Custom Small CNC Machining Hardware Parts Aluminum Stainless Steel Parts Lathe Turning

Custom Small CNC Machining Hardware Parts Aluminum Stainless Steel Parts Lathe Turning

- Deskripsi

- Ulasan (0)

Deskripsi

What are CNC Machining Hardware Parts?

CNC machining hardware parts are precision-engineered components produced using computer numerical control (CNC) technology to ensure high accuracy, tight tolerances, and repeatability. These parts include brackets, fasteners, hinges, knobs, and custom connectors used across industries where reliability and dimensional precision are critical.

Materials of Hardware Parts

Aluminum (6061, 7075) – Lightweight, corrosion-resistant, ideal for aerospace and consumer electronics.

Stainless Steel (304, 316) – High strength and rust-proof for medical and marine applications.

Brass (C360, C260) – Excellent machinability and aesthetic appeal for decorative fixtures.

Titanium (Grade 2, Grade 5) – Biocompatible and strong for medical implants and high-performance engineering.

Plastics (PEEK, Delrin, Nylon) – Non-conductive, lightweight, and chemical-resistant for electrical and automotive uses.

Surface Treatments

Anodizing (Aluminum) – Enhances corrosion resistance and allows color customization.

Electropolishing (Stainless Steel) – Improves smoothness and cleanability for medical parts.

Powder Coating – Durable, scratch-resistant finish for outdoor and industrial components.

Zinc Plating (Steel) – Basic rust protection for cost-effective hardware.

Brushing/Polishing – Decorative finish for visible components in furniture and appliances.

Key Specifications

Tolerances: ±0.005mm (for high-precision applications).

Thread Types: Metric, UNC/UNF, or custom threading.

Size Range: 1mm–500mm (for miniature screws to structural brackets).

Load Capacity: Varies by material (e.g., aluminum brackets up to 200kg, steel up to 1000kg).

Applications of Hardware Parts

Furniture Manufacturing – CNC-machined hinges, drawer slides, and table brackets.

Aerospace – Lightweight aluminum fittings and titanium fasteners.

Medical Devices – Surgical instrument components and implantable hardware.

Automotive – Engine mounts, sensor housings, and interior trim clips.

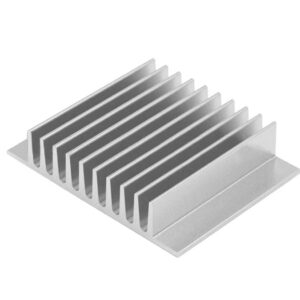

Electronics – Heat sinks, enclosures, and connector pins.

Excellent Case: High-End Modular Furniture System

Challenge:

A luxury furniture brand needed CNC-machined aluminum connectors for a modular shelving system requiring:

Seamless, tool-free assembly

Sleek, visible hardware with premium finish

Load-bearing capacity of 50kg per joint

Solution:

Precision CNC-machined 6061-T6 aluminum brackets with:

Hidden dovetail joints for smooth, screw-free assembly.

Brushed & clear-anodized finish for scratch resistance and modern aesthetics.

Integrated alignment pins (±0.1mm tolerance) ensuring perfect fit.

Results:

30% faster assembly compared to traditional screwed joints.

Zero customer returns due to misalignment or loosening.

Featured in premium design magazines, boosting brand prestige.

Ulasan

Belum ada ulasan.