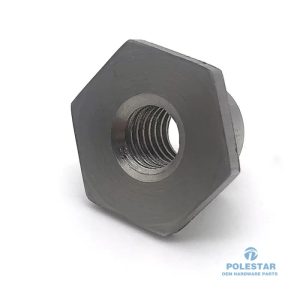

Custom Self Clinching Flush Nuts Stainless Steel 304 M2 M2.5 M3 M4 M5

Custom Self Clinching Flush Nuts Stainless Steel 304 M2 M2.5 M3 M4 M5

- Description

- Reviews (0)

Description

Self clinching flush nuts are specialized threaded fasteners designed to be permanently pressed into thin sheet metal, creating a flush (smooth) surface on one side. Unlike standard nuts, they feature a knurled or ribbed shank that displaces metal when installed, locking securely in place. Once pressed in, they provide a strong, reusable threaded insert that resists pull-out, rotation, and loosening under vibration.

Key Features of Self Clinching Flush Nuts

1. Materials

Carbon Steel – Economical, general-purpose use

Stainless Steel (304/316) – Corrosion-resistant for harsh environments

Aluminum – Lightweight, ideal for aerospace & electronics

Brass – Non-magnetic, excellent for electrical applications

2. Surface Finishes

Zinc Plating – Basic rust protection (common for carbon steel)

Nickel Plating – Enhanced durability & corrosion resistance

Black Oxide – Aesthetic & mild corrosion resistance

Passivation (Stainless Steel) – Maximizes corrosion resistance

3. Common Sizes & Thread Types

Metric Threads: M2, M3, M4, M5, M6

Imperial Threads: #4-40, #6-32, #8-32, #10-24, 1/4-20

Flush Head Design – Ensures a smooth surface after installation

Hex or Round Body – Compatible with different installation tools

4. Applications

Electronics Enclosures – Securing PCBs or control panels

Automotive Panels – Fastening dashboards, ECU housings

Aerospace & Defense – Lightweight, vibration-resistant assemblies

Medical Equipment – Secure, clean fastening for devices

Industrial Machinery – Panels requiring frequent access

Excellent Case: Medical Device Enclosure Assembly

Problem:

A medical device manufacturer needed a secure, flush-mounting solution for an ultrasound machine’s control panel. Traditional nuts and bolts protruded, creating discomfort for operators and potential hygiene issues. Welding was not an option due to material sensitivity.

Solution:

Stainless steel (316) self clinching flush nuts (M4 threads, passivated finish) were pressed into the aluminum enclosure.

The control panel was then fastened with machine screws, ensuring a smooth, snag-free surface.

The installation required no welding or secondary operations, speeding up production.

Benefits:

✔ Flush Surface – No protrusions for easy cleaning & operator safety

✔ Corrosion-Resistant – Withstands sterilization chemicals

✔ Vibration-Proof – Critical for medical equipment reliability

✔ Fast Installation – Reduced assembly time vs. welding or tapping

Conclusion

Self clinching flush nuts provide a clean, permanent, and vibration-resistant threaded solution for sheet metal applications where a smooth surface is critical. They are widely used in medical, automotive, aerospace, and electronics industries for their strength, reliability, and ease of installation.

Reviews

There are no reviews yet.