Precision CNC Machined Screws Slotted Phillips PH Torx Star Square Drive

Precision CNC Machined Screws Slotted Phillips PH Torx Star Square Drive

- Beschrijving

- Beoordelingen (0)

Beschrijving

Precision CNC Machined Screws Slotted Phillips PH Torx Star Square Drive

Material Options: Common choices include carbon steel (standard), stainless steel (corrosion-resistant), brass (conductive), and titanium (high-strength).

Thread Types: Fully threaded (entire shank) or partial (shoulder screws).

Standards: ISO (international), ASME/DIN (regional), or custom specifications.

Drive Types: Hex (Allen), Phillips, slotted, Torx, or specialized (e.g., thumb-operated).

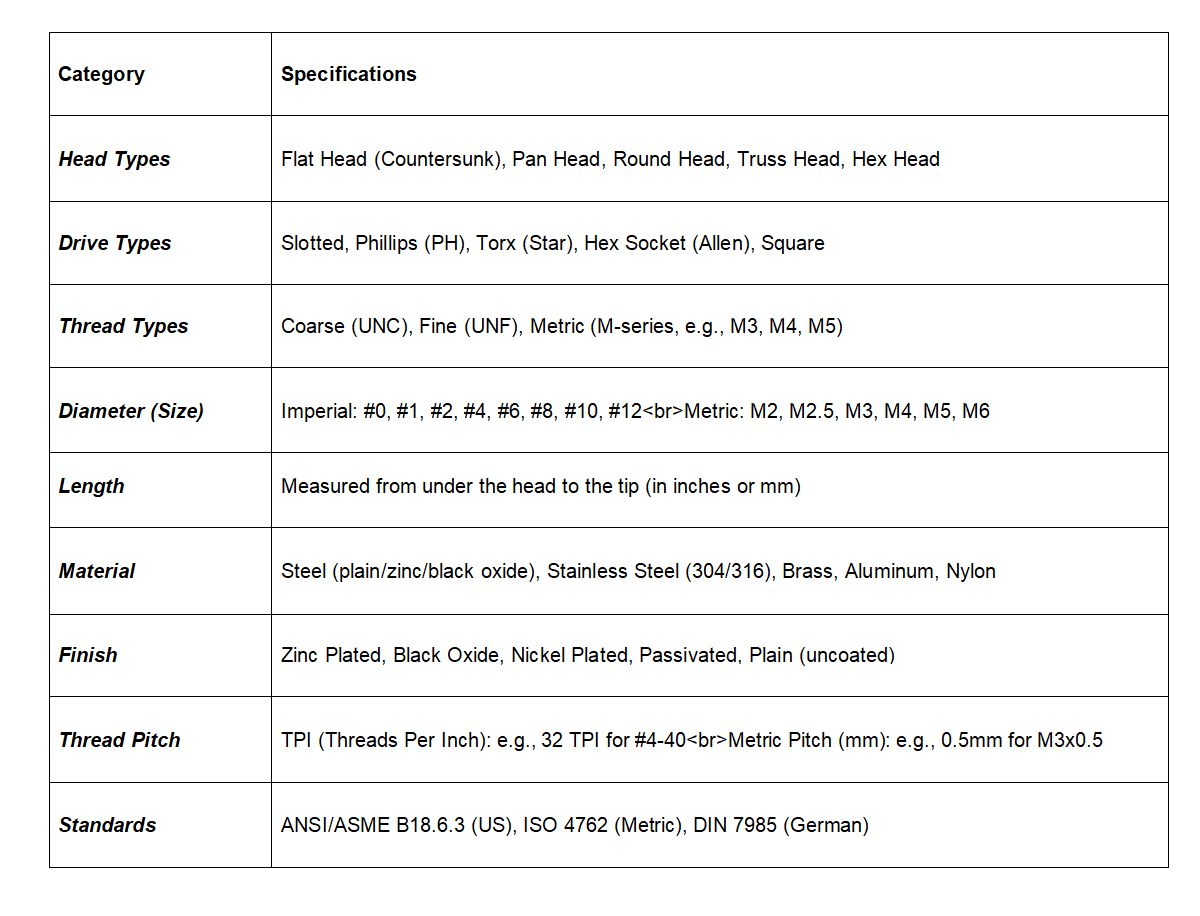

Specification

Below are some successful cases on our CNC Machined Screws.

Case 1: Aerospace Fasteners

Application: High-strength titanium screws for aircraft structural components.

Challenge: Needed lightweight yet ultra-durable fasteners to withstand extreme stress and corrosion.

Solution:

Material: Grade 5 Titanium (Ti-6Al-4V)

Process: Precision CNC machining with tight tolerances (±0.005mm).

Result:

40% weight reduction vs. steel screws.

Corrosion-resistant for harsh environments.

Met AS9100 aerospace standards.

Case 2: Medical Implant Screws

Application: Bone fixation screws for orthopedic surgery.

Challenge: Biocompatibility and precision were critical for patient safety.

Solution:

Material: Medical-grade stainless steel (316L) & titanium.

Process: CNC machining with mirror-finish polishing (Ra <0.2µm).

Result:

FDA-approved for implantation.

Zero rejection rate in sterility testing.

Custom thread design improved bone grip by 25% .

Case 3: Automotive Turbocharger Assembly

Application: Heat-resistant screws for turbocharger housings.

Challenge: Required screws to endure 800°C+ temperatures without loosening.

Solution:

Material: Inconel 718 (nickel alloy).

Process: CNC machining + thread locking treatment .

Result:

No thermal deformation after 100+ test cycles.

Vibration resistance exceeded ISO 16047 standards.

Extended turbo lifespan by 30% .

Case 4: Robotics Precision Joints

Application: Miniature screws for robotic arm actuators.

Challenge: Needed micro-sized screws (M1.2) with zero backlash.

Solution:

Material: A2 stainless steel with self-lubricating coating .

Process: Swiss-type CNC machining (±0.002mm tolerance).

Result:

Smooth motion control with <0.01mm positional error.

Reduced assembly time by 50% vs. traditional screws.

Case 5: Semiconductor Equipment

Application: Non-magnetic screws for wafer handling robots.

Challenge: Avoiding magnetic interference in cleanroom environments.

Solution:

Material: Aluminum 6061 with anodized coating .

Process: High-speed CNC machining (50,000 RPM spindle).

Result:

Passed Class 10 cleanroom certification.

Eliminated particle contamination risks.

Key Takeaways:

Material innovation (titanium, Inconel) solves extreme-condition challenges.

Precision CNC machining ensures reliability in critical applications.

Custom designs (threads, coatings) enhance performance.

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Beoordelingen

Er zijn nog geen beoordelingen.