304 Stainless Steel Key Locking Thread Inserts Wire Threaded Key Insert

0 out of 5

304 Stainless Steel Key Locking Thread Inserts Wire Threaded Key Insert

Category: Threaded Inserts

Tags: 1 4 20 threaded insert, 1/2 threaded inserts, 1/4 in threaded insert, 3 8 threaded insert, 5/16 threaded inserts, key lock threaded insert, key lock threaded inserts, key locking threaded inserts, locking threaded insert, m3 threaded insert, m5 threaded inserts, m8 threaded insert, stainless steel threaded inserts, stainless threaded inserts, threaded insert, threaded insert 1 4 20, threaded insert 1/4, threaded insert 3/8, threaded insert 5/16, threaded insert m3, threaded insert m4, threaded insert metal, threaded insert stainless, threaded insert stainless steel, threaded inserts, wire threaded inserts

- Description

- Reviews (0)

Description

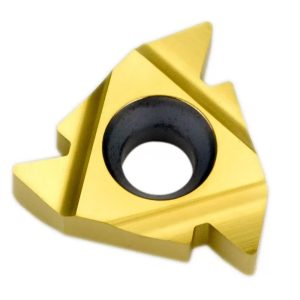

What Are Key Locking Thread Inserts?

Key Locking Thread Inserts are specialized threaded inserts designed to provide a secure, vibration-resistant fastening solution in soft or weak materials such as aluminum, plastic, or thin metals. Unlike standard helical inserts, key locking inserts feature a unique “key” or locking mechanism that prevents rotation or loosening under high stress or vibration. They are commonly used in aerospace, automotive, and industrial applications where reliability is critical.

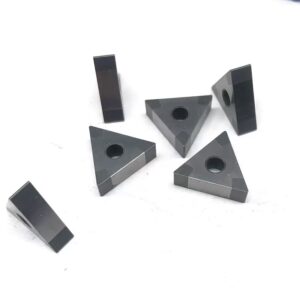

Materials

Key locking thread inserts are manufactured from high-performance materials to ensure durability and corrosion resistance. Common materials include:

Stainless Steel (304, 316, 17-7PH, 18-8): Offers excellent corrosion resistance and strength.

Carbon Steel (Grade 8, Alloy Steel): Provides high tensile strength for heavy-duty applications.

Inconel (Inconel 600, 718): Used in extreme-temperature environments, such as jet engines.

Brass & Bronze: Suitable for electrical and marine applications due to anti-corrosive properties.

Titanium (Grade 2, Grade 5): Lightweight yet strong, ideal for aerospace applications.

Surface Treatments

To enhance performance, key locking inserts often undergo surface treatments:

Passivation (Stainless Steel): Improves corrosion resistance.

Zinc Plating (Carbon Steel): Prevents rust in standard environments.

Cadmium Plating (Aerospace): Offers superior corrosion protection but is restricted in some industries.

PTFE (Teflon) Coating: Reduces friction and prevents galling in stainless steel inserts.

Black Oxide: Provides mild corrosion resistance and a non-reflective finish.

Specifications of Key Locking Thread Inserts

Key locking inserts come in various sizes and thread types, including:

Metric (M2 – M36) & Imperial (UNC, UNF, BSW, BSF)

Coarse & Fine Thread Pitches

Different Lengths (1D, 1.5D, 2D, etc.)

Internal & External Thread Configurations

Key Locking Styles (Tang, Notch, or Collar-Based Locking)

Applications

Key locking inserts are widely used in industries requiring vibration resistance and high-strength threaded solutions:

Aerospace: Engine components, landing gear, and structural assemblies.

Automotive: Transmission systems, engine blocks, and suspension parts.

Military & Defense: Firearms, armored vehicles, and missile systems.

Industrial Machinery: Heavy equipment, hydraulic systems, and robotics.

Marine & Oil/Gas: Subsea equipment, pumps, and offshore rigs.

Excellent Case: Helicopter Rotor Blade Fastening

Challenge

A leading aerospace manufacturer faced recurring issues with rotor blade attachment bolts loosening due to extreme vibrations during flight. Standard helical inserts failed to maintain torque, risking catastrophic failure.

Solution

The engineering team implemented stainless steel (17-7PH) key locking inserts with PTFE coating to prevent thread galling. The inserts were installed into the aluminum rotor hub with a tang-style locking key, ensuring zero rotation under vibration.

Results

Zero bolt loosening after 5,000+ flight hours.

Reduced maintenance costs by eliminating frequent re-torquing.

Enhanced safety for high-stress aerospace applications.

This case demonstrates how key locking thread inserts provide unmatched reliability in critical applications.

Reviews

There are no reviews yet.