Low Thermal Expansion Titanium Stainless Steel Spacers For Glass Facade Assembly in High-Tech Architecture

Low Thermal Expansion Titanium Stainless Steel Spacers For Glass Facade Assembly in High-Tech Architecture

- 描述

- 用户评价 (0)

描述

Low Thermal Expansion Titanium Stainless Steel Spacers For Glass Facade Assembly in High-Tech Architecture

Standoff Types: Threaded, unthreaded, male-female, swivel, and snap-in variants.

Finishes: Polished, brushed, anodized, powder-coated, or plated (e.g., nickel, black oxide).

Key Selection Factors: Load capacity, environmental exposure, thermal/electrical needs, and aesthetics.

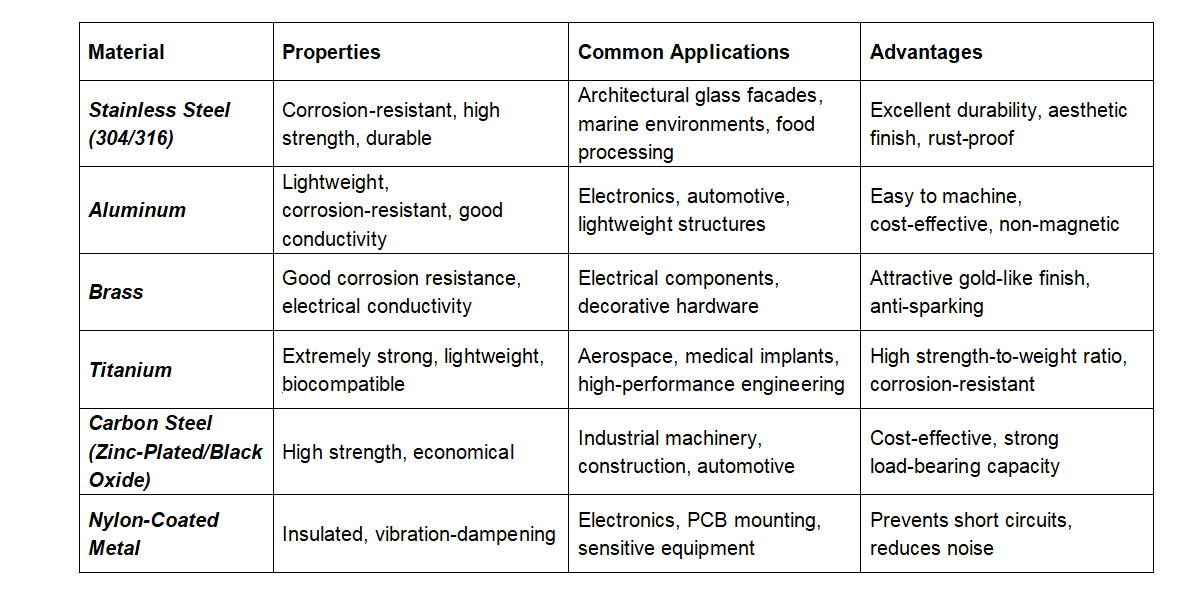

Spacer Materials & Applications

Polestar Metal: Innovative Use of Metal Spacers in High-Tech Architecture

Metal spacers are critical components in modern engineering and design, offering structural support, precise alignment, and aesthetic appeal. Polestar Metal explores how titanium and stainless steel spacers were successfully implemented in the Tower, a futuristic high-rise in Dubai, to achieve unparalleled strength, thermal efficiency, and visual elegance.

Project Overview

Client: Skyline Developments

Location: Dubai, UAE

Application: Curved glass facade with integrated solar panels

Challenge

The architects envisioned a sleek, energy-efficient skyscraper with a double-skin glass facade to reduce heat absorption while maximizing natural light. Key challenges included:

Thermal Expansion: Dubai’s extreme temperatures (up to 50°C/122°F) required spacers that could withstand expansion without compromising structural integrity.

Weight Distribution: The glass panels needed secure yet flexible mounting to prevent stress fractures.

Aesthetic Precision: The design demanded a seamless, floating effect with minimal visible hardware.

Solution: High-Performance Metal Spacers

The engineering team selected titanium alloy spacers for the primary load-bearing points and stainless steel (316-grade) spacers for corrosion resistance in coastal conditions.

Key Features & Benefits:

Thermal Stability – Titanium’s low thermal expansion coefficient prevented warping under heat stress.

Strength & Lightweight Design – Titanium spacers supported heavy glass panels without adding excessive weight.

Corrosion Resistance – Stainless steel spacers resisted saltwater exposure, ensuring longevity.

Adjustable Mounting – Threaded spacers allowed precise alignment during installation.

Implementation & Results

Glass Facade Assembly

Custom titanium standoffs were used to suspend triple-glazed panels, creating an air gap for insulation.

Stainless steel spacers maintained consistent spacing for integrated photovoltaic cells.

Structural Performance

The spacers absorbed wind loads up to 120 km/h (75 mph) without deflection.

No thermal stress cracks were observed after two years of operation.

Energy Efficiency & Aesthetics

The design reduced cooling costs by 30% compared to conventional buildings.

The near-invisible spacer system enhanced the tower’s futuristic appeal.

Impact & Recognition

Client Satisfaction – Skyline Developments reported a 20% increase in leasing demand due to the building’s cutting-edge design.

Conclusion

This project demonstrates how strategic spacer selection can elevate architectural performance, sustainability, and visual impact. Titanium and stainless steel spacers proved indispensable in overcoming thermal, structural, and aesthetic challenges—making them a best-in-class solution for high-tech construction.

Would you like additional details on spacer specifications or alternative applications?

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

评价

目前还没有评价