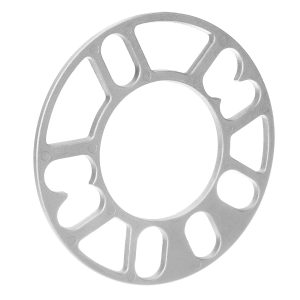

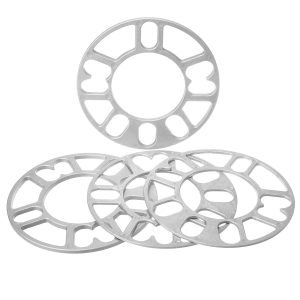

Custom Metal Spacers for Bolts M6 Stainless Steel Bolt Spacer

0 out of 5

Custom Metal Spacers for Bolts Stainless Steel Bolt Spacer

- Description

- Reviews (0)

Description

Metal spacers for bolts (also called standoffs or bushings) are cylindrical or hexagonal components used to create precise gaps between fastened parts. They maintain alignment, distribute load, prevent galvanic corrosion, and allow airflow/cable routing in assemblies.

Specifications of Metal Spacers for Bolts

1. Material

Aluminum (6061-T6): Lightweight, corrosion-resistant for electronics.

Stainless Steel (304/316): High strength, ideal for harsh environments.

Brass (CZ121): Anti-galling, used in electrical/plumbing systems.

Carbon Steel (Grade 8.8): Cost-effective for industrial machinery.

2. Surface Treatment

Anodized (Aluminum): Color-coded, enhanced wear resistance.

Passivated (Stainless Steel): Removes iron particles, improves corrosion resistance.

Nickel-Plated (Brass/Carbon Steel): Decorative and anti-rust.

Zinc-Coated (Carbon Steel): Budget-friendly corrosion protection.

3. Common Specifications

Inner/Outer Diameter: 2mm–50mm (customizable).

Length: 5mm–200mm (standard), longer on request.

Thread Types: Metric (M3–M12), UNC/UNF, or unthreaded (sleeve type).

Standards: DIN 988, ISO 9001, RoHS-compliant.

4. Applications

Electronics: PCB mounting, server racks, heat sink spacing.

Automotive: Battery trays, sensor brackets, engine covers.

Aerospace: Avionics panels, lightweight structural spacing.

Construction: Solar panel frames, HVAC duct supports.

Excellent Case: Vibration Isolation in Industrial Robotics

Challenge:

A robotic arm manufacturer faced premature bearing failures due to metal-on-metal contact between bolts and aluminum joints, causing vibration-induced wear.

Solution:

Installed anodized aluminum spacers (M8×20mm) between bolts and joints.

Key Benefits:

Vibration Damping: Reduced stress on bearings by 60%.

Corrosion Prevention: Anodizing prevented galvanic reaction with steel bolts.

Easy Maintenance: Modular design allowed quick part replacement.

Result:

Extended bearing lifespan by 3x and cut downtime by 35%.

Key Advantages Summary

✔ Precision Alignment – Ensures consistent gaps in assemblies.

✔ Versatility – Available in conductive/non-conductive materials.

✔ Cost-Efficient – Eliminates machining custom gaps.

Need spacers for your project? Contact us for samples! 🛠️

Reviews

There are no reviews yet.