OEM Customized Machined Screws CNC Steel Zinc Plated Black Oxide Nickel Plated

OEM Customized Machined Screws CNC Steel Zinc Plated Black Oxide Nickel Plated

- Description

- Avis (0)

Description

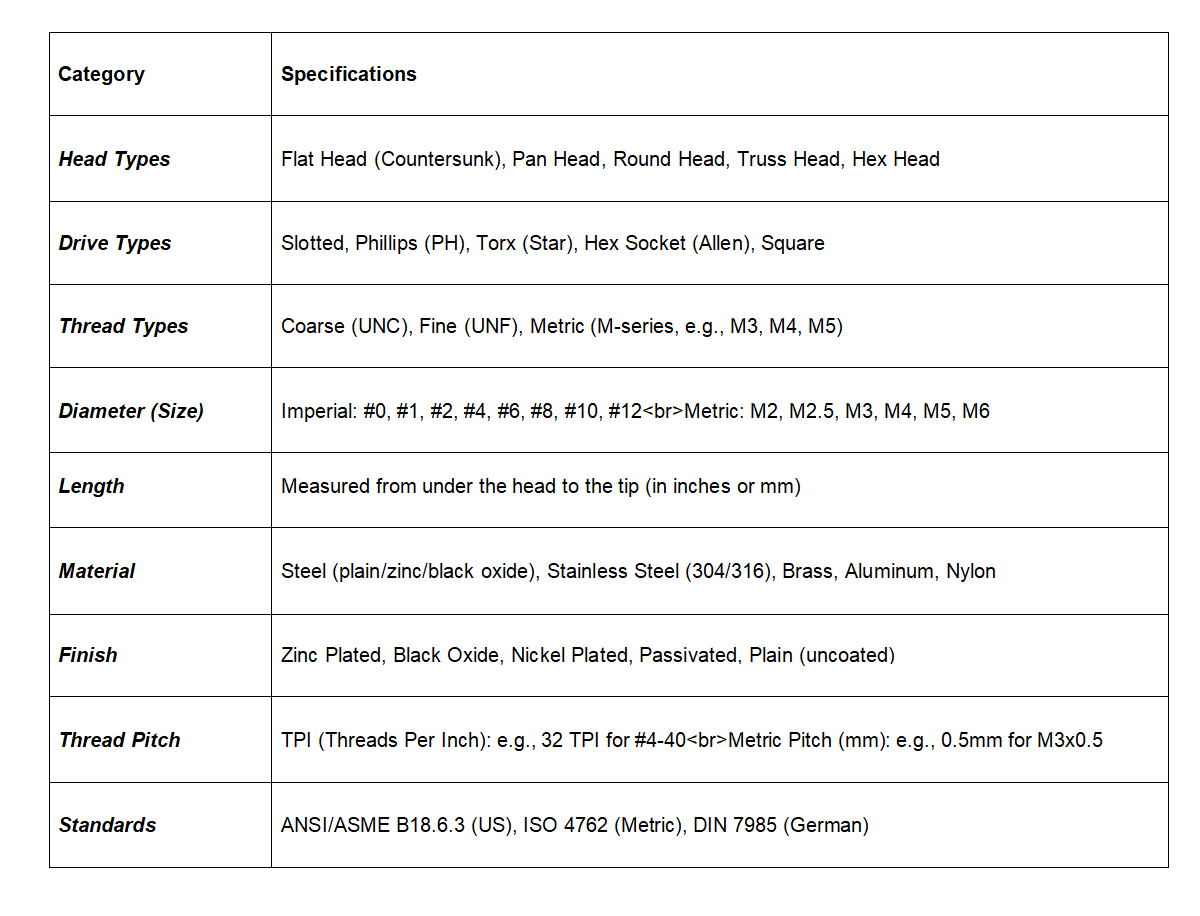

OEM Customized Machined Screws CNC Steel Zinc Plated Black Oxide Nickel Plated

Type

- Head Types

Flat Head (Countersunk)

Pan Head

Round Head

Truss Head

Hex Head

- Drive Types

Slotted

Phillips (PH)

Torx (Star)

Hex Socket (Allen)

Square

- Thread Types

Coarse Thread (UNC – Unified National Coarse)

Fine Thread (UNF – Unified National Fine)

Metric Thread (M-series, e.g., M3, M4, M5, etc.)

- Diameter (Size)

Imperial (inches): #0, #1, #2, #4, #6, #8, #10, #12, etc.

Metric (mm): M2, M2.5, M3, M4, M5, M6, etc.

- Length

Measured from under the head to the tip (in inches or mm).

- Material

Steel (plain, zinc-plated, black oxide)

Stainless Steel (304, 316)

Brass

Aluminum

Nylon (Plastic)

- Finish

Zinc Plated

Black Oxide

Nickel Plated

Passivated (for corrosion resistance)

Plain (uncoated)

- Thread Pitch (TPI or mm)

TPI (Threads Per Inch) for UNC/UNF screws (e.g., 32 TPI for #4-40).

Pitch (mm) for metric screws (e.g., 0.5mm for M3x0.5).

- Standards

ANSI/ASME B18.6.3 (US Standard)

ISO 4762 (Metric Standard)

DIN 7985 (German Standard)

Specification of Machined Screws

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Médical et dentaire : outils chirurgicaux, dispositifs implantables, microfixations.

Électronique : micro-connecteurs, boîtiers de capteurs, supports de circuits imprimés.

Aérospatiale et défense : supports légers, composants pour drones, fixations spéciales.

Automobile : Pièces pour l'injection de carburant, fixations personnalisées, composants pour véhicules électriques.

Pourquoi nous choisir ?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for JIT delivery and international clients.

Avis

Il n’y a pas encore d’avis.