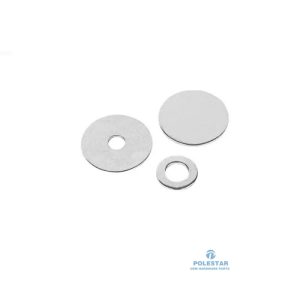

Customized Flange Washer Round Metal Coated 4 Inch Flange Washers CNC Turning Machining Part

0 out of 5

Customized Flange Washer Round Metal Coated 4 Inch Flange Washers CNC Turning Machining Part

カテゴリー: Machined Washer

タグ: 2 flange washer, 8 flange washer, CNC machined washer, CNC Machining Washer, cnc turning washers, flange washer, flange washers, m12 flange washer, machined washer, machined washers, metal flange washer, plastic flange washer, pump flange washer, round washers, steel flange washer

- 説明

- レビュー (0)

説明

What is a Flange Washer?

A flange washer (also called a shoulder washer or flanged spacer) is a type of washer with an extended rim (flange) around its central hole. This design provides a larger bearing surface, improving load distribution and preventing fastener heads or nuts from sinking into soft materials. Flange washers are commonly used in applications requiring vibration resistance, insulation, or reinforcement of thin panels.

Specifications of Flange Washer

Material:

Metal:

Carbon steel (Grade 1018, A36)

Stainless steel (304, 316 for corrosion resistance)

Aluminum (lightweight applications)

Non-Metal:

Nylon (electrical insulation, lightweight)

PTFE/Teflon (chemical & heat resistance)

Rubber (dampening vibrations)

Surface Treatment:

Zinc plating (anti-rust)

Hot-dip galvanizing (outdoor/industrial use)

Black oxide coating(durability & aesthetics)

Passivation (stainless steel corrosion protection)

Common Sizes & Dimensions:

Inner Diameter (ID): 1/8″ to 1″ (or custom)

Outer Diameter (OD): 0.5″ to 3″

Flange Thickness: 1mm to 6mm

Overall Height: 2mm to 20mm

Applications

Automotive & Aerospace: Securing panels, vibration dampening.

Electronics: Insulating circuit boards, protecting thin PCBs.

Construction: Reinforcing drywall, roofing, or composite panels.

HVAC & Plumbing: Sealing pipe flanges, reducing leaks.

Furniture Assembly: Preventing screw heads from pulling through particleboard.

Excellent Case: Automotive Wiring Harness Fixing

Scenario:

In electric vehicle (EV) battery packs, wiring harnesses must be securely fastened to metal frames without short-circuiting. Standard washers risk damaging wires or allowing vibrations to loosen connections.

Solution:

Nylon flange washers are placed under screw heads when attaching cable clips to the frame. The flange distributes pressure, while the nylon body:

Insulates the metal screw from live wires.

Absorbs vibrations from road movement.

Prevents wear on wire insulation.

Result:

Enhanced safety by eliminating electrical shorts.

Reduced maintenance from vibration-induced loosening.

Longer harness lifespan due to protected wiring.

Why Choose Flange Washers?

Versatility: Metal for strength, plastic for insulation.

Cost-Effective: Prevents damage to expensive components.

Easy Installation: No additional steps vs. standard washers.

レビュー

レビューはまだありません。