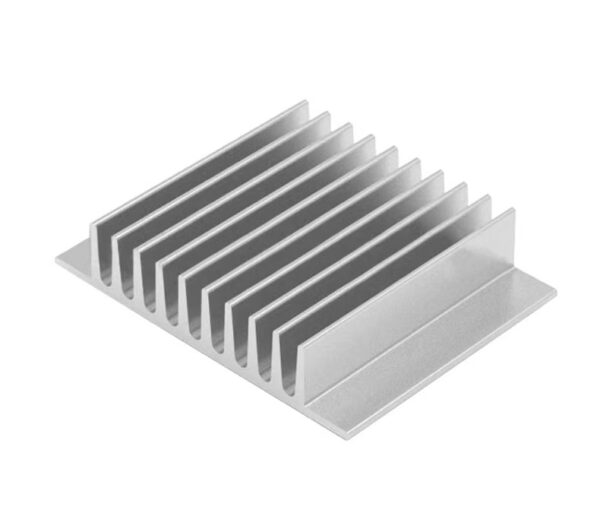

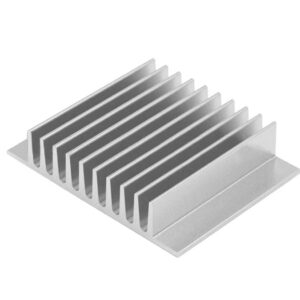

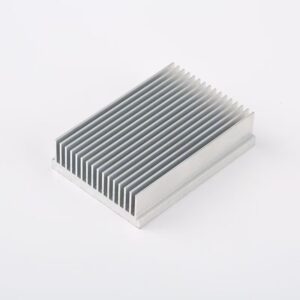

Custom Aluminum Heat Sink CNC Machining Superior Extruded Aluminum Heat Sink

Custom Aluminum Heat Sink CNC Machining Superior Extruded Aluminum Heat Sink

- Description

- Reviews (0)

Description

What is an Aluminum Heat Sink?

An aluminum heat sink is a passive cooling device designed to dissipate heat from electronic components, such as CPUs, GPUs, power transistors, and LED modules. By providing a large surface area for heat transfer, aluminum heat sinks absorb thermal energy from the hot component and release it into the surrounding air, often with the assistance of fans or natural convection.

Aluminum is a preferred material for heat sinks due to its excellent thermal conductivity, lightweight nature, cost-effectiveness, and ease of machining.

Material of Aluminum Heat Sink

Aluminum heat sinks are typically made from the following alloys:

6063 Aluminum: Offers good thermal conductivity (~200 W/m·K) and is easy to extrude into complex shapes.

6061 Aluminum: Stronger than 6063 but slightly less thermally conductive (~170 W/m·K), often used in high-stress applications.

1050/1060 Aluminum: Pure aluminum with excellent thermal conductivity (~230 W/m·K) but lower mechanical strength.

Die-Cast Aluminum (ADC12): Used for intricate shapes but has lower thermal performance than extruded aluminum.

Surface Treatment

To enhance durability, corrosion resistance, and sometimes thermal performance, aluminum heat sinks undergo various surface treatments:

Anodizing (Black or Clear): Improves corrosion resistance and surface hardness while maintaining thermal properties.

Powder Coating: Provides aesthetic appeal and protection but may slightly reduce heat dissipation.

Chemical Conversion Coating (Chromate or Non-Chromate): Prevents oxidation without significantly affecting thermal performance.

Polishing or Sandblasting: Used for aesthetic purposes or to improve surface contact in high-performance applications.

Specifications

Aluminum heat sinks come in various shapes and sizes, with key specifications including:

Dimensions (Length, Width, Height): Customizable based on application requirements.

Fin Density (Fins per Inch): Higher fin density increases surface area but may require forced airflow.

Base Thickness: Thicker bases improve heat absorption from the source.

Thermal Resistance (°C/W): Lower values indicate better heat dissipation efficiency.

Mounting Options: Clips, screws, or thermal adhesive for secure attachment.

Application Fields

Aluminum heat sinks are widely used in industries such as:

Electronics Cooling: CPUs, GPUs, voltage regulators, and power supplies.

LED Lighting: High-power LED modules to prevent overheating and prolong lifespan.

Automotive: Cooling for electric vehicle batteries, inverters, and LED headlights.

Industrial Equipment: Power electronics, motor drives, and RF amplifiers.

Renewable Energy: Solar inverters and wind turbine control systems.

Excellent Case: Cooling High-Performance LED Street Lights

Scenario

A city municipality upgraded its street lighting to energy-efficient high-power LED fixtures. However, the LEDs generated significant heat, risking premature failure and reduced brightness.

Solution

Custom-designed extruded aluminum heat sinks (6063 alloy) were integrated into each LED module. The heat sinks featured:

Optimized Fin Design: Maximized surface area for natural convection cooling.

Black Anodized Finish: Enhanced heat radiation and corrosion resistance in outdoor conditions.

Precise Mounting: Ensured direct contact with LED chips for efficient heat transfer.

Results

Temperature Reduction: LED junction temperatures dropped by 30%, extending lifespan by over 50%.

Energy Efficiency: Maintained consistent light output without additional active cooling.

Low Maintenance: The durable anodized surface resisted weathering, reducing replacement costs.

This case demonstrates how aluminum heat sinks play a critical role in modern infrastructure, ensuring reliability and efficiency in demanding environments.

Reviews

There are no reviews yet.