Black Colorful Anodized Round Aluminum Unthreaded Spacers M2 M3 M4 M5 M6 M8

0 Sur 5

Black Colorful Anodized Round Aluminum Unthreaded Spacers M2 M3 M4 M5 M6 M8

Catégorie : Entretoises métalliques

Étiquettes : 2 inch metal spacers, 5/16 metal spacers, aluminum spacers, aluminum unthreaded spacers, cnc machined spacers, cnc machining spacers, flat metal spacers, large metal spacers, m8 metal spacers, Entretoises métalliques, Metal Spacers for Bolts, metal spacers for screws, round metal spacers

- Description

- Avis (0)

Description

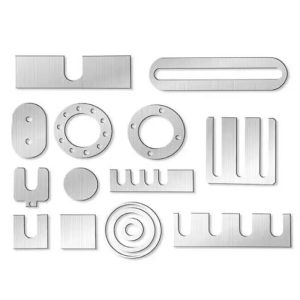

What is an Aluminum Unthreaded Spacer?

An Aluminum Unthreaded Spacer (also called a standoff or bushing) is a cylindrical tube made of aluminum, designed to create precise gaps, provide insulation, or maintain alignment between components in mechanical assemblies. Unlike threaded spacers, these have smooth inner and outer diameters with no threading, making them ideal for applications requiring free movement of bolts or shafts.

Specifications of Aluminum Unthreaded Spacers

Material

Aluminum Alloys (Common grades):

6061-T6 – High strength, good machinability, corrosion-resistant.

7075-T6 – Aerospace-grade, extremely strong but less corrosion-resistant.

2024-T3 – High strength-to-weight ratio, used in aircraft.

Pure Aluminum (1xxx series) – Excellent corrosion resistance but lower strength.

Surface Treatment

Anodizing (Type II or Type III Hardcoat) – Improves corrosion/wear resistance.

Chromate Conversion Coating (Alodine/Iridite) – Enhances corrosion protection.

Powder Coating – Adds color and extra durability.

Natural (Bare Aluminum) – Used when minimal oxidation is acceptable.

Standard Specifications

Inner Diameter (ID): 2mm to 50mm (custom sizes available)

Outer Diameter (OD): 4mm to 60mm

Length: 5mm to 200mm (or custom)

Tolerance: Typically ±0.1mm (precision machining available)

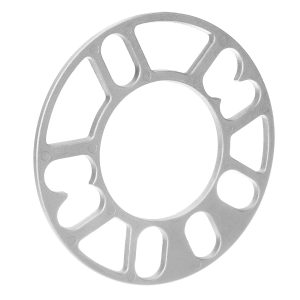

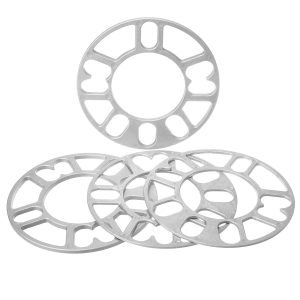

Applications of Aluminum Unthreaded Spacers

Electronics & PCB Mounting – Maintains spacing between circuit boards and chassis.

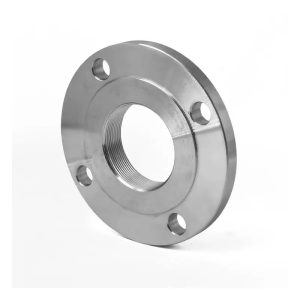

Automotive & Aerospace – Lightweight structural support in engines and airframes.

Robotics & Machinery – Ensures proper alignment of moving parts.

Renewable Energy – Solar panel framing and wind turbine assemblies.

Medical Devices – Used in imaging equipment and surgical tools for precision spacing.

Excellent Case: Drone Frame Assembly

Challenge

A drone manufacturer needed lightweight, high-strength spacers to separate carbon fiber plates while minimizing weight and preventing electrical conductivity (to avoid interference with onboard electronics). Steel spacers were too heavy, and plastic lacked sufficient strength.

Solution

Hardcoat-Anodized 6061-T6 Aluminum Spacers were selected because they:

Reduce weight vs. steel (~60% lighter).

Provide structural rigidity for high-vibration environments.

Anodizing prevents electrical conductivity between components.

Resist corrosion from moisture and outdoor exposure.

Result

Weight savings → Longer flight time and improved battery efficiency.

Enhanced durability – No deformation under stress.

No signal interference – Anodized layer acts as an insulator.

Lower production cost – Easier to machine than titanium or stainless steel.

This case demonstrates how aluminum unthreaded spacers optimize performance in high-tech applications like drones, balancing strength, weight, and functionality.

Would you like details on custom spacer designs or industry-specific standards?

Avis

Il n’y a pas encore d’avis.