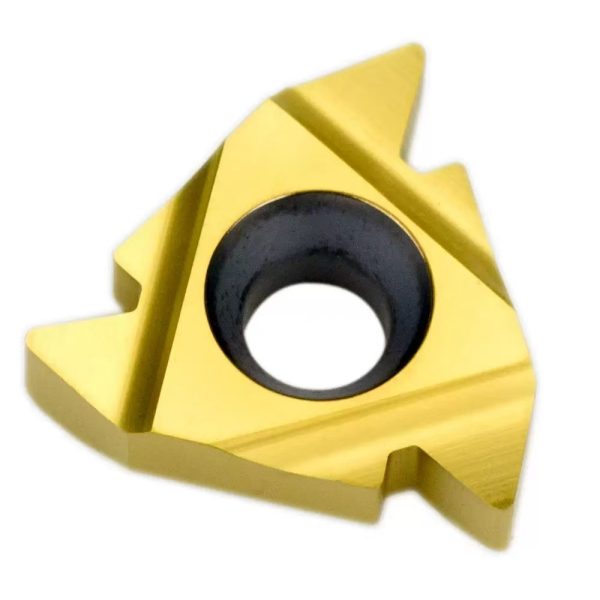

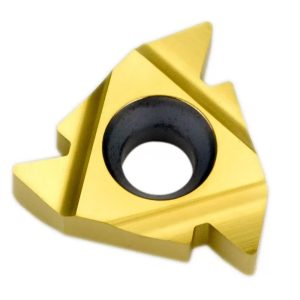

Indexable Carbide Threading Inserts for CNC Internal Turning Tools M12-M30 Metric Threads

Indexable Carbide Threading Inserts for CNC Internal Turning Tools M12-M30 Metric Threads

Categoria: Inserti filettati

Tags: 1 4 20 threaded inserts, 3/8 threaded inserts, carbide insert threading tool, carbide threading insert chart, carbide threading inserts, CNC Machined threaded insert, CNC Machined threaded inserts, m10 threaded inserts, M12 threaded inserts, M13 threaded inserts, metric threaded inserts, pcb threaded inserts, threaded inserts, threaded inserts brass, threaded inserts for metal, threaded inserts steel

- Descrizione

- Recensioni (0)

Descrizione

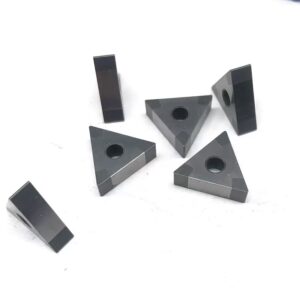

What Are Carbide Threading Inserts?

Carbide threading inserts are precision cutting tools made from tungsten carbide, designed for creating high-accuracy internal or external threads in metals, plastics, and composites. They replace traditional taps and dies, offering superior wear resistance and thread quality in CNC machining and mass production.

Carbide Threading Inserts: Specifications

1. Material

Micrograin Tungsten Carbide (K10/K20): 90-94 HRA hardness for steel/iron

Submicron Carbide (Ultra-Fine Grain): For aerospace alloys (Ti, Inconel)

Coated Carbide (TiAlN/AlCrN): 3X tool life vs. uncoated

2. Surface Treatment

PVD Coating (TiN/TiCN): Reduces friction, resists built-up edge

CVD Diamond Coating: For abrasive composites (CFRP, ceramics)

Laser-Textured Flutes: Chip evacuation optimization

3. Common Specifications

Thread Standards: Metric (M1–M30), UNC/UNF (#0–1″), NPT/BSPT

Insert Geometry: Full-profile, partial-profile, multi-tooth

Tolerance Class: 4H/6H (internal), 4g/6g (external)

Coolant Compatibility: Through-coolant designs available

4. Applications

Automotive: High-volume engine block threading

Aerospace: CRES & titanium fastener holes

Oil & Gas: API threads on drill collars

Medical: Micro-threads in bone screws

Excellent Case: EV Motor Housing Production

Challenge:

An EV manufacturer struggled with tap breakage when threading 500+ aluminum motor housings daily. Conventional HSS taps lasted only 200 holes before chipping.

Solution:

Deployed TiAlN-coated carbide inserts (M8x1.25 full-profile):

Speed: 80 m/min cutting vs. 20 m/min with HSS

Tool Life: 5,000+ holes per edge (25X improvement)

Surface Finish: Ra 0.8μm, eliminating secondary polishing

Results:

Reduced threading cost per unit by 62%

Achieved ±0.02mm pitch diameter consistency

Enabled lights-out production with automated tool changers

Key Advantages

✔ Thread Quality – Maintains ISO 965 class 6H tolerance after 10K cycles

✔ Versatility – Interchangeable inserts for left/right-hand threads

✔ Cost Savings – Indexable design uses all cutting edges

Recensioni

Ancora non ci sono recensioni.