Custom-Molded Teflon Shoulder Washer Nylon PTFE Shoulder Washers

Custom-Molded Teflon Shoulder Washer Nylon PTFE Shoulder Washers

- Descrizione

- Recensioni (0)

Descrizione

Custom-Molded Teflon Shoulder Washer Nylon PTFE Shoulder Washers

1. Material Types of Teflon Shoulder Washer

Nylon 6/6 (Most common, high strength, chemical resistance)

Nylon 4/6 (Higher heat resistance)

Acetal (POM) (Low friction, dimensional stability)

Polypropylene (PP) (Chemical/UV resistance, lightweight)

PTFE (Teflon®) (Non-stick, extreme temperature tolerance)

PVC (Cost-effective, electrical insulation)

Polycarbonate (PC) (Impact resistance, transparency options)

PEEK (High-performance, aerospace/medical grade)

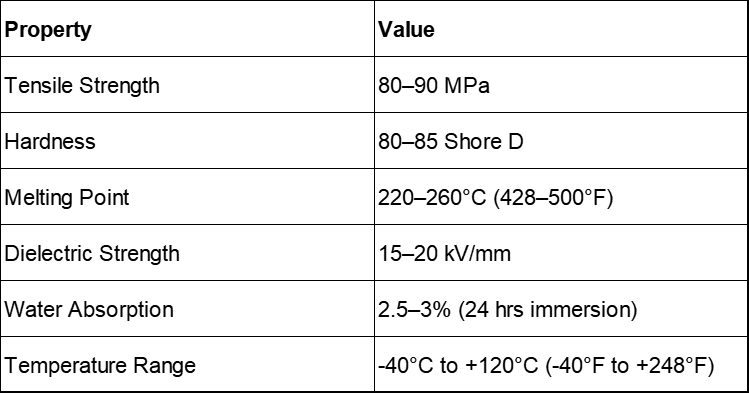

Material Properties (Nylon 6/6)

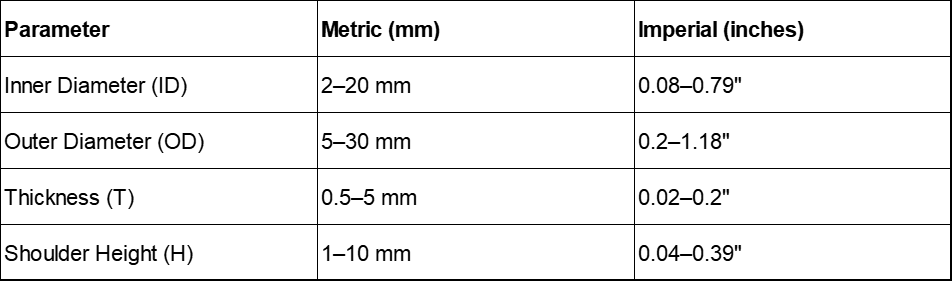

2. Standard Sizes (Metric & Imperial)

Inner Diameter (ID): 2mm–20mm (0.08″–0.79″)

Outer Diameter (OD): 5mm–30mm (0.2″–1.18″)

Shoulder Height: 1mm–10mm (0.04″–0.39″)

Thickness (Shank): 0.5mm–5mm (0.02″–0.2″)

(Custom sizes available for OEM orders.)

3. Colors

Black (Most common, UV-stabilized options)

Natural/White (Nylon, Acetal)

Gray (PEEK, PTFE)

Translucent (Polycarbonate, PP)

Custom Colors (Dyeable for branding/identification)

4. Key Applications

Electronics: PCB insulation, grounding washers, wire routing.

Automotive: Vibration dampening, fastener isolation.

HVAC/Plumbing: Pipe supports, corrosion-resistant spacers.

Medical Devices: Sterilizable, non-toxic components.

Industrial Machinery: Wear-resistant bushings, pivot points.

Renewable Energy: Solar panel mounts, wind turbine assemblies.

5. Certifications & Properties

UL94 V-0/V-2 (Flame retardant)

RoHS/REACH Compliant

Dielectric Strength: 500V–1kV (Nylon/Acetal)

Temperature Range:

Nylon: -40°C to +120°C (-40°F to +248°F)

PEEK: -60°C to +260°C (-76°F to +500°F)

Excellent Case: Teflon Shoulder Washer in Chemical Processing Equipment

Application: Sealing and Isolating Flange Connections in a Corrosive Environment

Problem: A chemical plant needed to secure flange joints in a pipeline carrying highly corrosive acids (e.g., sulfuric acid, hydrochloric acid) . Standard metal washers posed several risks:

Galvanic corrosion when dissimilar metals contacted acidic fluids.

Seal degradation due to chemical attack on rubber or plastic gaskets.

Fretting wear from pipe vibrations, leading to leaks.

Solution: Teflon (PTFE) Shoulder Washer

A Teflon shoulder washer was installed between stainless steel bolts and the flange face to:

✅ Prevent Corrosion – PTFE is chemically inert, resisting even concentrated acids and solvents.

✅ Reduce Friction & Wear – The low-friction surface minimized galling and fretting damage.

✅ Act as a Seal – The washer’s shoulder provided an additional barrier against fluid leakage.

✅ Electrical Isolation – PTFE’s non-conductive properties prevented stray current corrosion.

Result:

Zero leaks or corrosion observed after 2+ years of continuous operation.

Eliminated maintenance downtime caused by washer/gasket replacement.

Extended flange lifespan by preventing metal-to-metal contact degradation.

Key Takeaway:

Teflon shoulder washers excel in harsh chemical, high-purity, or electrically sensitive environments . Other ideal applications include:

Pharmaceutical systems (non-reactive, FDA-compliant material).

Semiconductor manufacturing (ultra-clean, particle-free performance).

Marine/offshore (resisting saltwater and cathodic disbondment).

Recensioni

Ancora non ci sono recensioni.