CNC Turned Threaded Studs Steel Stainless Steel Brass Bronze Titanium

CNC Turned Threaded Studs Steel Stainless Steel Brass Bronze Titanium

- Opis

- Opinie (0)

Opis

CNC Turned Threaded Studs Steel Stainless Steel Brass Bronze Titanium

Threaded Studs – Technical Specifications

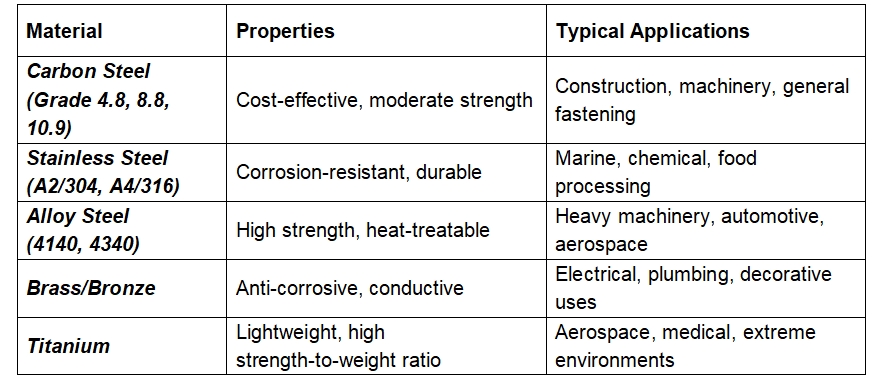

Common Materials

Standard Sizes & Specifications

Diameter (D): M3 to M64 (metric), #4 to 2″ (imperial)

Length (L): 10mm to 1000mm (custom lengths available)

Thread Types:

Metric (ISO): Coarse (e.g., M8x1.25) / Fine (e.g., M8x1)

Imperial: UNC (coarse), UNF (fine), BSW, BSF

Special: ACME, trapezoidal (for load-bearing applications)

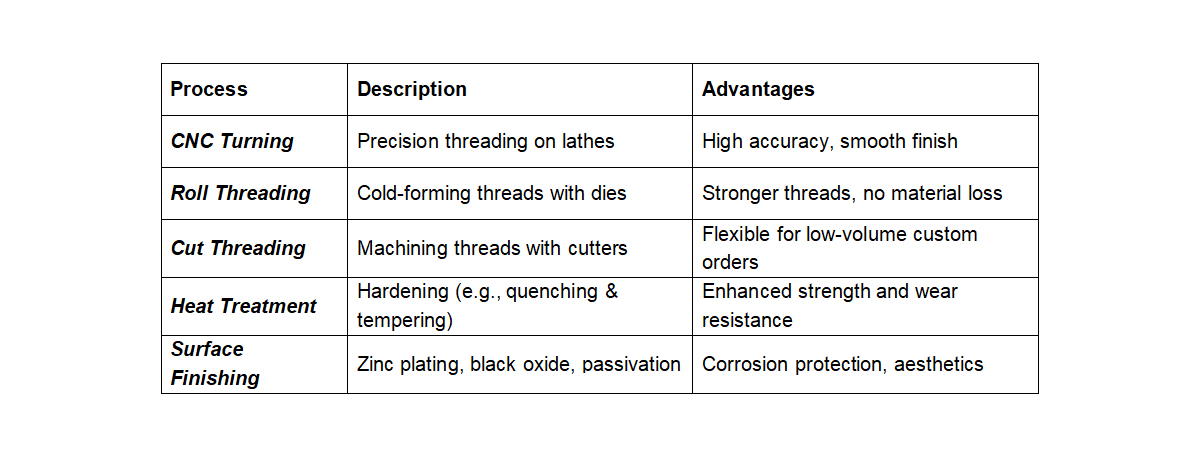

Manufacturing Processes

Key Applications

Key Applications

Automotive: Engine mounts, exhaust systems

Construction: Steel structures, anchor bolts

Industrial: Piping systems, pressure vessels

Electronics: Heat sinks, PCB mounting

Energy: Wind turbines, oil rigs

Quality Standards

ISO 898-1: Mechanical properties of carbon/alloy steel studs

ASTM A193: High-temperature alloy studs

DIN 975: Metric threaded stud dimensions

ASME B18.31.1: Imperial threaded stud specifications

Notes for Custom Orders:

Tolerances: Typically ±0.1mm (higher precision available).

Certifications: Material test reports (MTRs), RoHS/REACH compliance.

Packaging: Bulk, blister packs, or custom kitting

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medycyna i stomatologia: narzędzia chirurgiczne, urządzenia do implantacji, mikrozłącza.

Elektronika: mikrozłącza, obudowy czujników, mocowania PCB.

Lotnictwo i obrona: lekkie wsporniki, komponenty do dronów, specjalistyczne elementy złączne.

Motoryzacja: Części do wtrysku paliwa, niestandardowe elementy złączne, komponenty EV.

Dlaczego warto wybrać nas?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Key Applications

Key Applications

Opinie

Na razie nie ma opinii o produkcie.