Aluminum Spacers for Industrial & DIY Projects Round Aluminum Spacer M3 M4 M5 M6 M8 M10

0 out of 5

Aluminum Spacers for Industrial & DIY Projects Round Aluminum Spacer M3 M4 M5 M6 M8 M10

- Description

- Reviews (0)

Description

What Are Aluminum Spacers?

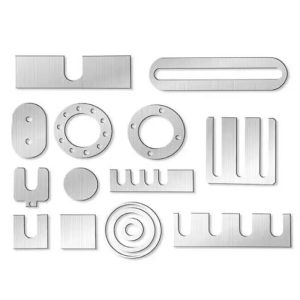

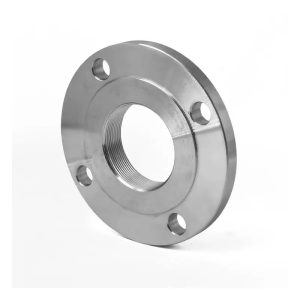

Aluminum spacers are precision-engineered cylindrical components designed to maintain exact spacing and alignment between parts in mechanical assemblies. These versatile fastening solutions feature either hollow or solid construction with smooth or threaded interiors, offering an exceptional combination of lightweight properties, corrosion resistance, and excellent thermal/electrical conductivity. Available in various configurations including round spacers, hexagonal standoffs, and shoulder washers, aluminum spacers serve as critical components in applications where weight reduction and dimensional accuracy are paramount.

Aluminum Spacers: Comprehensive Specifications & Applications

1. Material Options

6061-T6 Aluminum: The most common alloy offering optimal strength (up to 45,000 psi yield strength) and machinability for general applications

5052-H32 Aluminum: Superior marine-grade corrosion resistance with moderate strength

7075-T6 Aluminum: Aerospace-grade alloy with strength comparable to steel (83,000 psi yield)

2024-T3 Aluminum: High fatigue resistance for dynamic load applications

2. Advanced Surface Treatments

Hard Anodizing (Type III): Creates a 0.05mm thick oxide layer with 70+ Rockwell hardness

Color Anodizing (Type II): Provides decorative finishes while maintaining conductivity

PTFE Coating: Reduces friction coefficient to 0.05-0.10 for moving parts

Electroless Nickel Plating: Offers uniform 5-50μm coating for extreme environments

3. Technical Specifications

Diameter Range: 3mm-50mm (standard), up to 100mm (custom)

Length Options: 1mm-300mm (standard), 500mm max (special order)

Thread Types: Metric (M2-M30), UNF/UNC threads (#2-1″)

Tolerances:

Commercial grade: ±0.1mm

Precision grade: ±0.01mm

Aerospace grade: ±0.002mm

4. Industry Applications

Aerospace: Satellite component spacing (CTE matched to composites)

Medical: MRI machine assembly (non-magnetic properties)

Renewable Energy: Solar panel mounting systems (UV resistant)

Transportation: High-speed train bogie insulation (vibration damping)

Defense: Night vision equipment mounting (thermal management)

5. Application Case

Project: Next-Gen Electric Vehicle Battery Pack Assembly

Client: Major European Automotive Manufacturer

Challenge:

Required 2,400 spacers per vehicle to maintain 0.2mm precision between battery cells

Needed to withstand 15G vibration loads

Must prevent galvanic corrosion with copper busbars

Temperature range: -40°C to +120°C

Solution Implementation:

Material Selection: 6061-T6 aluminum with Type III hard anodizing

Custom Design:

12mm diameter with M6 internal threads

0.5mm wall thickness for weight optimization

Serrated contact surfaces for anti-rotation

Performance Results:

Reduced pack weight by 14kg versus steel alternatives

Maintained 0.15mm spacing tolerance after 100,000km simulated testing

Zero corrosion after 1,000-hour salt spray testing

Achieved 98.7% thermal conductivity of pure aluminum

Economic Impact:

Saved €23 per vehicle in material costs

Reduced assembly time by 18 minutes per pack

Extended battery lifecycle by approximately 8%

Reviews

There are no reviews yet.