Custom Stainless Steel Eyebolts for lifting Eyebolt for Wood Concrete

Custom Stainless Steel Eyebolts for lifting Eyebolt for Wood Concrete

- Description

- Avis (0)

Description

Custom Stainless Steel Eyebolts for lifting Eyebolt for Wood Concrete

What Are Eyebolts?

Eyebolts are threaded fasteners with a circular ring (“eye”) at one end, designed for lifting, rigging, anchoring, or securing loads. They are commonly used in construction, marine, industrial, and stage rigging applications.

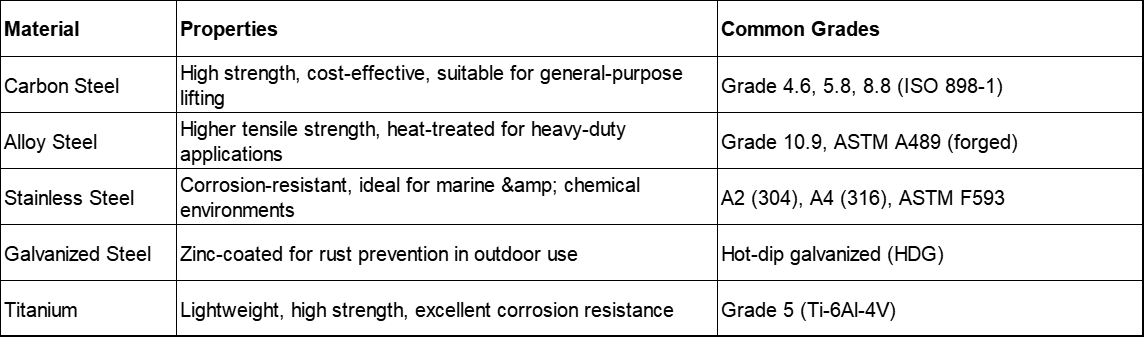

Materials of Lifting Eyebolts

Eyebolts are made from various materials based on strength and environmental requirements:

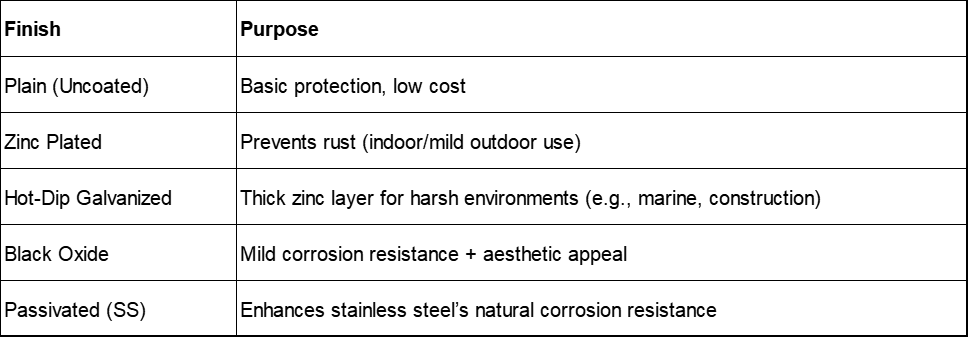

Surface Finishes

Specifications & Types

Eyebolts are categorized by design and load capacity:

A. Standard Eyebolt (DIN 580 / ISO 3266)

Thread: Metric (M6–M64) or Inch (1/4″–2″)

Load Rating:

Shoulder Type (DIN 582): For angular loads (max 45° from vertical).

Non-Shoulder Type (DIN 580): Vertical loads only.

Standards: EN 13889 (lifting), ASME B18.15 (US inch series).

B. Forged Eyebolt (Heavy-Duty)

Material: Alloy steel (ASTM A489)

Load Capacity: Up to 25,000 lbs (11,340 kg).

C. Screw Eye (Lag Eye)

Thread: Wood/masonry thread for anchoring.

Applications

Lifting & Rigging: Cranes, hoists, and material handling.

Marine: Mooring, boat tie-downs (stainless steel preferred).

Construction: Temporary anchoring for scaffolding.

Stage & Theater: Hanging lights, sound equipment.

Agriculture: Securing tarps, livestock equipment.

Case Examples

Construction Site: A hot-dip galvanized eyebolt (M20, Grade 8.8) secures a steel beam during crane lifting.

Marine Dock: A4-316 stainless steel eyebolt connects a yacht to a mooring cleat.

Stage Rigging: Alloy steel forged eyebolt (1/2″-13 UNC) suspends a 500-lb speaker array.

Safety Tips

✔ Never exceed the Working Load Limit (WLL).

✔ Avoid side-loading unless using a shoulder-type eyebolt.

✔ Inspect regularly for cracks, deformation, or corrosion.

Avis

Il n’y a pas encore d’avis.