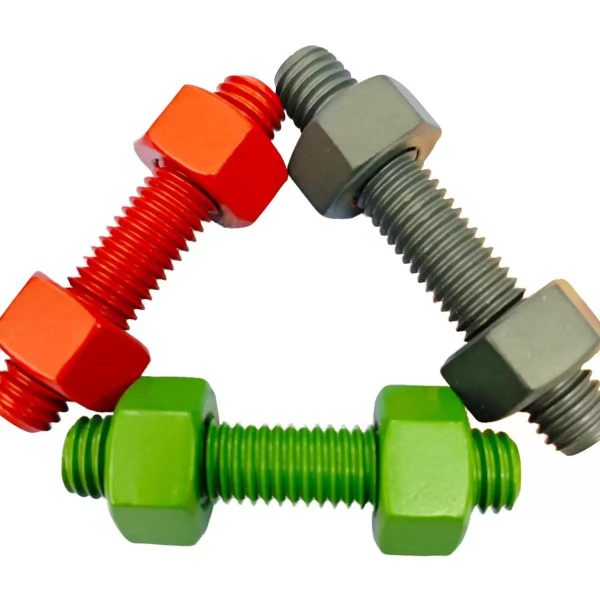

Full Threaded Rod Studs Teflon Coated Carbon Steel Stud Rods with Bolts and Nuts

0 out of 5

Full Threaded Rod Studs Teflon Coated Carbon Steel Stud Rods with Bolts and Nuts

Categorie: Threaded Studs

Tags: 3/8 threaded studs, 316 stainless threaded studs, 5 16 18 threaded studs, 6mm threaded studs, aluminum threaded studs, brass threaded studs, custom threaded studs, double ended threaded studs, double threaded studs, fully threaded studs, grade 8 threaded studs, m6 threaded studs, metal teflon coating, metric threaded studs, nelson threaded studs, partially threaded studs, ptfe coating, teflon coating, teflon coating services, teflon ptfe coating, teflon threaded studs, threaded rod and studs, threaded rod studs, threaded studs, threaded studs bolts, threaded studs for steel, threaded studs stainless steel

- Beschrijving

- Beoordelingen (0)

Beschrijving

What Are Threaded Rod Studs?

Threaded rod studs, also known as stud bolts or threaded bars, are long, straight metal rods with threading on both ends (or along the entire length). They are commonly used with nuts and washers to fasten or assemble structures where a secure, adjustable, and durable connection is needed.

Materials

Threaded rod studs are available in a variety of materials to suit different environments and load requirements:

Carbon Steel (Grade 2, Grade 5, Grade 8) – General-purpose, cost-effective, and strong.

Stainless Steel (304, 316) – Corrosion-resistant, ideal for outdoor or marine applications.

Alloy Steel (A193 B7, B8) – High strength, used in heavy-duty and high-temperature environments.

Brass – Decorative and corrosion-resistant, often used in plumbing and electrical applications.

Aluminum – Lightweight and corrosion-resistant, suitable for aerospace and automotive uses.

Surface Treatments

To enhance durability and performance, threaded rod studs can undergo various surface treatments:

Zinc Plating (Galvanized) – Provides corrosion resistance for indoor and outdoor use.

Hot-Dip Galvanizing – Thicker zinc coating for extreme environments.

Black Oxide – Improves wear resistance and reduces glare.

Chrome Plating – Adds corrosion resistance and a polished appearance.

PTFE (Teflon) Coating – Reduces friction and provides chemical resistance.

Specifications

Threaded rod studs come in different sizes and standards:

Diameter: M3 to M100 (metric) or #4 to 4 inches (imperial).

Length: Customizable, typically ranging from 50mm to 3000mm.

Thread Type: Coarse (UNC), Fine (UNF), or Metric (M).

Standards: DIN 975, DIN 976, ASTM A193, ISO 898.

Applications

Threaded rod studs are widely used in:

✔ Construction – Suspended ceilings, HVAC systems, structural supports.

✔ Automotive – Engine components, chassis assembly.

✔ Manufacturing – Machinery, equipment assembly.

✔ Marine & Offshore – Corrosion-resistant fastening.

✔ Electrical & Plumbing – Conduit supports, pipe hangers.

✔ DIY & Furniture – Adjustable shelving, modular structures.

Excellent Use Case: Chemical Processing Plant

A chemical processing plant needed corrosion-resistant fasteners for assembling pipe flanges in a highly acidic environment. Standard steel studs would corrode quickly, leading to leaks and maintenance issues.

Solution:

The plant switched to Teflon-coated carbon steel threaded rod studs, which provided:

Chemical resistance against acids and solvents.

Longer lifespan compared to uncoated or zinc-plated studs.

Easy installation with reduced friction, allowing smooth nut tightening.

Result:

Zero corrosion issues even after 2+ years in harsh conditions.

Reduced downtime due to fewer replacements.

Cost savings from lower maintenance and longer-lasting fasteners.

Beoordelingen

Er zijn nog geen beoordelingen.