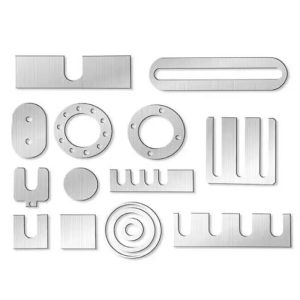

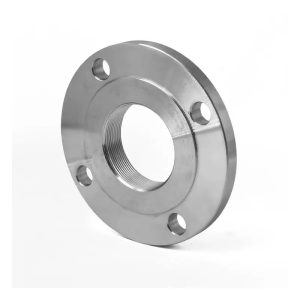

CNC Machined Metal Spacers with DLC Coating for LED and Solar Panel Mounting

0 out of 5

CNC Machined Metal Spacers with DLC Coating for LED and Solar Panel Mounting

دسته: Metal Spacers

برچسب: 1 2 inch metal spacers, 2 inch metal spacers, aluminum square spacers, black dlc coating, CNC Machined Parts, CNC Machining Metal Spacers, cnc metal spacers, custom dlc coating, DLC coating, dlc coating aluminum, dlc coating service, m8 metal spacers, Metal Spacers, metal spacers for screws, round metal spacers, sheet metal spacers, square metal spacers, titanium dlc coating

- توضیحات

- نظرات (0)

توضیحات

What are Metal Spacers?

Metal spacers are precision components used to create and maintain specific gaps or distances between two or more parts in mechanical assemblies. Metal spacers serve as rigid separators that provide accurate spacing while often bearing loads, transferring forces, or maintaining alignment in various industrial applications.

Materials:

Stainless steel (304, 316, 17-4PH) — valued for corrosion resistance

Aluminum (6061, 7075) — lightweight and easy to machine

Titanium (Grade 2, Grade 5) — high strength-to-weight ratio

Brass or bronze — excellent conductivity and wear resistance

Carbon steel — cost-effective with good mechanical properties

Nickel-based alloys (like Inconel) — ideal for extreme environments

Surface Treatments:

DLC (Diamond-Like Carbon) Coating, also referred to as S-D: ultra-hard, low-friction layer ideal for high-wear environments

Anodizing (mainly for aluminum) for enhanced corrosion protection

Passivation for stainless steel to improve oxide layer stability

Zinc or nickel plating for added surface protection

Black oxide for aesthetic and mild rust resistance

Powder coating for insulation and visual appeal

Specifications:

Diameter range: 1mm to 200mm

Thickness range: 0.1mm to 50mm

Tolerance: Typically ±0.01mm to ±0.1mm (can be tighter for precision applications)

Flatness: Usually within 0.005mm to 0.05mm

Parallelism: Typically 0.005mm to 0.03mm

Surface roughness: Ra 0.2μm to 3.2μm

Applications:

LED panel and solar panel mounting systems

Electronics (for PCB stand-offs or heat management)

Aerospace and automotive assemblies

Medical devices and instruments

Optical equipment (lens alignment, structural spacing)

Industrial machinery (shock isolation, wear prevention)

Excellent Use Case: Aerospace Turbine Engine Assembly

In modern jet engine manufacturing, precision stainless steel spacers with DLC coating play a critical role in compressor section assembly. These spacers maintain exact blade clearances while withstanding extreme temperatures (up to 600°C) and rotational forces (up to 15,000 RPM).

Key benefits in this application:

The DLC coating reduces friction between rotating components by 40% compared to uncoated spacers

Maintains dimensional stability under thermal cycling

Prevents micro-welding and galling between titanium alloy components

Extends maintenance intervals by 3-5 times compared to traditional spacer solutions

Contributes to overall engine efficiency by maintaining precise tolerances over extended service life

نقد و بررسیها

هنوز بررسیای ثبت نشده است.