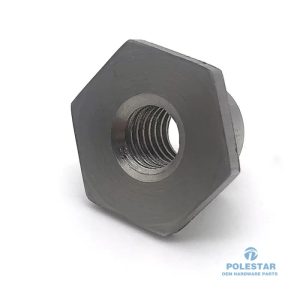

Industrial Grade Spring Nut Reliable Stainless Steel Strut Spring Channel Nut

0 Sur 5

Industrial Grade Spring Nut Reliable Stainless Steel Strut Spring Channel Nut

Catégorie : Écrous usinés

Étiquettes : 5/8 spring nut, channel spring nuts, CNC machined nut, CNC Machined Nuts, CNC machining nut, CNC Machining Nuts, cnc nut, cnc nuts, custom nut, custom nuts, m6 spring nuts, m8 spring nut, m8 spring nuts, machined nut, Écrous usinés, machining nut, Machining Nuts, metal spring nuts, special nut, Special Nuts, spring channel nut, spring nut, spring nut channel, spring nut m6, spring nuts, spring nuts stainless steel, stainless steel spring nut, strut channel spring nut, strut channel spring nuts, strut spring nut, strut spring nuts

- Description

- Avis (0)

Description

What is a Spring Nut?

A spring nut, also known as a speed nut or a sheet metal nut, is a unique type of fastener designed with one or more spring-like prongs. These prongs apply constant pressure against the sides of the bolt or screw thread, creating a strong, self-locking, and often vibration-resistant connection. They are primarily used to provide a threaded insert in thin materials, such as sheet metal, where tapping a thread directly is not feasible or strong enough. They are installed by pushing them into a pre-punched or drilled hole, where the prongs grip the backside of the panel, holding the nut securely in place for the screw to be driven in.

Materials

Spring nuts are manufactured from a variety of materials to suit different environmental and strength requirements. Common materials include:

Carbon Steel: The most common and economical option, often used in general industrial applications.

Stainless Steel: (Typically grades 304 or 316) Offers excellent corrosion resistance for harsh environments, including those exposed to moisture or chemicals.

Zinc Alloy: (Such as Zamak) Used for its good corrosion resistance and casting properties for more complex designs.

Brass: Provides good corrosion resistance and electrical conductivity.

Surface Finishes

Surface finishes are applied to enhance corrosion resistance and sometimes appearance.

Zinc Plating: The most standard finish for carbon steel nuts, offering good rust protection. It often comes with a clear (blue) or yellow (chromate) iridescent coating.

Phosphate Coating: Provides a corrosion-resistant base that is excellent for holding oil or paint.

Nickel Plating: Offers a bright, silvery appearance and good corrosion resistance.

Passivation: A chemical treatment for stainless steel to remove free iron from the surface and enhance its natural corrosion-resistant oxide layer.

Specifications

Spring nuts are defined by several key specifications:

Thread Size: Standard metric (e.g., M4, M5, M6) or imperial (e.g., #10-24, 1/4-20) screw threads.

Material Thickness: Designed to grip a specific range of panel thicknesses (e.g., 0.8mm – 2.0mm).

Prong Configuration: Can have two, three, or four prongs, which affects grip and load distribution.

Overall Dimensions: The height, width, and depth of the nut must fit the intended application space.

Application Fields

Due to their self-retaining and vibration-resistant nature, spring nuts are widely used in:

Automotive Industry: For securing interior trim panels, wiring harness clips, and various components on car bodies.

Electronics and Appliance Manufacturing: To assemble sheet metal casings for computers, ovens, washing machines, and control panels.

HVAC Systems: For attaching panels, ducts, and components in heating, ventilation, and air conditioning units.

Furniture Assembly: Especially in modular or flat-pack furniture where disassembly and reassembly are required.

General Metal Fabrication: Any application involving fastening to thin sheet metal.

Excellent Case: Automotive Door Panel Assembly

A prime example of an excellent spring nut application is in the assembly of an automotive door panel. A pre-formed sheet metal door frame has several punched holes. Spring nuts, designed for the specific thickness of the metal, are quickly pressed into these holes by an assembly line robot. Their spring prongs grip the back of the metal securely, providing a fixed, threaded anchor point.

Later in the assembly process, interior plastic trim panels are aligned and fastened onto the door frame. Workers use power drivers to quickly run screws through the plastic and directly into the pre-installed spring nuts. The spring nut’s design ensures a tight fit that resists loosening from the constant vibrations experienced while driving, ensuring the interior panel remains firmly and quietly in place for the life of the vehicle. This method is vastly faster, more secure, and more cost-effective than trying to tap threads into the thin door metal itself.

Avis

Il n’y a pas encore d’avis.