Aluminum Stamped Parts Sheet Metal Fabrication Parts CNC Machined Components

Aluminum Stamped Parts Sheet Metal Fabrication Parts CNC Machined Components

Categoria: Piccola lavorazione CNC

Tags: aluminum stamped parts, auto sheet metal parts, brass stamped parts, CNC Machined Parts, cnc machining parts, custom sheet metal parts, custom stamped metal parts, customized sheet metal parts, metal stamped parts, precision stamped parts, sheet metal parts, small cnc machined parts, small cnc machining parts, stainless steel stamped parts, stamped aluminum parts, stamped bent parts, stamped car parts, stamped metal parts manufacturer, stamped parts, stamped parts automotive, stamped plastic parts, stamped steel parts

- Descrizione

- Recensioni (0)

Descrizione

What Are Stamped Parts?

Stamped parts are precision metal components manufactured through a stamping process, where sheet metal is placed in a die and formed into specific shapes using mechanical presses. This high-volume production method creates parts with excellent dimensional accuracy, consistency, and cost efficiency, making them ideal for industries requiring mass-produced metal components.

Materials

Stamped parts are typically made from:

Cold-rolled steel (good strength and formability)

Stainless steel (corrosion-resistant for harsh environments)

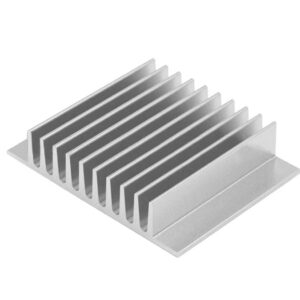

Aluminum (lightweight with good conductivity)

Copper & brass (excellent electrical/thermal properties)

High-strength alloys (for demanding structural applications)

Surface Treatments

Common finishing options include:

Powder coating (durable decorative finish)

Electroplating (zinc, nickel, or chrome for corrosion resistance)

Anodizing (for aluminum parts)

Passivation (stainless steel corrosion protection)

Galvanizing (hot-dip or electro-galvanized for steel)

Specifications

Thickness range: 0.2mm to 6mm

Tolerances: ±0.05mm to ±0.5mm depending on complexity

Maximum part size: Up to 1500mm in length

Production volume: Suitable for 10,000+ piece runs

Applications

Automotive: Brackets, chassis components, engine parts

Electronics: Connectors, shielding cans, heat sinks

Appliances: Housings, panels, internal mechanisms

Construction: HVAC components, structural brackets

Medical: Surgical instrument components, device housings

Excellent Case: Electric Vehicle Battery Enclosure

A leading EV manufacturer needed lightweight yet rigid enclosures for their next-generation battery packs. They implemented aluminum stamped parts (1.2mm thickness, anodized finish) for the protective housing.

Key Advantages:

✔ 40% weight reduction compared to steel alternatives

✔ Precision fit ensured proper thermal management spacing

✔ Corrosion-resistant anodizing protected against road salts

✔ High-volume production met demand of 50,000 units/month

The solution decreased assembly time by 25% while maintaining crash safety standards, demonstrating how stamped parts enable both performance and manufacturing efficiency in cutting-edge automotive applications.

Recensioni

Ancora non ci sono recensioni.