Custom Machined Washer Stainless Steel Brass Aluminum Plastic Rubber

Custom Machined Washer Stainless Steel Brass Aluminum Plastic Rubber

- Description

- Reviews (0)

Description

Custom Machined Washer Stainless Steel Brass Aluminum Plastic Rubber

- Flat Washer (Plain Washer)

Description: A simple, flat disc with a central hole.

Applications:

Distributes load under bolt/nut heads.

Protects surfaces from damage.

Acts as a spacer.

Materials: Steel, stainless steel, brass, plastic.

Key Features: Low cost, widely available, basic load distribution.

- Spring Washer (Split Lock Washer)

Description: A washer with a split ring that provides spring tension.

Applications:

Prevents loosening due to vibration (e.g., automotive, machinery).

Materials: Carbon steel, stainless steel.

Key Features: Elasticity helps maintain bolt tension.

- Wave Washer

Description: A washer with a wavy shape, providing spring-like action.

Applications:

Absorbs axial loads and vibrations (e.g., electronics, bearings).

Materials: Steel, stainless steel, phosphor bronze.

Key Features: Flexible, absorbs shock and vibration.

- Belleville Washer (Conical Washer)

Description: A conical disc that acts as a high-load spring.

Applications:

High-pressure applications (e.g., valves, heavy machinery).

Materials: Alloy steel, stainless steel.

Key Features: High spring rate, compact design.

- Fender Washer

Description: A large-diameter flat washer with a small hole.

Applications:

Used in automotive (fenders), construction, and sheet metal work.

Materials: Steel, stainless steel.

Key Features: Spreads load over a wider area.

- Shoulder Washer

Description: A washer with a built-in shoulder/spacer.

Applications:

Electrical insulation or precise spacing (e.g., PCB mounting).

Materials: Nylon, PTFE, stainless steel.

Key Features: Provides insulation and alignment.

- Torque Washer

Description: A washer with tabs to prevent rotation.

Applications:

Woodworking, roofing, and structural applications.

Materials: Steel, galvanized steel.

Key Features: Prevents bolt/nut from turning.

- Countersunk Washer

Description: A washer with a tapered edge to fit countersunk screws.

Applications:

Used with flat-head screws for a flush finish (e.g., furniture, aerospace).

Materials: Steel, aluminum.

Key Features: Ensures smooth surface alignment.

- Sealing Washer

Description: A washer with a rubber or fiber gasket.

Applications:

Prevents leaks in plumbing, hydraulic systems, and automotive.

Materials: Rubber, neoprene, fiber.

Key Features: Provides a watertight or airtight seal.

- Shim Washer

Description: A thin washer for fine adjustments.

Applications:

Precise spacing in machinery and automotive alignment.

Materials: Steel, brass, plastic.

Key Features: Allows micro-adjustments in assembly.

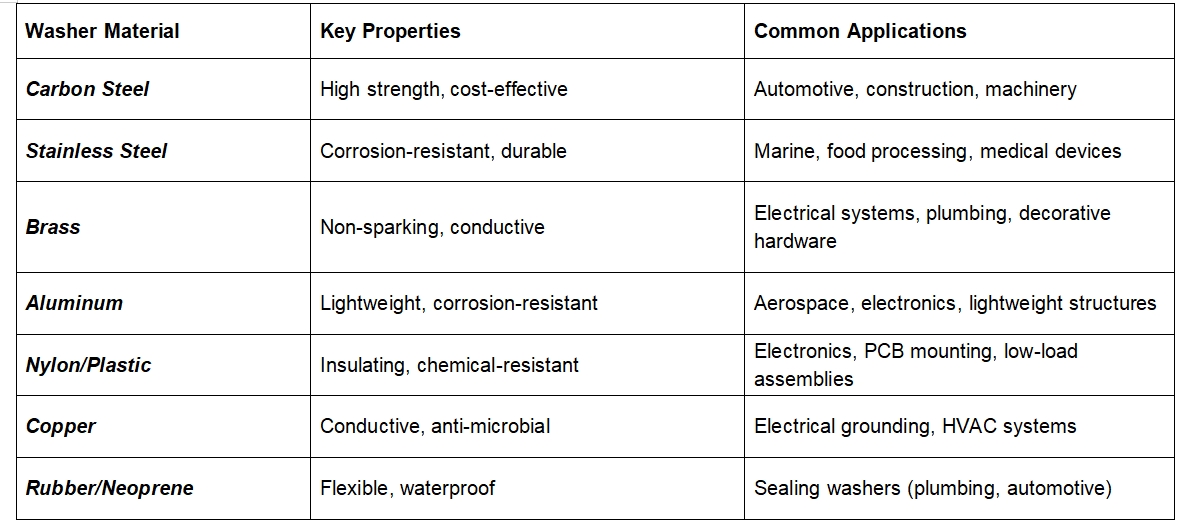

Specification of Custom Machined Washer

Additional Information of Custom Machined Washer:

Materials: Common materials include carbon steel, stainless steel, brass, nylon, and rubber depending on corrosion resistance and load requirements.

Standards: Many washers follow ISO, DIN, ANSI, or JIS standards for dimensions and performance.

Selection Criteria: Consider load, vibration, corrosion resistance, and thermal conditions when choosing a washer.

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Medical & Dental : Surgical tools, implantable devices, micro-fasteners.

Electronics : Micro-connectors, sensor housings, PCB mounts.

Aerospace & Defense : Lightweight brackets, drone components, specialty fasteners.

Automotive : Fuel injection parts, custom fasteners, EV components.

Why Choose Us?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Reviews

There are no reviews yet.