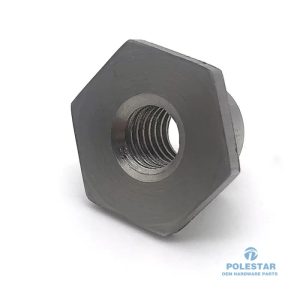

3/8 5/8 Cap Nut Stainless Steel Cap Nuts For Light Fixture

3/8 5/8 Cap Nut Stainless Steel Cap Nuts For Light Fixture

- Deskripsi

- Ulasan (0)

Deskripsi

A cap nut, also known as a dome nut or acorn nut, is a type of fastener with a domed or capped end that covers the threads of a bolt or screw. This design not only provides a finished and aesthetically pleasing appearance but also protects the exposed threads from dirt, debris, moisture, and other environmental factors, preventing corrosion and damage. Additionally, it can help reduce the risk of injury from sharp or protruding threads.

Materials

Steel : It is one of the most commonly used materials. Steel cap nuts offer high strength and durability, suitable for a wide range of applications. They can be further classified into carbon steel and alloy steel, with alloy steel providing enhanced mechanical properties such as higher tensile strength and better corrosion resistance.

Stainless Steel : Known for its excellent corrosion resistance, stainless – steel-cap-nuts are ideal for applications in harsh environments, such as marine, chemical, and food – processing industries. They are also aesthetically pleasing and require minimal maintenance.

Brass : Brass cap-nuts have good electrical conductivity and are often used in electrical and electronic applications. They also have a relatively attractive appearance and are resistant to corrosion in some non – aggressive environments.

Aluminum : Aluminum cap nuts are lightweight and have good corrosion resistance. They are commonly used in applications where weight is a critical factor, such as in the aerospace and automotive industries.

Surface Treatments

Zinc Plating : This is a common surface treatment for steel cap nuts. Zinc plating provides a protective layer that helps prevent corrosion. It can be further classified into different types, such as clear zinc plating (providing basic corrosion protection) and yellow zinc plating (offering better corrosion resistance).

Hot – Dip Galvanizing : A more heavy – duty corrosion – protection method, hot – dip galvanizing involves coating the cap-nut with a thick layer of zinc by immersing it in molten zinc. This treatment is suitable for outdoor or highly corrosive environments.

Chrome Plating : Chrome – plated cap-nuts have a shiny and decorative appearance. They also offer good corrosion resistance and are often used in applications where aesthetics are important, such as in automotive trim or furniture.

Black Oxide Coating : This treatment gives the cap nut a black finish. It provides some degree of corrosion resistance and also helps reduce glare. Black oxide – coated cap nuts are commonly used in military and industrial applications.

Specifications

Size : In a variety of sizes, which are typically specified by the thread diameter (e.g., M3, M4, M5 for metric sizes; #4 – 40, #6 – 32, 1/4 – 20 for imperial sizes) and the thread pitch. The height and outer diameter of the cap nut also vary depending on the size and design.

Thread Type : Common thread types include metric threads (ISO metric) and imperial threads (UNC, UNF in the United States). Metric threads are widely used in most countries around the world, while imperial threads are still prevalent in some industries, especially in the United States.

Grade : The grade indicates its strength. For example, in steel-cap-nuts, grades such as 8.8, 10.9, and 12.9 represent different levels of tensile strength and hardness. Higher – grade cap-nuts are suitable for applications with higher load – bearing requirements.

Application Areas

Automotive Industry : Used in various parts of a vehicle, such as on engine components, suspension systems, and body panels. They not only provide a secure fastening but also contribute to the overall appearance of the vehicle.

Construction Industry : In construction, they are used to fasten structural elements, such as steel beams and columns. They are also used in architectural applications to cover exposed bolts and provide a finished look.

Electrical and Electronics : Due to their ability to protect threads and provide an aesthetic finish, cap-nuts are used in electrical enclosures, control panels, and electronic devices.

Furniture Manufacturing : Cap nuts are used to fasten furniture components, such as legs, frames, and joints. They can enhance the appearance of the furniture and prevent damage to the threads.

Marine Industry : Given the harsh salt – water environment, stainless – steel cap nuts are commonly used in marine applications, such as on boats, ships, and offshore structures, to prevent corrosion.

Automotive Engine Assembly : When assembling an engine, cap nuts are used to secure various components, such as the valve cover. The cap nut covers the bolt threads, preventing oil and dirt from accumulating on the threads and ensuring a clean and reliable connection.

Building Facade Installation : In the installation of a building facade, cap nuts are used to fasten cladding panels to the building structure. The cap nuts not only provide a strong connection but also give the facade a smooth and finished appearance.

Electrical Cabinet : In an electrical cabinet, cap nuts are used to secure the door hinges and other components. They protect the threads from dust and moisture, ensuring the long – term reliability of the electrical connections.

Outdoor Furniture : For outdoor furniture, such as garden benches and tables, cap nuts are used to fasten the legs and frames. They prevent rusting and damage to the threads caused by exposure to the elements, extending the lifespan of the furniture.

Ulasan

Belum ada ulasan.