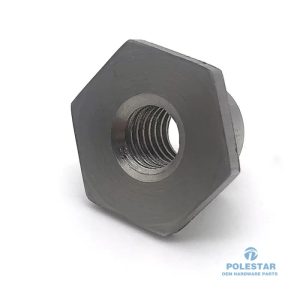

Carbon Steel Grade 8 Castle Nuts with Cotter Pins 5/8-18 Crown Nut Hex with Groove

0 out of 5

Carbon Steel Grade 8 Castle Nuts with Cotter Pins 5/8-18 Crown Nut Hex with Groove

Categorie: Machined Nuts

Tags: aluminum nuts, brass castle nuts, brass nuts, carbon steel nuts, castle nuts, castle nuts and bolts, castle nuts autozone, castle nuts cotter pins, castle nuts lowes, castle nuts with cotter pins, CNC Machined Nuts, CNC Machining Nuts, crown lug nuts, crown nuts, crown nuts and bolts, custom metal nuts, hex castle nuts, Machined Nuts, metric castle nuts, slotted castle nuts, stainless castle nuts, stainless steel nuts, thin castle nuts

- Beschrijving

- Beoordelingen (0)

Beschrijving

What are Castle Nuts with Cotter Pins?

Castle nuts with cotter pins are a secure fastening system designed to prevent loosening under vibration or dynamic loads. The castle nut (a slotted nut) pairs with a cotter pin (a bent metal pin) that inserts through both the nut’s slots and a cross-drilled hole in the bolt, creating a positive mechanical lock. This assembly ensures the nut cannot rotate off without removing the pin.

Materials

Castle Nuts

Carbon Steel (Grade 5/8) – High strength for automotive/industrial use.

Stainless Steel (304/316) – Corrosion-resistant for marine/outdoor applications.

Alloy Steel (AISI 4140) – Heat-treated for extreme loads (e.g., heavy machinery).

Brass – Non-sparking, used in plumbing/electrical systems.

Aluminum – Lightweight (aerospace applications).

Cotter Pins

Stainless Steel (302/304) – Rust-proof for harsh environments.

Carbon Steel – Zinc-plated for general use.

Monel – High corrosion resistance (marine/chemical industries).

Bronze – Non-magnetic and wear-resistant.

Surface Treatments

Castle Nuts:

Zinc plating (most common).

Hot-dip galvanizing (for outdoor/marine use).

Black oxide (military/aerospace).

Passivation (stainless steel).

Cotter Pins:

Zinc plating (basic corrosion resistance).

Stainless steel (natural finish, no coating needed).

Specifications

Thread Sizes: #10 to 1½” (UNC/UNF or metric).

Nut Height: Taller than standard nuts to fit cotter pins.

Pin Diameters: 1/16″ to 1/4″ (matched to bolt hole size).

Standards:

DIN 935 / ISO 7035 (castle nuts).

ASTM F594 (cotter pins).

MIL-SPEC (for defense applications).

Applications Castle Nuts with Cotter Pins

Automotive: Wheel bearings, suspension linkages.

Aerospace: Flight control systems, landing gear.

Industrial Machinery: Rotating shafts, hydraulic cylinders.

Rail/Marine: Securing critical bolted joints.

Agriculture: Tractor/implement assemblies.

Excellent Case: Aircraft Landing Gear Assembly

Challenge: A commercial aircraft manufacturer needed to ensure the landing gear pivot bolts remained secure despite constant vibration and shock loads during takeoff/landing.

Solution:

Used AISI 4140 alloy steel castle nuts (heat-treated) with stainless steel cotter pins.

Precision-drilled bolt holes to ensure perfect pin alignment.

Applied black oxide coating for corrosion resistance.

Result:

Zero Incidents: No reported loosening in 10+ years of fleet operation.

FAA Compliance: Met strict aviation safety standards (FAR 25.607).

Maintenance Efficiency: Quick visual inspection confirmed pin integrity.

Beoordelingen

Er zijn nog geen beoordelingen.