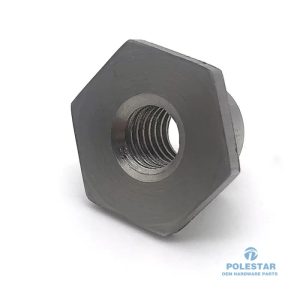

OEM Solid CNC Machined Brass Nuts Precision Threaded Connectors for Plumbing and Electronics

OEM Solid CNC Machined Brass Nuts Precision Threaded Connectors for Plumbing and Electronics

- Description

- Reviews (0)

Description

Brass nuts are internally threaded fasteners made from brass, primarily used to secure bolts or threaded rods in assemblies requiring corrosion resistance, electrical conductivity, or aesthetic appeal. Their non-magnetic and anti-sparking properties make them ideal for specialized industrial and decorative applications.

Materials

Brass nuts are typically manufactured from these brass alloys:

Free-Cutting Brass (C36000) – Excellent machinability, common for standard nuts.

Naval Brass (C46400) – Superior corrosion resistance in marine environments.

Lead-Free Brass (C27400) – Compliant with environmental regulations for plumbing.

High-Strength Brass (C38500) – Used in heavy-load applications.

Surface Treatments

To enhance functionality and appearance, brass nuts may feature:

Natural Polish – Retains brass’s golden finish for decorative uses.

Nickel Plating – Improves corrosion resistance and provides a silver appearance.

Chrome Plating – Adds durability and a reflective finish.

Lacquer Coating – Prevents tarnishing while maintaining the original brass color.

Specifications

Brass nuts are available in various standards and sizes:

Thread Types: Metric (M3-M24), UNC/UNF (e.g., #4-40 to 1″–14).

Nut Styles: Hex, square, flange, lock (nylon insert), or wing nuts.

Strength Grades: Commercial (non-rated) or ASTM B16 for mechanical applications.

Temperature Range: –20°C to 200°C (varies with alloy).

Applications

Brass nuts are widely used in:

✔ Plumbing & HVAC – Resists water corrosion in valves and pipe fittings.

✔ Electrical & Electronics – Non-magnetic and conductive for grounding systems.

✔ Marine & Offshore – Withstands saltwater exposure in boat hardware.

✔ Automotive Fuel Systems – Spark-resistant for fuel line connections.

✔ Decorative Hardware – Aesthetic choice for furniture and architectural fixtures.

Excellent Case: Marine Fuel Line Assembly

Industry: Marine Engineering

Challenge: A boat manufacturer needed corrosion-resistant fasteners for fuel line connections, where steel nuts would rust and aluminum nuts lacked strength.

Solution: Naval brass nuts (C46400) with nickel plating were used to secure fuel line joints. The brass resisted seawater corrosion, while the nickel layer prevented galvanic reaction with stainless steel bolts.

Result:

Zero corrosion after 5 years in saltwater environments.

No spark risk, enhancing safety near fuel systems.

Easy maintenance due to the nut’s anti-seizing properties.

Reviews

There are no reviews yet.