High Precision Misalignment Spacers CNC Machined Metal Spacer Stainless Steel Aluminum

0 out of 5

High Precision Misalignment Spacers CNC Machined Metal Spacer Stainless Steel Aluminum

Kategoria: Metalowe elementy dystansowe

Tagi: 3 4 to 1 2 misalignment spacer, 3 4 to 9 16 misalignment spacer, 9 16 misalignment spacer, adjustment shims, aluminum spacers, cnc machined spacers, cnc machining parts, cnc turned spacers, eccentric spacers, heim joint misalignment spacer, m8 metal spacers, Metal Spacer, Metalowe elementy dystansowe, metal spacers screwfix, misalignment spacer, round metal spacers, shims for alignment adjustment, stainless misalignment spacer, Stainless Steel Spacers, valve adjustment shims

- Opis

- Opinie (0)

Opis

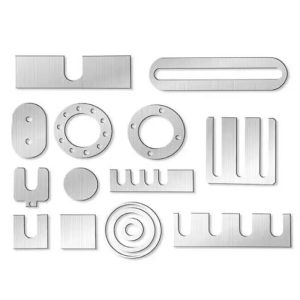

What are Misalignment Spacers?

Misalignment spacers (also called eccentric spacers or adjustment shims) are precision-engineered components used to correct minor axial or radial misalignments between mating parts in mechanical assemblies. These spacers feature offset or tapered designs that allow fine-tuning of component positioning without requiring permanent modifications to the base structure.

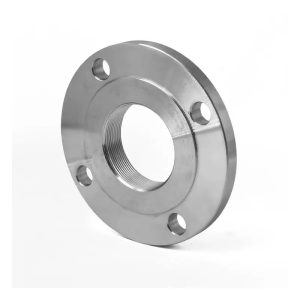

Materials of Misalignment Spacers

Stainless Steel (304/316) – Corrosion-resistant for harsh environments.

Carbon Steel (Grade 1018/1045) – Cost-effective for general industrial use.

Aluminum (6061-T6) – Lightweight, ideal for aerospace/automotive.

Brass/Bronze – Low friction and wear-resistant for rotating parts.

PTFE-Coated Steel – Self-lubricating for high-wear applications.

Surface Treatments

Zinc Plating – Basic rust protection (indoor/mild environments).

Hard Anodizing (Aluminum) – Improves wear resistance.

Black Oxide – Reduces glare and provides mild corrosion resistance.

Electropolishing (Stainless Steel) – Smooth finish for cleanroom use.

Powder Coating – Custom colors and added durability.

Specifications

Types:

Eccentric Spacers (Offset bore for radial adjustment).

Tapered Spacers (Angular correction).

Slotted Spacers (Lateral adjustment).

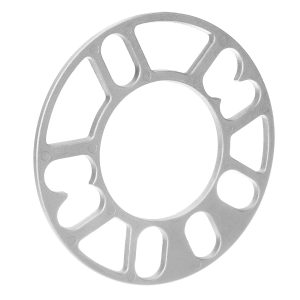

Size Range: 3mm to 150mm OD, with 0.1mm–5mm adjustability.

Tolerances: Typically ±0.02mm for precision applications.

Standards: DIN 988 (metric), ANSI B18.22.1 (imperial).

Applications

Robotics: Aligning robotic arm joints for precision movement.

Conveyor Systems: Correcting roller/pulley misalignment.

Motoryzacja: Wheel hub centering, transmission assemblies.

Aerospace: Engine mount adjustments.

Medical Equipment: MRI/X-ray component alignment.

Excellent Case: Industrial Conveyor Belt Realignment

Challenge: A food processing plant experienced excessive belt wear due to a 2mm misalignment in the drive rollers, causing downtime and product spillage.

Solution:

Installed stainless steel eccentric spacers (50mm OD, 0.5mm offset) on the roller shafts.

Adjusted spacers to compensate for misalignment without disassembling the frame.

Surface-treated with FDA-compliant electropolishing for hygiene.

Result:

Belt Life Increased by 300% – Eliminated edge wear.

Zero Downtime – Adjustment took <30 minutes vs. 4 hours for structural fixes.

Hygiene Compliance – Met NSF/3A sanitation standards.

Opinie

Na razie nie ma opinii o produkcie.