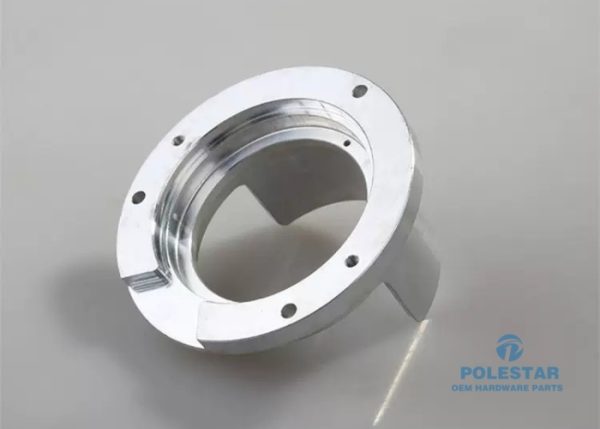

Small CNC machining Versatile Metals Plastics Composites with High Precision

Small CNC machining Versatile Metals Plastics Composites with High Precision

- 설명

- 상품평 (0)

설명

Common Materials for Small CNC Machining

Metals:

Aluminum (e.g., 6061, 7075) – Lightweight, corrosion-resistant, easy to machine.

Stainless Steel (e.g., 304, 316) – Durable, corrosion-resistant, harder to machine.

Brass – Excellent machinability, good for precision parts.

Copper – High thermal/electrical conductivity, softer metal.

Titanium – Strong, lightweight, but difficult to machine.

Mild Steel – Affordable, widely used for industrial parts.

Plastics:

ABS – Tough, impact-resistant, good for prototypes.

Nylon – Wear-resistant, used for gears and bearings.

POM (Delrin) – Low friction, high stiffness.

PTFE (Teflon) – Chemical-resistant, low friction.

Polycarbonate – Transparent, impact-resistant.

PEEK – High-performance, heat-resistant.

Other Materials:

Wood – Used for decorative or prototyping purposes.

Composites (e.g., carbon fiber, G10) – Lightweight and strong.

Common CNC Machining Methods for Small Parts

Small CNC machining typically involves:

Milling

Uses rotating cutting tools to remove material.

Ideal for complex 3D shapes, slots, and pockets.

Common for metals, plastics, and composites.

Turning (Lathe Work)

Rotates the workpiece while a cutting tool shapes it.

Best for cylindrical parts like shafts, bushings, and screws.

Drilling & Tapping

Creates precise holes and threads.

Used for fasteners and assembly components.

Wire EDM (Electrical Discharge Machining)

Uses electrical sparks to cut conductive materials.

Suitable for ultra-precise, intricate metal parts.

Laser Cutting & Engraving

Used for thin metals, plastics, and wood.

Good for detailed engravings and flat parts.

Swiss Machining

Specialized for tiny, high-precision parts (e.g., medical devices).

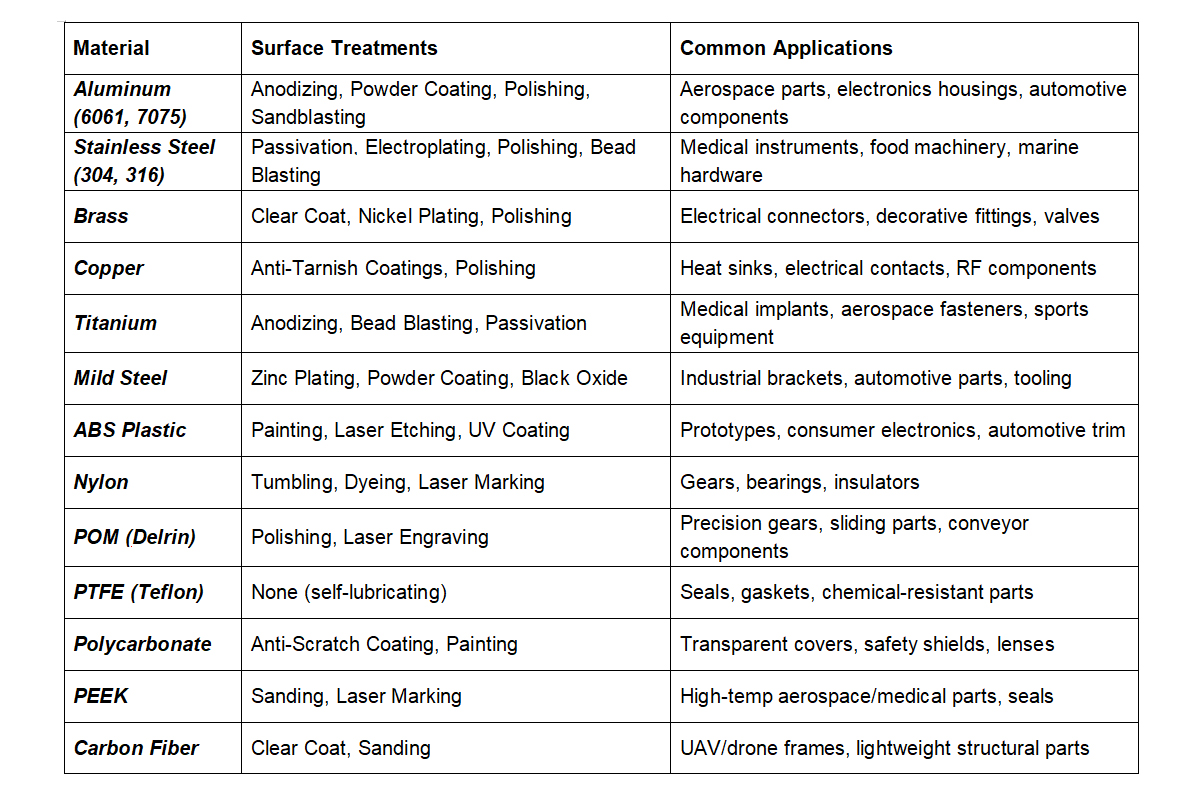

Materials, Surface Treatments & Applications

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

의료 및 치과: 수술 도구, 이식형 장치, 마이크로 패스너.

전자 제품 : 마이크로 커넥터, 센서 하우징, PCB 마운트.

항공우주 및 방위: 경량 브래킷, 드론 부품, 특수 패스너.

자동차: 연료 분사 부품, 맞춤형 패스너, 전기차 부품.

왜 우리를 선택해야 할까요?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

상품평

아직 상품평이 없습니다.