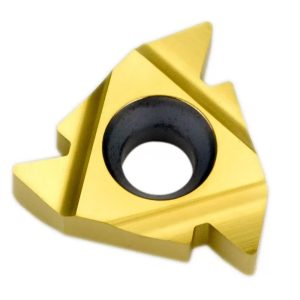

OEM Flanged Threaded Inserts High Strength Carbon Steel Galvanized Flanged Insert

0 out of 5

OEM Flanged Threaded Inserts High Strength Carbon Steel Galvanized Flanged Insert

카테고리: 스레드 인서트

태그: 3/8 threaded inserts, 5/16 threaded inserts, aluminum threaded inserts, carbon steel threaded inserts, flanged inserts, flanged threaded inserts, flanged threaded inserts for metal, flanged threaded inserts for plastic, flanged threaded inserts for wood, furniture threaded inserts, stainless steel threaded inserts, threaded inserts, threaded inserts brass, threaded inserts for sheet metal, threaded inserts m6, threaded inserts metal, threaded inserts nuts, threaded inserts steel

- 설명

- 상품평 (0)

설명

Flanged Threaded Inserts: Definition and Key Features

What Are Flanged Threaded Inserts?

Flanged Threaded Inserts are specialized threaded fasteners featuring an integrated flange (a flat, circular base) that provides enhanced load distribution and improved pull-out resistance. They are designed to create durable, high-strength threads in soft or thin materials (e.g., aluminum, plastic, or sheet metal) where standard threading would fail. The flange acts as a bearing surface, preventing the insert from being pulled through the host material under tension.

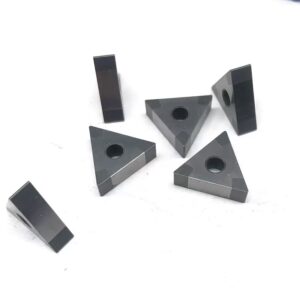

Specifications of Flanged Threaded Inserts

1. Material

Stainless Steel (304, 316 – corrosion-resistant for harsh environments).

Carbon Steel (Grade 8 – high strength, often zinc-plated).

Aluminum (lightweight, non-magnetic applications).

Brass (electrical/thermal conductivity, corrosion resistance).

2. Surface Treatment

Zinc Plating (anti-corrosion, general-purpose use).

Black Oxide (wear resistance, mild corrosion protection).

Passivation (for stainless steel, enhances corrosion resistance).

Nickel Plating (high corrosion & chemical resistance).

3. Common Specifications

Thread Sizes: M3–M24 (metric), #4–1″ (UNC/UNF).

Flange Types:

Round Flange (uniform load distribution).

Hex Flange (prevents rotation during installation).

Countersunk Flange (flush mounting for smooth surfaces).

Installation Methods:

Press-in (for plastics/soft metals).

Threaded (pre-installed with internal/external threads).

Heat/Ultrasonic (for thermoplastics).

4. Applications

자동차 (engine components, chassis mounts).

Aerospace (lightweight panel fastening).

전자 제품 (PCB mounts in high-vibration devices).

Industrial Machinery (motor mounts, gearbox housings).

Consumer Goods (furniture, plastic enclosures).

Excellent Case: Electric Vehicle (EV) Battery Housing Assembly

Challenge

An EV manufacturer needed a high-strength, vibration-resistant solution to secure battery module housings made of thin aluminum sheets. Standard screws were stripping threads due to thermal cycling and road vibrations, risking electrical failures.

Solution

Flanged Threaded Inserts (Stainless Steel 316, M8, Hex Flange) were installed into the aluminum battery trays.

Installation Process:

Precision holes were punched in the aluminum sheets.

Inserts were press-fit and swaged, with the flange distributing load across the sheet.

Torque-resistant bolts secured the battery modules, with thread-locking adhesive.

Results

✔ Zero Thread Stripping – Withstood 10,000+ thermal cycles (-30°C to 85°C).

✔ 30% Faster Assembly – Hex flanges allowed tool-free anti-rotation during bolt tightening.

✔ Weight Savings – Eliminated the need for reinforcing plates, reducing housing weight by 15%.

Industry

Electric Vehicles (High-Voltage Battery Systems)

Why Use Flanged Threaded Inserts?

✅ Pull-Out Resistance – Flange distributes load, preventing material deformation.

✅ Vibration Proof – Ideal for dynamic loads (e.g., motors, vehicles).

✅ Material Versatility – Works in metals, plastics, and composites.

✅ Corrosion Resistant – Stainless steel options for outdoor/chemical exposure.

상품평

아직 상품평이 없습니다.