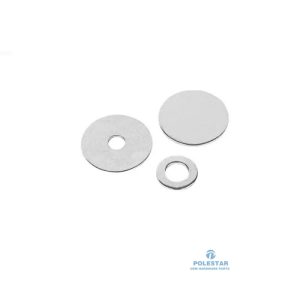

Customized Tapered Serrated Lock Washer DIN6798 Conical External Tooth Washers

Customized Tapered Serrated Lock Washer DIN6798 Conical External Tooth Washers

- Deskripsi

- Ulasan (0)

Deskripsi

What is a Tapered Serrated Lock Washer?

A tapered serrated lock washer is a specialized type of washer designed with a conical (tapered) shape and serrated teeth on either the inner or outer circumference. Unlike flat washers, this design provides superior resistance to loosening caused by vibrations, thermal expansion, or dynamic loads. The serrations “bite” into the mating surface and fastener, creating a locking effect, while the tapered shape adds spring tension to maintain clamping force.

These washers are commonly used in high-stress applications where traditional flat or spring washers may fail. They come in two main types:

External-toothed: Teeth on the outer edge for better grip on larger surfaces.

Internal-toothed: Teeth on the inner edge for enhanced locking on smaller fasteners47.

Materials of Tapered Serrated Lock Washers

To suit various industrial needs, these washers are made from durable materials, including:

Carbon Steel (e.g., 65Mn, 50#) – High strength and cost-effective for general applications8.

Stainless Steel (e.g., 304, 316, 420) – Excellent corrosion resistance for marine, chemical, and food industries68.

Alloy Steel – Heat-treated for extreme stress resistance in heavy machinery.

Brass & Bronze – Used in electrical applications for conductivity and corrosion resistance6.

Inconel & Titanium – For aerospace and high-temperature environments.

Surface Treatments

To enhance durability and performance, tapered serrated lock washers undergo various surface treatments:

Zinc Plating – Provides rust resistance for carbon steel washers8.

Black Oxide – Improves corrosion resistance and reduces glare.

Phosphate Coating – Enhances wear resistance and lubricity8.

Passivation (for Stainless Steel) – Removes free iron particles to prevent corrosion6.

Electropolishing – Smoothens surfaces for better fatigue resistance.

Specifications & Standards

Tapered serrated lock washers follow international standards, ensuring compatibility and reliability:

DIN 6798A – The most common standard for external-toothed washers28.

IS 5556A / IS 55568 – Indian standards for industrial applications7.

Size Range – From M1.6 (tiny electronics) to M36 (heavy machinery)78.

Load Capacity – Varies by material and tooth design, with stainless steel offering high fatigue resistance.

Applications of Tapered Serrated Lock Washers

These washers are critical in industries where vibration resistance and secure fastening are essential:

Automotive & Aerospace – Engine mounts, landing gear, and exhaust systems to prevent bolt loosening.

Heavy Machinery – Presses, hydraulic systems, and mining equipment under extreme vibrations.

Construction & Infrastructure – Bridges, steel frameworks, and seismic-resistant structures.

Electrical & Electronics – Grounding connections and circuit breakers for stable conductivity.

Oil & Gas – Pipeline flanges and offshore rigs exposed to corrosive environments6.

Excellent Case: Tapered Serrated Washers in Wind Turbine Blade Connections

Wind turbines endure constant vibrations, wind forces, and thermal cycles, making bolt security crucial.

Challenge: Blade root joints must remain tightly fastened despite dynamic loads to prevent catastrophic failure.

Solution: Engineers use stainless steel DIN 6798A external-toothed tapered serrated washers in these joints. The serrations bite into the flange, while the tapered design maintains clamping force even under stress relaxation.

Results:

Zero Bolt Loosening – Ensures structural integrity over decades of operation.

Reduced Maintenance Costs – Eliminates frequent retightening.

Enhanced Safety – Prevents blade detachment, a critical factor in wind farm reliability.

This application highlights how tapered serrated lock washers are indispensable in renewable energy, where failure is not an option.

Ulasan

Belum ada ulasan.