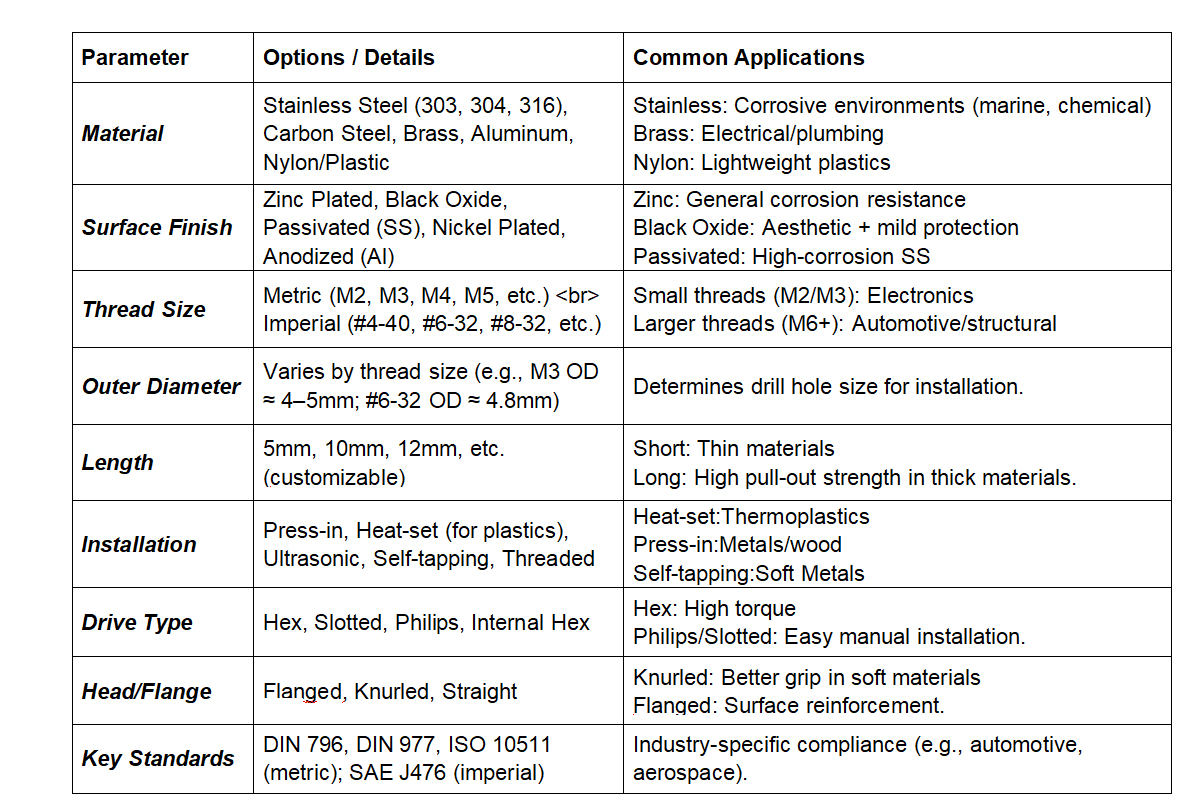

Custom Threaded Inserts Stainless Steel Carbon Steel Brass Aluminum Nylon Plastic

Custom Threaded Inserts Stainless Steel Carbon Steel Brass Aluminum Nylon Plastic Material Compatibility

- Description

- Avis (0)

Description

Custom Threaded Inserts Stainless Steel Carbon Steel Brass Aluminum Nylon Plastic

Materials

Threaded inserts are available in various materials to suit different applications:

Stainless Steel (e.g., 303, 304, 316) – Corrosion-resistant, high strength

Carbon Steel – High strength, often zinc-plated for corrosion resistance

Brass – Good conductivity, corrosion-resistant, softer than steel

Aluminum – Lightweight, corrosion-resistant, lower strength

Nylon/Plastic – Non-conductive, lightweight, used in soft materials

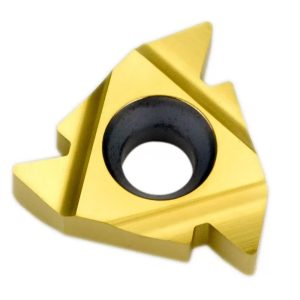

Surface Treatments/Finishes

To enhance durability and performance:

Zinc Plating – Common for steel inserts, improves corrosion resistance

Black Oxide – Provides mild corrosion resistance and aesthetic finish

Passivation (for stainless steel) – Enhances corrosion resistance

Nickel Plating – Improves wear resistance and appearance

Anodizing (for aluminum) – Increases corrosion and wear resistance

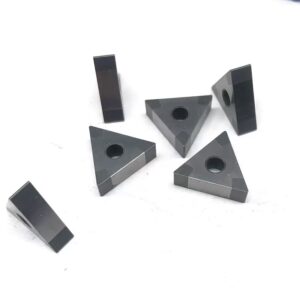

Applications

Threaded inserts are used in:

Plastic & Composite Materials – Reinforces threads in soft materials

Woodworking – Provides durable threads in wood (e.g., furniture, cabinetry)

Metal Fabrication – Used in thin metal sheets where direct threading is weak

Automotive & Aerospace – Lightweight and high-strength fastening

Electronics – Used in plastic casings for screws

Parameters

Core Competencies:

✅ Small CNC Machining – Producing miniature, complex parts (0.1mm–300mm) with tolerances down to ±0.005mm .

✅ Non-Standard Fasteners – Custom-designed screws, bolts, pins, and connectors for niche applications .

✅ Materials Expertise – Machining stainless steel, titanium, aluminum, plastics , and exotic alloys.

✅ End-to-End Solutions – From prototyping to high-volume production with strict ISO9001, IATF16949 compliance.

Key Industries Served:

Médical et dentaire : outils chirurgicaux, dispositifs implantables, microfixations.

Électronique : micro-connecteurs, boîtiers de capteurs, supports de circuits imprimés.

Aérospatiale et défense : supports légers, composants pour drones, fixations spéciales.

Automobile : Pièces pour l'injection de carburant, fixations personnalisées, composants pour véhicules électriques.

Pourquoi nous choisir ?

✔ Precision-First Approach : Leveraging 3-axis 4-axis CNC, Swiss lathes, and EDM for intricate geometries.

✔ Agile Customization : Rapid turnaround for low-volume batches and one-off prototypes .

✔ Quality Assurance : Rigorous inspection (CMM, optical comparators) and traceability .

✔Global Supply Chain : Reliable logistics for delivery and international clients.

Avis

Il n’y a pas encore d’avis.