ASTM A36 U-Bolt Hot-Dip Galvanized in abrasive high-vibration Industry

ASTM A36 U-Bolt Hot-Dip Galvanized in abrasive high-vibration Industry

- 描述

- 用户评价 (0)

描述

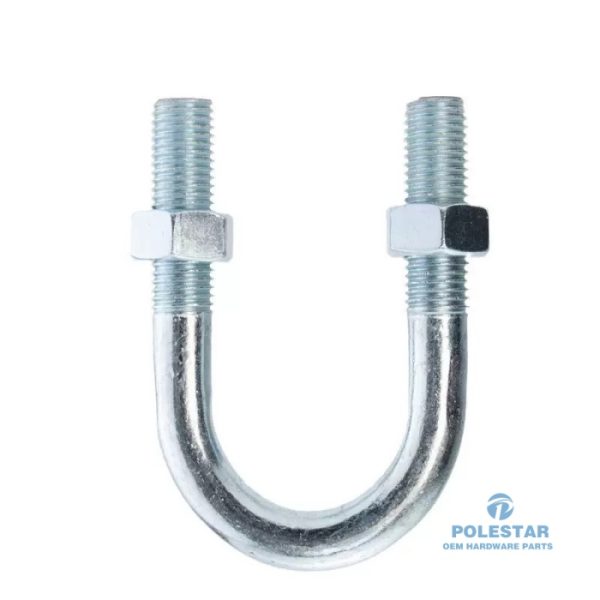

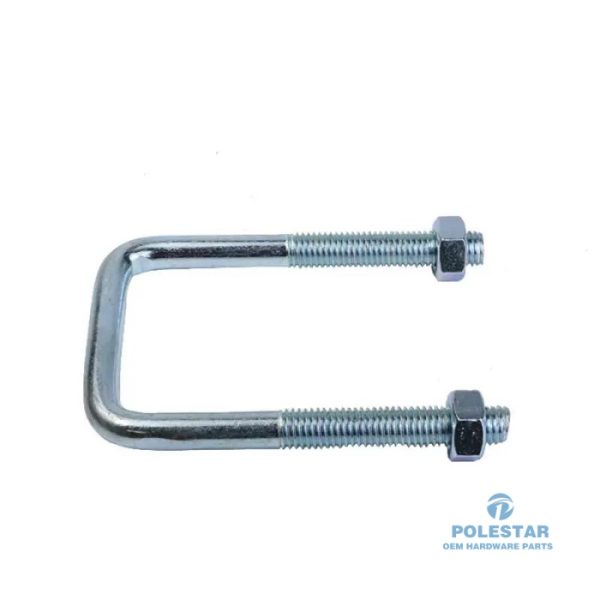

ASTM A36 U-Bolt Hot-Dip Galvanized in abrasive high-vibration Industry

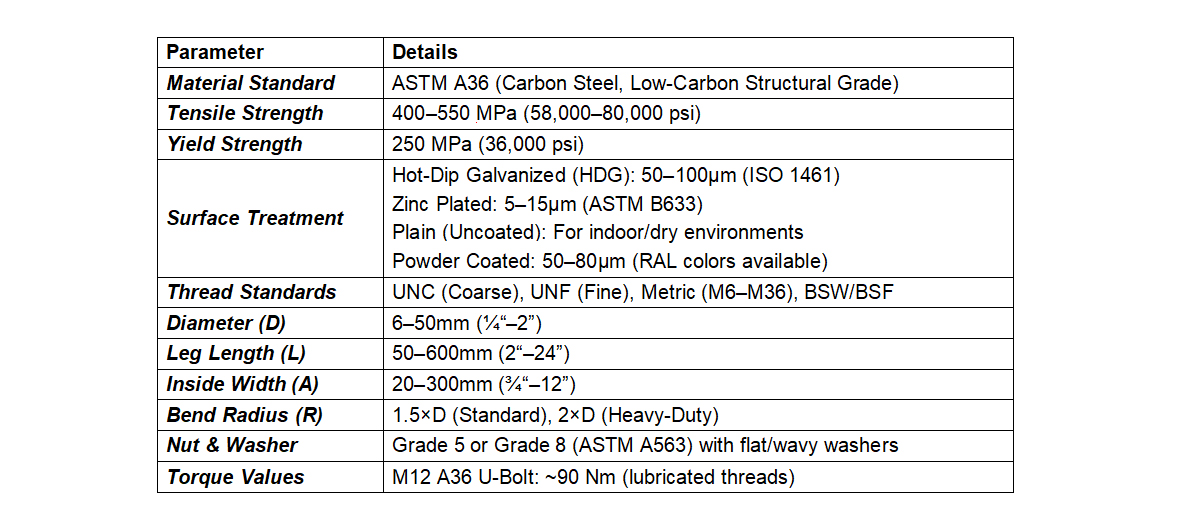

ASTM A36 U-Bolt Specifications

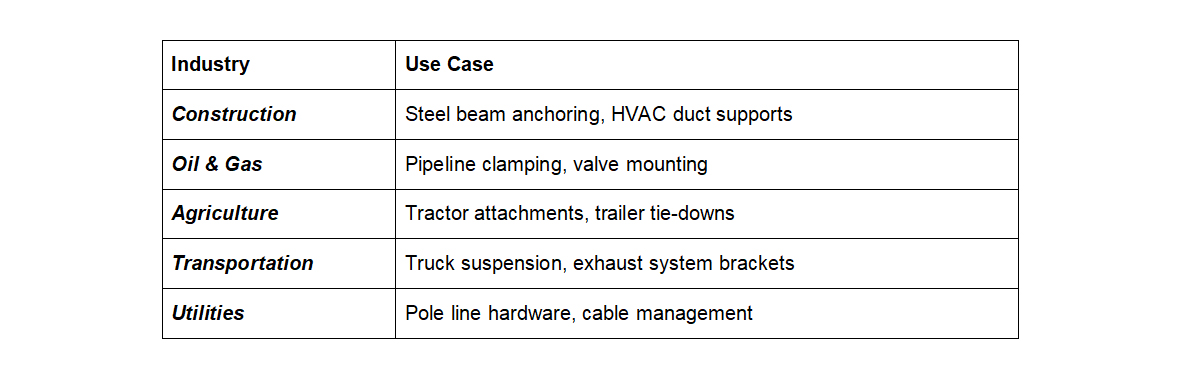

Typical Applications

Advantages of A36 U-Bolts

✔ Cost-Effective : Cheaper than stainless steel (304/316) for moderate environments.

✔ Weldable : Suitable for fabrication projects.

✔ High Strength-to-Weight Ratio : Ideal for structural loads.

✔ Customizable : Bend radius, coating, and thread length adjustable.

Limitations

⚠ Corrosion Risk : Requires galvanizing/painting for outdoor/wet environments.

⚠ Not for Extreme Loads : For higher stress, upgrade to ASTM A307 Grade B or A193 B7 .

Polestar Metal Success Story: A36 U-Bolts in Heavy-Duty Industrial Applications

Project Overview

A leading heavy machinery manufacturer required high-strength, cost-effective fasteners to secure hydraulic pipelines in rugged mining equipment. The challenge was to prevent vibration-induced loosening while withstanding extreme mechanical stress and outdoor corrosion .

Solution: ASTM A36 U-Bolts

Material : ASTM A36 carbon steel (hot-dip galvanized)

Specs :

Diameter: 20mm (¾”)

Leg Length: 200mm (8″)

Inside Width: 100mm (4″)

Threads: UNC coarse (Grade 5.8)

Coating: 80µm hot-dip galvanized (ISO 1461)

Key Benefits Delivered

Durability: Withstood 50,000+ operating hours in abrasive, high-vibration environments.

Corrosion Resistance: Galvanizing prevented rust despite exposure to rain, dust, and chemicals .

Cost Efficiency: 30% cheaper than stainless steel (316) with comparable lifespan in this application.

Easy Installation: Pre-threaded design reduced assembly time by 20% .

Results

Zero failures reported over 3 years of continuous use.

Reduced maintenance costs by eliminating frequent fastener replacements.

Scaled to other projects , including construction crane rigging and off-road vehicle chassis .

Why A36 U-Bolts?

Optimal strength-to-cost ratio for non-marine environments.

Galvanizing extends service life beyond raw carbon steel.

Widely available with short lead times.

Need a similar solution? Contact us for custom U-bolt engineering tailored to your load, corrosion, and budget requirements!

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

评价

目前还没有评价