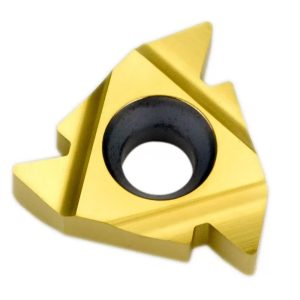

Superior Stainless Steel Self Tapping Thread Inserts with Three Cutting Holes

Superior Stainless Steel Self Tapping Thread Inserts with Three Cutting Holes

- Beschrijving

- Beoordelingen (0)

Beschrijving

What Are Self Tapping Thread Inserts?

Self-tapping thread inserts are precision-engineered fastening components designed to create or restore strong, durable threads in soft or damaged materials. Unlike standard threaded inserts, they feature cutting edges or forming lobes on their exterior that allow them to tap their own mating threads during installation—eliminating the need for pre-tapping in many cases.

These inserts provide a reinforced threaded hole, improving load distribution and resistance to wear, vibration, and pull-out forces. They are widely used in industries where traditional threading methods may fail due to material limitations or frequent disassembly.

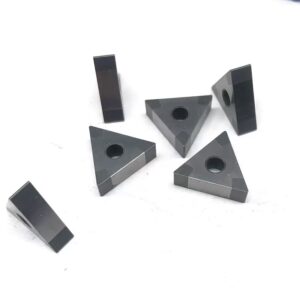

Materials Used in Self Tapping Thread Inserts

The choice of material depends on the application’s mechanical, thermal, and corrosion resistance requirements:

Stainless Steel (Grade 304/316) – Ideal for corrosive environments, food processing, and marine applications.

Carbon Steel (Hardened & Coated) – High-strength option for industrial machinery, often zinc-plated for rust resistance.

Brass – Used in electrical and plumbing applications due to its anti-sparking and anti-galling properties.

Aluminum – Lightweight and corrosion-resistant, commonly used in aerospace and automotive industries.

High-Temperature Alloys (Inconel, Monel, Titanium) – For extreme heat and chemical exposure, such as in jet engines or chemical processing equipment.

Free-Cutting Steel (Lead-Alloyed) – Easier to install in hard materials while maintaining strength.

Surface Treatments for Enhanced Performance

To improve durability and functionality, self tapping thread inserts often undergo specialized coatings:

Zinc Plating (Yellow or Clear) – Basic corrosion protection for steel inserts.

Black Oxide – Reduces friction and provides mild rust resistance.

PTFE (Teflon) Coating – Prevents thread galling and seizing in high-temperature or stainless-steel applications.

Nickel Plating – Enhances hardness and corrosion resistance in harsh environments.

Passivation (for Stainless Steel) – Removes free iron particles to maximize corrosion resistance.

Electroless Nickel (ENP) – Uniform coating for wear resistance in precision applications.

Common Specifications & Sizes

Self tapping thread inserts are available in various configurations to match different needs:

Thread Types: Metric (M2–M24), UNC/UNF (#4–1″), BSP, and special thread forms.

Length Options: Typically 1.5× to 3× the nominal diameter (e.g., M6x10mm).

Drive Styles: Hex socket, slotted, external wrench flats, or installation tangs.

Installation Methods: Manual (hand tools), pneumatic drivers, or electric screwdrivers.

Thread Locking Features: Some include nylon patches or adhesive for vibration resistance.

Key Application Areas

Self tapping thread inserts are essential in industries requiring reliable, long-lasting threaded connections:

Automotive & Motorsports – Repairing stripped threads in engine blocks, transmission cases, and aluminum components.

Aerospace – Securing fasteners in lightweight aluminum or composite structures.

Electronics & Appliances – Providing durable threads in plastic housings or thin metal sheets.

Industrial Machinery – Reinforcing threads in cast iron, steel, or soft alloys subjected to heavy loads.

Marine & Offshore – Stainless steel inserts prevent corrosion in saltwater-exposed components.

Medical Devices – Precision inserts for surgical instruments and diagnostic equipment.

Renewable Energy – Wind turbine assemblies and solar panel mounting systems.

Excellent Case: Repairing a Stripped Cylinder Head in a High-Performance Engine

The Challenge

A racing team faced a critical issue when a spark plug thread in their aluminum cylinder head stripped during a high-heat endurance race. Traditional thread repair methods (like helicoils) were unreliable under extreme vibration and thermal cycling.

The Solution

The team selected a stainless steel self tapping thread insert with a PTFE coating for its:

✔ Self-tapping design – Eliminated the need for separate tapping, saving time.

✔ High-temperature resistance – Withstood combustion chamber heat.

✔ Anti-seize properties – PTFE coating prevented thread galling during plug changes.

Using a manual insertion tool, the insert was driven into the damaged hole, where its sharp external threads cut precise new grooves. The installation took less than 5 minutes, with no machining required.

The Result

The repaired thread held 30% more torque than the original aluminum thread.

No thread degradation occurred even after 50+ spark plug removals/reinstallations.

The engine performed flawlessly in subsequent races, proving the insert’s reliability under extreme conditions.

Why Choose Self Tapping Thread Inserts?

✔ Faster installation – No pre-tapping needed in most cases.

✔ Stronger threads – Distributes load better than direct threading.

✔ Longer service life – Resists wear, vibration, and corrosion.

✔ Versatile – Works in plastics, soft metals, and composites.

Whether for repairing damaged threads or reinforcing weak materials, self-tapping inserts provide a cost-effective, high-performance solution across countless industries.

Beoordelingen

Er zijn nog geen beoordelingen.