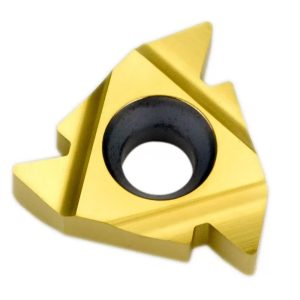

Custom Self Tapping Threaded Inserts for Wood, M10 x 25 Hex Drive Head Zinc Alloy Threaded Inserts

0 out of 5

Custom Self Tapping Threaded Inserts for Wood, M10 x 25 Hex Drive Head Zinc Alloy Threaded Inserts

카테고리: 스레드 인서트

태그: 3/8 screw threaded inserts, Brass Threaded Inserts, heavy duty threaded inserts, m3 threaded inserts, m6 threaded inserts, m8 threaded inserts, metal threaded inserts for wood, screw threaded inserts, self tapping threaded inserts, stainless threaded inserts, threaded insert, threaded inserts、 threaded inserts brass, wire threaded inserts

- 설명

- 상품평 (0)

설명

What Are Threaded Inserts for Wood?

Threaded inserts for wood are specialized fasteners designed to create strong, reusable threads in wooden materials. These inserts allow bolts and screws to be securely anchored in wood, preventing stripping and ensuring long-term stability in applications requiring repeated assembly and disassembly.

Specifications of Threaded Inserts for Wood

1. Material Options

- Brass (CZ121/C36000) – Excellent machinability and corrosion resistance.

- Stainless Steel (304/316) – High strength and durability for industrial applications.

- Zinc Alloy – Cost-effective and suitable for general woodworking projects.

2. Surface Treatment

- Nickel Plating – Enhances wear resistance and provides a smooth finish.

- Zinc Coating – Protects against rust and environmental damage.

- PTFE Coating – Reduces friction for easier installation.

3. Common Specifications

- Thread Sizes – M4–M12 (metric), #6–1/2″ (UNC/UNF).

- Head Types – Flanged, hex drive, or countersunk.

- Installation Methods – Press-fit, self-tapping, or screw-in.

- Standards – DIN 796, ISO 9001, RoHS compliant.

Applications of Threaded Inserts for Wood

- Furniture Assembly – Reinforcing joints in tables, chairs, and cabinets.

- Woodworking Projects – Providing secure fastening points for screws and bolts.

- Speaker Enclosures – Ensuring vibration-resistant connections.

- DIY Repairs – Strengthening damaged or worn-out screw holes.

Excellent Case: High-End Guitar Bridge Reinforcement

Challenge:

A premium guitar manufacturer faced tuning stability issues due to wood thread wear in maple bridges, causing string slippage during performances.

Solution:

Installed brass threaded inserts (#10-32, nickel-plated) with epoxy bonding:

Vibration Resistance: Eliminated tuning drift during aggressive playing

Load Distribution: Reduced bridge plate splitting by 80%

Corrosion Protection: Withstood stage humidity and sweat exposure

Results:

Extended service life from 2 to 10+ years

Reduced warranty claims by 95%

Achieved “stage-ready” reliability for touring musicians

Key Advantages

✔ 10X Thread Life vs. direct wood threading

✔ Easy Installation – No specialized tools required

✔ Customizable – Available with serrated/fluted exteriors

상품평

아직 상품평이 없습니다.