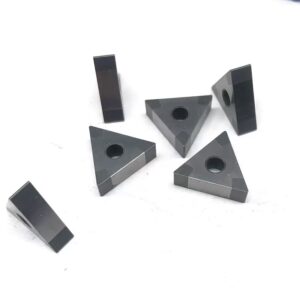

Self Tapping Threaded Inserts Custom Brass Knurled Threaded Repair Insert

0 out of 5

Self Tapping Threaded Inserts Custom Brass Knurled Threaded Repair Insert

Kategoria: Wkładki gwintowane

Tagi: 1 4 20 threaded inserts, 3/8 threaded inserts, Brass Threaded Inserts, heat set threaded inserts, m3 threaded inserts, m5 threaded inserts, self tapping threaded inserts, self tapping threaded inserts for metal, sheet metal threaded inserts, threaded insert, threaded inserts, threaded inserts brass, threaded inserts kit, threaded inserts m6, threaded inserts metal

- Opis

- Opinie (0)

Opis

What Are Self Tapping Threaded Inserts?

Self tapping threaded inserts (also called self-threading inserts or screw-in inserts) are fasteners designed to create strong, reusable threads in soft or damaged materials. Unlike standard threaded inserts that require pre-tapping, these inserts have cutting threads or flutes that allow them to tap their own mating threads when screwed into a pre-drilled hole.

They are commonly used to reinforce weak materials (such as plastic, wood, or thin metal) and provide durable, wear-resistant threads for repeated screw assembly and disassembly.

Key Features of Self Tapping Threaded Inserts

1. Materials

Self-tapping inserts are made from various materials to suit different applications:

Stainless Steel (304, 316) – High corrosion resistance for marine, medical, and outdoor use.

Carbon Steel (Zinc-Plated, Black Oxide) – Cost-effective and strong for industrial applications.

Brass – Good electrical conductivity and corrosion resistance for electronics.

Aluminum – Lightweight and corrosion-resistant for aerospace and automotive.

Nylon/Plastic – Non-conductive and lightweight for electrical insulation.

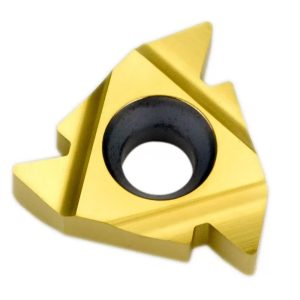

2. Surface Finishes & Coatings

To enhance durability and performance, these inserts often have:

Zinc Plating – Prevents rust in standard environments.

Nickel Plating – Improves wear resistance and provides a smooth finish.

Black Oxide – Reduces glare and offers mild corrosion protection.

Passivation (for Stainless Steel) – Enhances corrosion resistance.

PTFE (Teflon) Coating – Reduces friction for easier installation.

3. Common Sizes & Specifications

Thread Sizes: Metric (M2, M3, M4, M5, M6) and Imperial (#4-40, #6-32, #8-32, #10-24).

Outer Diameter (OD): Varies based on material thickness (typically 3mm–12mm).

Length: 5mm–20mm (custom lengths available).

Drive Types: Hex key (Allen), slotted, or external hex for installation.

Flute Design: Single or multi-flute for better chip removal in plastic/metal.

4. Applications

Self-tapping threaded inserts are widely used in industries where strong, reusable threads are needed in soft or low-density materials:

✔ Motoryzacja – Securing interior panels, sensors, and electrical components in plastic housings.

✔ Elektronika – Reinforcing screw threads in plastic casings (laptops, routers, etc.).

✔ Aerospace – Lightweight fastening in composite materials.

✔ Furniture & Woodworking – Adding durable threads to MDF, plywood, or particleboard.

✔ Medical Devices – Providing secure fastening in plastic surgical equipment.

✔ Industrial Machinery – Repairing stripped threads in soft metals like aluminum.

Excellent Case: Reinforcing Plastic Housing in Electric Vehicle (EV) Battery Systems

Challenge:

An EV battery manufacturer needed a reliable way to secure high-voltage wiring connectors inside plastic battery housings. The problem was:

Plastic threads wore out quickly due to frequent maintenance checks.

Standard screws stripped the plastic after a few installations.

Vibration resistance was critical to prevent loosening.

Solution:

Stainless Steel Self-Tapping Threaded Inserts (M5, Hex Drive, 10mm Length) were installed into pre-drilled holes in the plastic housing.

The self-tapping flutes cut precise threads without cracking the plastic.

Stainless steel (316 grade) resisted corrosion from battery chemicals.

Hex drive allowed easy installation with a standard Allen wrench.

Knurled outer surface improved grip in the plastic to prevent rotation.

Result:

✅ Durable threads survived 50+ assembly/disassembly cycles without wear.

✅ No more stripped screws, reducing maintenance costs.

✅ Vibration-resistant due to the metal-to-plastic locking design.

✅ Faster servicing since technicians could repeatedly remove/reinstall screws without damaging the housing.

Conclusion

Self-tapping threaded inserts are essential for creating strong, long-lasting threads in soft materials. Their versatile materials, coatings, and designs make them ideal for automotive, electronics, aerospace, and industrial applications where durability and reusability matter.

For high-stress environments (like EVs or machinery), these inserts prevent thread failure and extend product lifespan.

Opinie

Na razie nie ma opinii o produkcie.