High Precision Tight Tolerances Custom Small CNC Machining Parts With Versatile Material Compatibility

High Precision Tight Tolerances Custom Small CNC Machining Parts With Versatile Material Compatibility

- 描述

- 用户评价 (0)

描述

What is Small CNC Machining?

Small CNC Machining refers to the use of Computer Numerical Control (CNC) machines to manufacture precision parts with small dimensions , typically ranging from a few millimeters to several centimeters in size. These machines follow digitally programmed instructions (G-code) to cut, drill, mill, or turn materials into highly accurate components with tight tolerances (often within ±0.005 mm or better).

Key Characteristics of Small CNC Machining:

High Precision & Tight Tolerances

Ideal for micro-machining (e.g., tiny gears, medical implants, electronics components).

Achieves sub-millimeter accuracy for complex geometries.

Versatile Material Compatibility

Works with metals (aluminum, stainless steel, titanium), plastics (ABS, PEEK, Delrin), and composites .

Advanced CNC Techniques

Utilizes micro-milling, Swiss turning, wire EDM, and laser machining for intricate details.

Supports multi-axis machining (3-axis, 4-axis, or 5-axis) for complex shapes.

Automated & Repeatable Production

Once programmed, CNC machines produce identical small parts with minimal human intervention.

Suitable for prototyping, low-volume, and high-volume manufacturing .

Applications of Small CNC Machining

Small CNC machining is widely used in industries requiring precision, including:

Electronics & Consumer Goods

Smartphone components (e.g., housings, connectors).

Laptop parts (e.g., heat sinks, brackets).

Wearable devices (e.g., watch cases, buttons).

Medical & Dental

Surgical instruments (e.g., forceps, scalpel handles).

Implants (e.g., titanium bone screws).

Dental prosthetics (e.g., crowns, bridges).

Automotive & Aerospace

Engine components (e.g., fuel injectors, pistons).

UAV (drone) parts.

Lightweight aerospace brackets.

Industrial & Robotics

Precision gears, shafts, and actuators.

Robotic arm joints and connectors.

Prototyping & Custom Parts

Rapid prototyping for product development.

Custom jigs, fixtures, and tooling.

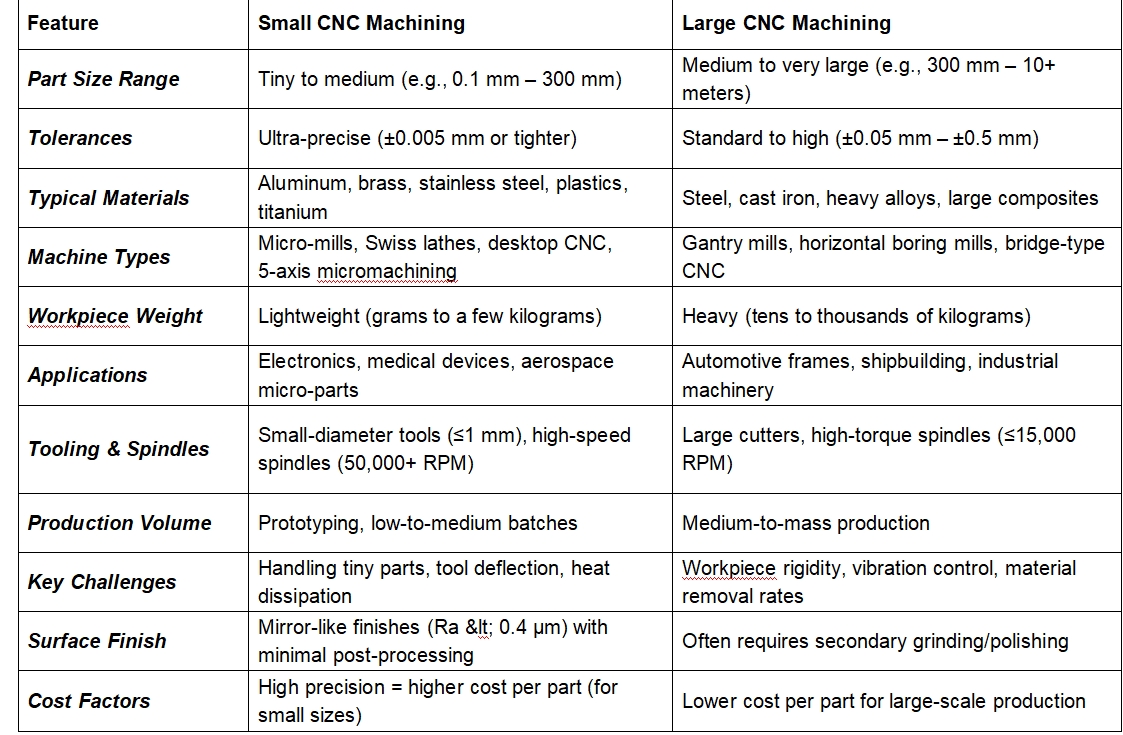

Small CNC Machining vs. Large CNC Machining: Key Differences

Summary of Differences:

Precision vs. Scale :

Small CNC: Focus on micro-scale accuracy and intricate details.

Large CNC: Prioritizes material removal rates and structural integrity.

Machinery :

Small CNC uses compact, high-speed machines (e.g., DATRON, Kern Micro).

Large CNC relies on heavy-duty, high-power machines (e.g., Mazak, DMG MORI).

Industries :

Small CNC: Medical, aerospace, electronics .

Large CNC: Energy, construction, heavy equipment .

Tooling :

Small CNC tools are fragile but ultra-precise .

Large CNC tools are robust but less precise .

Would you like a deeper dive into specific machines or applications?

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

评价

目前还没有评价