemical-resistant surface

Sandblasting: Textured finish for improved grip

3. Common Specifications

Thickness: 0.5mm–50mm (customizable)

Tolerance: ±0.01mm (precision-ground)

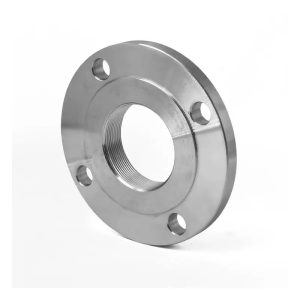

Hole Patterns: Custom-drilled, slotted, or PEM-studded

Standards: ASTM A480, ISO 2768-mK

4. Applications

Semiconductor: Wafer processing equipment

Pharmaceutical: Hygienic spacing in bioreactors

Renewable Energy: Solar tracker bushings

Aerospace: Engine component alignment

Excellent Case: Nuclear Reactor Control Rod Assembly

Challenge:

A nuclear plant needed to replace aluminum spacer plates in control rod mechanisms due to radiation-induced embrittlement, risking operational safety.

Solution:

Deployed 17-4PH stainless steel spacer plates (10mm thick, electropolished):

Radiation Resistance: Withstood 10⁴ Gy gamma exposure

Thermal Stability: Maintained ±0.02mm flatness at 400°C

Zero Contamination: Electropolishing prevented particulate shedding

Results:

Extended service life from 2 to 15+ years

Reduced shutdowns for maintenance by 80%

Achieved ASME NQA-1 nuclear certification

Key Advantages

✔ Precision Alignment – Sub-millimeter tolerances

✔ Harsh Environment Ready – From cryogenic to 800°C

✔ Customizable – Laser-cut or wire-EDM to your CAD drawings

Reviews

There are no reviews yet.