Stainless Steel Double Ended Threaded Studs Car Front Suspension Double Headed Stud

Stainless Steel Double Ended Threaded Studs Car Front Suspension Double Headed Stud

- Description

- Reviews (0)

Description

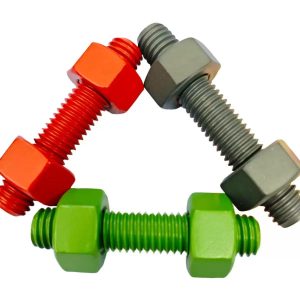

What Are Stainless Steel Double Ended Threaded Studs?

Stainless Steel Double Ended Threaded Studs are heavy-duty fasteners designed with threads on both ends and either a smooth or fully threaded shank in between. They function as high-strength connectors, joining two components where a conventional bolt or screw cannot be used. These studs are particularly valued in applications requiring corrosion resistance, durability, and reliable load-bearing performance.

Materials

Stainless steel double ended threaded studs are manufactured from premium alloys to ensure strength and corrosion resistance. Common materials include:

A2 (304 Stainless Steel) – A versatile, cost-effective option with excellent resistance to oxidation and mild chemicals, suitable for indoor and general industrial use.

A4 (316 Stainless Steel) – Contains molybdenum for enhanced resistance to chlorides, acids, and saltwater, making it ideal for marine, chemical, and offshore applications.

17-4 PH (Precipitation Hardening Stainless Steel) – Offers exceptional strength and corrosion resistance, often used in aerospace, military, and high-temperature environments.

Surface Finishes

To further enhance performance and longevity, these studs undergo various surface treatments:

Natural Finish (Mill Finish) – The standard stainless steel surface, providing inherent corrosion resistance without additional coating.

Electropolished – A electrochemical process that removes surface imperfections, improving corrosion resistance and reducing friction.

Passivated – A chemical treatment that strengthens the protective oxide layer, maximizing rust resistance.

Hot-Dip Galvanized (for hybrid applications) – Though less common for stainless steel, some studs may receive a zinc coating for extreme environments where additional protection is needed.

Specifications of Stainless Steel Double Ended Threaded Studs

Stainless steel double ended threaded studs come in a variety of sizes and configurations:

Thread Standards: Metric (M6, M8, M10, etc.), UNC (Coarse), UNF (Fine), or BSPP (British Standard Pipe Parallel).

Length: Typically ranges from 20mm to 1000mm, with custom lengths available for specialized projects.

Diameter: Common sizes include M4 to M36, with larger diameters used in heavy industrial applications.

Thread Type: Fully threaded or partially threaded (with an unthreaded center section) depending on load distribution needs.

Applications

These studs are widely used in industries where corrosion resistance and structural integrity are critical:

Oil & Gas – Securing flanges, pipelines, and pressure vessels in refineries.

Marine & Offshore – Fastening components on ships, docks, and oil rigs exposed to seawater.

Food & Beverage – Used in processing equipment where hygiene and rust resistance are essential.

Construction – Anchoring structural elements in corrosive environments, such as coastal buildings.

Automotive & Aerospace – High-stress applications like engine blocks and airframe assemblies.

Premium Case: Chemical Processing Plant Reactor Assembly

Challenge:

A leading chemical manufacturer needed a secure fastening solution for a high-pressure reactor vessel handling aggressive acids. Traditional carbon steel bolts corroded rapidly, leading to frequent maintenance and safety risks.

Solution:

Engineers selected A4-316 stainless steel double ended threaded studs with electropolished finish due to their:

Superior acid resistance – Withstanding sulfuric and hydrochloric acid exposure.

High tensile strength – Maintaining structural integrity under extreme pressure.

Easy installation – Double-ended threading allowed for precise torque control during assembly.

Result:

The studs provided a leak-proof, maintenance-free connection for over a decade, eliminating unplanned shutdowns and reducing replacement costs by 60%. This application demonstrated how the right fastener material and design can drastically improve operational efficiency and safety in harsh chemical environments.

Reviews

There are no reviews yet.