Threaded Inserts for Aluminum Bolt Threaded Inserts Threaded Inserts for Metal

Threaded Inserts for Aluminum Bolt Threaded Inserts Threaded Inserts for Metal

Categoria: Inserti filettati

Tags: 3/8 screw threaded inserts, bolt threaded inserts, Brass Threaded Inserts, heavy duty threaded inserts, m3 threaded inserts, m6 threaded inserts, m8 threaded inserts, metal threaded inserts for alunimum, screw threaded inserts, self tapping threaded inserts, stainless threaded insertsed, threaded insert, threaded inserts, threaded inserts brass, wire threaded inserts

- Descrizione

- Recensioni (0)

Descrizione

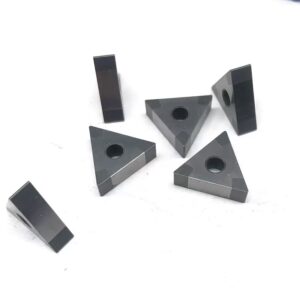

What Are Threaded Inserts for Aluminum?

Threaded inserts for aluminum are precision fastening components engineered to create durable, high-strength threaded connections in aluminum alloys. They address aluminum’s softness and low thread fatigue resistance, providing reliable threads that withstand repeated assembly cycles and vibration.

Threaded Inserts for Aluminum: Specifications

1. Material

Stainless Steel (304/316): Optimal corrosion resistance for marine/aerospace

Carbon Steel (Grade 8): High tensile strength for structural applications

Aluminum Bronze (C95400): Superior galling resistance for high-temp use

Titanium (Grade 5): Ultimate strength-to-weight ratio

2. Surface Treatment

Hard Anodizing: 50+ micron thickness for extreme wear resistance

Nickel-Teflon® Coating: Dry lubricant properties (μ<0.2)

Geomet® Coating: Anti-seize performance to 1000°C

Silver Plating: Electrical conductivity for grounding applications

3. Common Specifications

Thread Range: M3-M24 (metric), #6-1″ (UNC/UNF)

Installation: Keysert®, Rivetnut®, or helical coil systems

Special Features: Locking flute designs for vibration resistance

Standards: NASM 33537, MS 21206, ISO 15480

4. Applications

Aerospace: Airframe structural connections

EV Battery Packs: High-current busbar connections

Military Optics: Vibration-proof sight mounts

Marine: Saltwater-exposed hull components

Excellent Case: Helicopter Rotor Blade Retention System

Challenge:

A helicopter OEM experienced thread pull-out failures in 7075-T6 aluminum rotor mounts after 800 flight hours, requiring premature blade replacements.

Solution:

Installed titanium thread inserts (M10x1.5, hard anodized) using Keysert® technology:

Fatigue Life: Achieved 5,000+ stress cycles (MIL-STD-1312-21)

Corrosion Protection: Passed 1,000hr salt fog testing

Weight Savings: 40% lighter than steel alternatives

Results:

Extended service interval from 800 to 5,000 flight hours

Reduced unscheduled maintenance by 72%

Achieved FAA AC 29-2C compliance

Key Advantages

✔ 8X Higher Pull-Out Strength vs. direct aluminum threads

✔ Thermal Stability: Maintains clamp load from -65°F to +350°F

✔ EMI Shielding: Optional conductive coatings available

Recensioni

Ancora non ci sono recensioni.