316 Stainless Steel Spacers in Industrial Applications Excellent Weldability & Machinability

0 out of 5

316 Stainless Steel Spacers in Industrial Applications Excellent Weldability & Machinability

카테고리: 금속 스페이서

- 설명

- 상품평 (0)

설명

316 Stainless Steel Spacers in Industrial Applications Excellent Weldability & Machinability

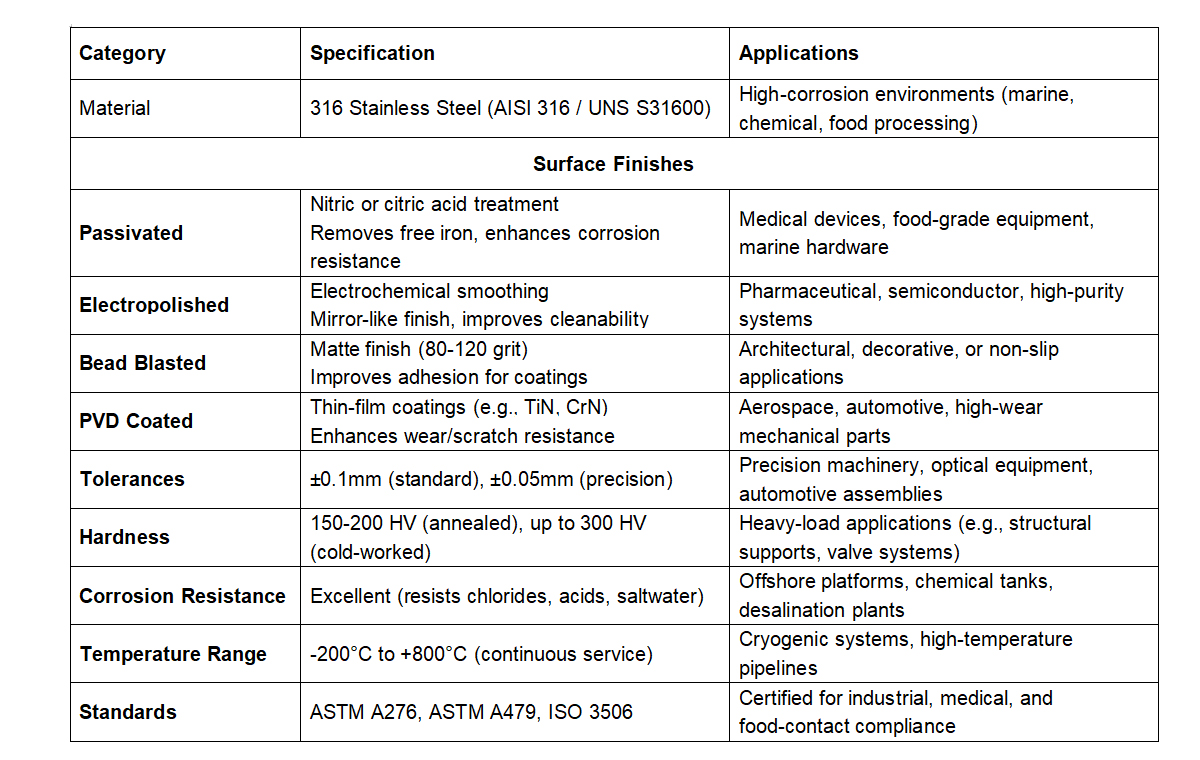

316 Stainless Steel Spacers Surface Finishes and Applications

Polestar Metal: High-Performance 316 Stainless Steel Spacers in Industrial Applications

Industry: Marine Engineering

Application: Corrosion-Resistant Spacers for Piping Systems

Challenge:

A chemical processing plant required durable spacers to maintain precise alignment in high-pressure piping systems exposed to corrosive chemicals, saltwater, and extreme temperatures. Traditional carbon steel spacers were failing due to rust and pitting, leading to frequent maintenance and downtime.

Solution:

Polestar Metal switched to 316 stainless steel spacers , known for their:

Superior corrosion resistance (due to molybdenum content)

High strength & durability in harsh environments

Excellent weldability & machinability for custom fittings

Results:

Extended lifespan – 316 spacers lasted 3x longer than carbon steel alternatives.

Reduced maintenance costs – Fewer replacements and downtime.

Improved safety – No risk of spacer failure in critical systems.

Conclusion:

316 stainless steel spacers provide long-term reliability, cost savings, and performance in demanding environments, making them a top choice for industries requiring corrosion resistance and structural integrity.

Key Advantages of 316 Stainless Steel Spacers

Versatility – Adaptable to multiple finishes for specific needs.

Durability – Performs in extreme conditions (chemical, thermal, mechanical stress).

Compliance – Meets FDA, EU, and ISO standards for hygiene/safety.

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

의료 및 치과: 수술 도구, 이식형 장치, 마이크로 패스너.

전자 제품 : 마이크로 커넥터, 센서 하우징, PCB 마운트.

항공우주 및 방위: 경량 브래킷, 드론 부품, 특수 패스너.

자동차: 연료 분사 부품, 맞춤형 패스너, 전기차 부품.

왜 우리를 선택해야 할까요?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

상품평

아직 상품평이 없습니다.