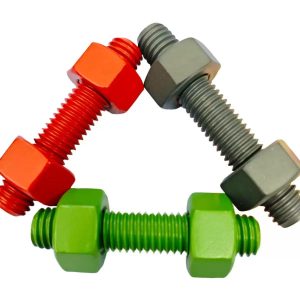

Class 10.9 Steel Hardened Step Studs Double End Threaded Stepped Studs

Class 10.9 Steel Hardened Step Studs Double End Threaded Stepped Studs

- Deskripsi

- Ulasan (0)

Deskripsi

What Are Step Studs?

Step studs are specialized threaded fasteners designed with multiple diameter steps along their length. These studs typically feature varying thread sizes or unthreaded sections, allowing them to serve as adapters or connectors in assemblies where different bolt sizes or mounting configurations are required. They are widely used in industries where precise alignment, vibration resistance, and multi-component fastening are essential.

Materials

Step studs are manufactured from a variety of materials to meet different mechanical and environmental requirements. Common materials include:

Carbon Steel – Economical and strong, suitable for general-purpose applications.

Alloy Steel – Offers higher strength and durability, often heat-treated for enhanced performance.

Stainless Steel (304/316) – Provides excellent corrosion resistance, ideal for marine, chemical, and food-processing industries.

Brass – Used in electrical and plumbing applications due to its anti-corrosive and conductive properties.

Titanium – Lightweight yet extremely strong, used in aerospace and high-performance engineering.

Surface Treatments

To improve durability and functionality, step studs undergo various surface treatments, such as:

Zinc Plating – Enhances corrosion resistance and provides a shiny finish.

Hot-Dip Galvanizing – Offers a thick protective layer for harsh environments.

Black Oxide – Improves wear resistance and reduces light reflection.

Nickel or Chrome Plating – Adds aesthetic appeal and extra corrosion protection.

Phosphate Coating – Improves lubricity and rust resistance in automotive applications.

Specifications

Thread Types: Metric (M), Unified (UNC/UNF), or custom threads.

Diameter Steps: Common combinations include M6-M8, M8-M10, ¼”-⅜”, etc.

Length Variations: Ranging from short adapter studs (20mm) to long stepped studs (200mm+).

Tolerance Grades: Precision-machined to meet ISO, DIN, or ANSI standards.

Applications

Automotive: Engine mounts, suspension systems, and gearbox assemblies.

Machinery & Equipment: Connecting mismatched components in heavy machinery.

Construction: Structural fastening where different bolt sizes are needed.

Aerospace: Lightweight yet high-strength fastening in aircraft components.

Electronics: Securing circuit boards or mounting hardware with varying thread requirements.

Excellent Case: Step Studs in Automotive Turbocharger Systems

A prime example of step studs’ effectiveness is in turbocharger installations for high-performance vehicles. Turbochargers require secure mounting between the exhaust manifold and the turbo housing, often involving different thread sizes due to thermal expansion and vibration concerns.

Implementation:

Material: High-grade stainless steel (AISI 316) to withstand extreme heat and corrosion.

Design: One end threads into the manifold (M10x1.5), while the other (M8x1.25) secures the turbo flange.

Benefits:

Ensures a rigid connection, reducing turbo lag and vibration-induced failures.

Simplifies assembly by eliminating the need for multiple adapters.

Enhances longevity due to superior heat and corrosion resistance.

This application demonstrates how step studs provide reliability, efficiency, and adaptability in demanding mechanical environments.

Ulasan

Belum ada ulasan.